Energy savings

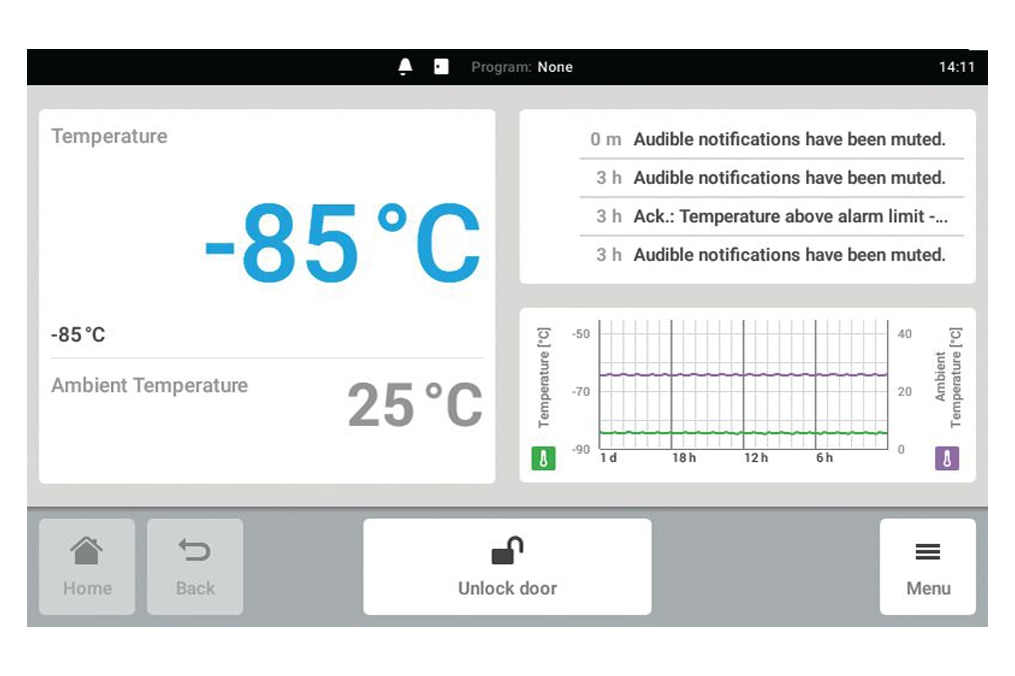

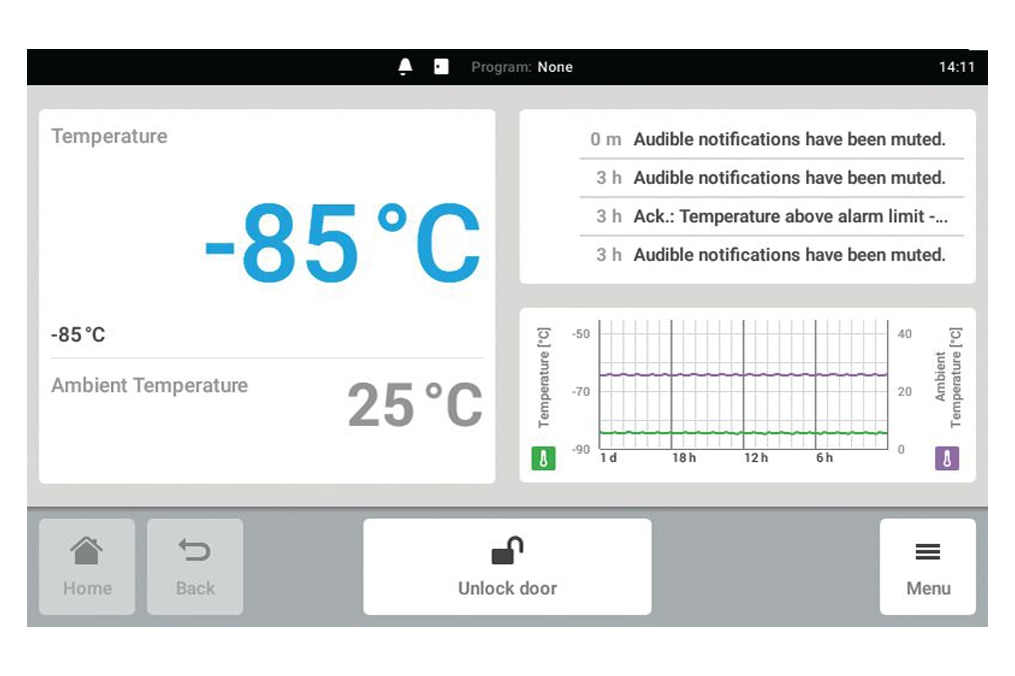

Eco-friendly ULT freezers are designed to help you saving energy and reducing your carbon footprint without any compromise in sample security. Keep in mind, reliable -80°C storage conditions require energy based on physical law. Smaller compressor systems require less energy but at some level of scale reduction, these smaller systems become non-dynamic. This means, the -80°C within the freezer are rarely met anymore and the recovery rates after door openings expand to several hours. As a result, the high value sample within the ULT freezer may suffer from inadequate temperature conditions.

Cooling liquids

The coolant or cooling liquid within a ULT freezer is used to cool down and to regulate the temperature. To reduce global warming, there is a clear tendency towards switching from classic cooling liquids as R508B and R404A to green or natural cooling (e.g. R170, R290). These green coolants are future-proof and have a very low Global Warming Potential (GWP) of nearly zero. This is also supported by European Union Regulation (EU_517/2014).

Eppendorf launched its first ULT freezer with green cooling in 2008, far earlier than most of our competitors. We now have more than10 years of experience with these coolants in R&D, production, logistics, and service in the field.

Longevity

The longer the life of a freezer, the more favorable for you as an user and for our environment. The price often plays a decisive role when purchasing a new freezer. Keep in mind the potential life time of the instrument. What about the cost-of-ownership over the years? Extend the life of your freezer by regular cleaning and inspection, regular maintenance, and repair and exchange of spare parts.

Research & Development

Production

Logistics

Marketing/Sales

Usage

Disposal

Global warming is a challenge for mankind on earth. Sustainability discussions primarily focus on energy consumption of devices. Even environmentally friendly and energy efficient ultra-low temperature freezers, also known as ULT freezers, traditionally consume a large amount of energy as they maintain extremely low temperatures 24 hours a day, 7 days a week, for years. -80 °C are needed for storage of many high-value samples – how can the usage of ULT freezers be optimized? How can the energy efficiency of storage processes be improved?

The International Institute for Sustainable Laboratories (I2SL) and My Green Lab partner to reward the best concept to improve cold storage regarding sustainability:

The annual Laboratory Freezer Challenge

It’s easy to participate - ULT freezer users are invited to compete with colleagues from around the globe. The users can earn points by taking actions from Good Management Practices, Temperature Tuning, and other areas, as well as for sharing information about best practices.

Awards will be given to those who have done the most to save energy and improve their sample storage.

As major global freezer supplier, Eppendorf sponsors this challenge since 2018 to support improving the sustainability of ULT storage in the labs.

More information in the Freezer Challenge at https://www.freezerchallenge.org/