MENÜ

AT | EUR

AT | EUR

Es konnten keine Ergebnisse gefunden werden.

Such-Empfehlungen

BioBLU® f Single-Use Bioreactors

BioBLU f Single-Use Bioreactors Group 0.3f, 1f, 3f

BioBLU f Single-Use Vessels für mikrobielle Anwendungen

Einweglösungen für Anwendungen im kleinen und Labormaßstab mit einem Arbeitsvolumen in einem Bereich von 65 mL bis 3,75 L. Fermentationsprozesse haben hohe Anforderungen an Stofftransfer und Wärmeableitung. Dank der bewährten Rührkesselkonstruktion, des leistungsstarken Überkopfantriebs mit Rushton-Typ-Rührern und effektiver Kühlung erfüllen die BioBLU f-Bioreaktoren diese Anforderungen.

Einweglösungen für Anwendungen im kleinen und Labormaßstab mit einem Arbeitsvolumen in einem Bereich von 65 mL bis 3,75 L. Fermentationsprozesse haben hohe Anforderungen an Stofftransfer und Wärmeableitung. Dank der bewährten Rührkesselkonstruktion, des leistungsstarken Überkopfantriebs mit Rushton-Typ-Rührern und effektiver Kühlung erfüllen die BioBLU f-Bioreaktoren diese Anforderungen.

BioBLU 0.3f Single-Use Bioreactor

BioBLU f Single-Use Bioreactors for fermentation applications

Single-use solutions for small and bench scale fermentation processes.

Single-use solutions for small and bench scale fermentation processes.

Produktinformationen

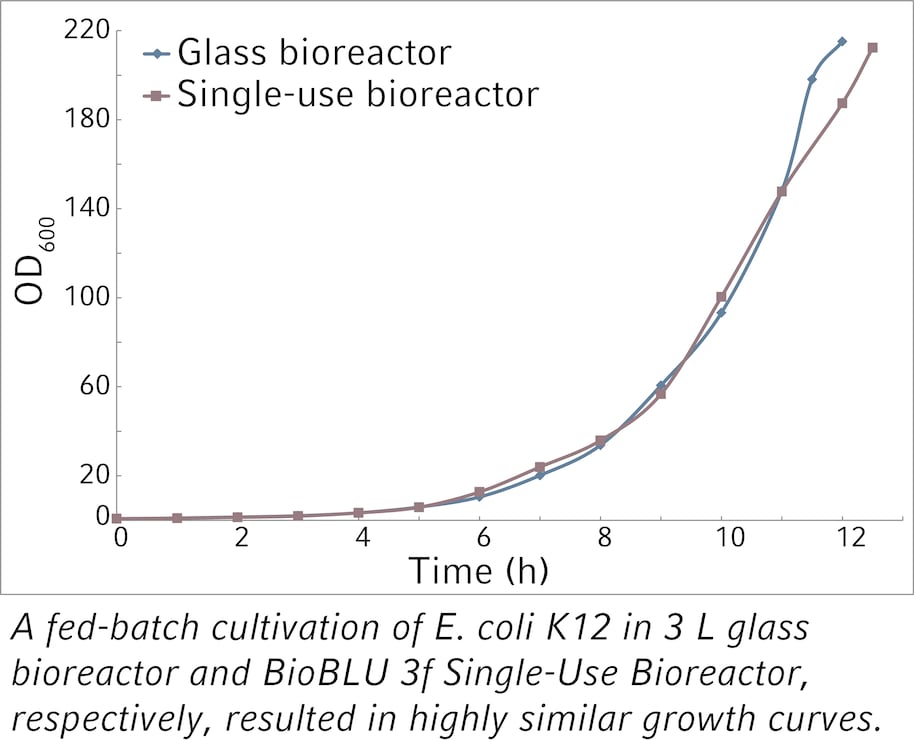

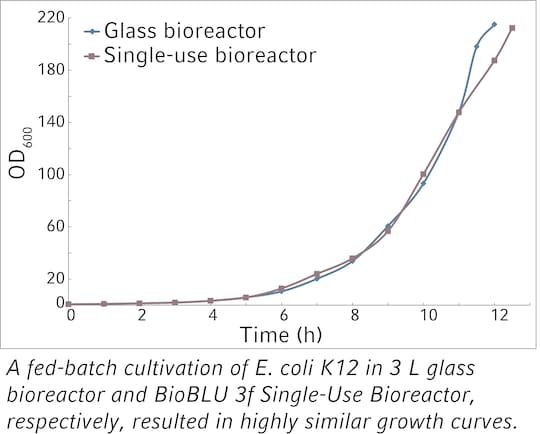

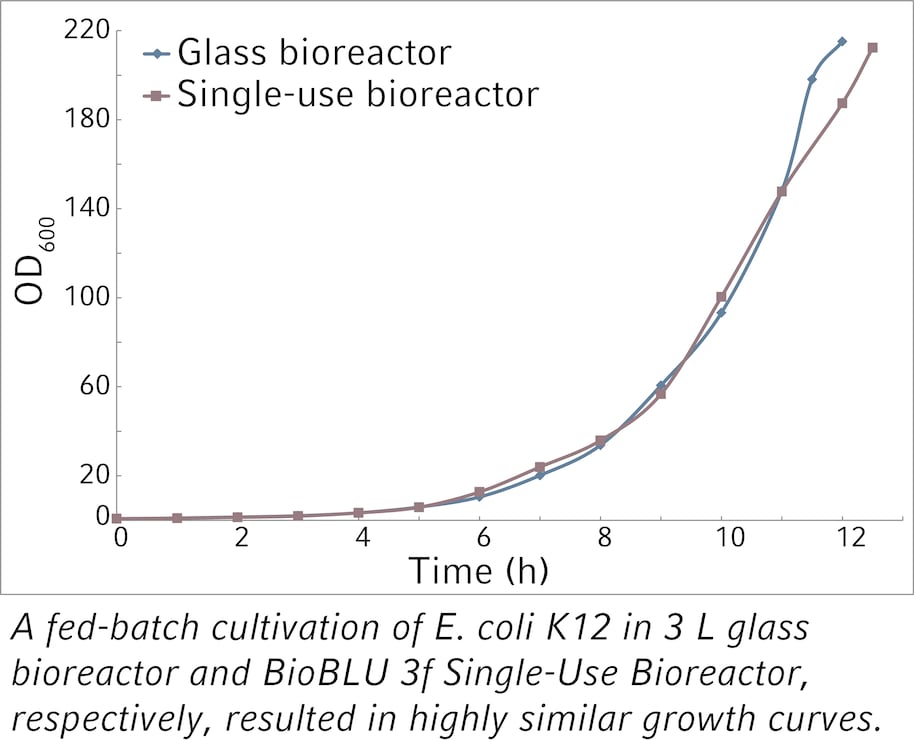

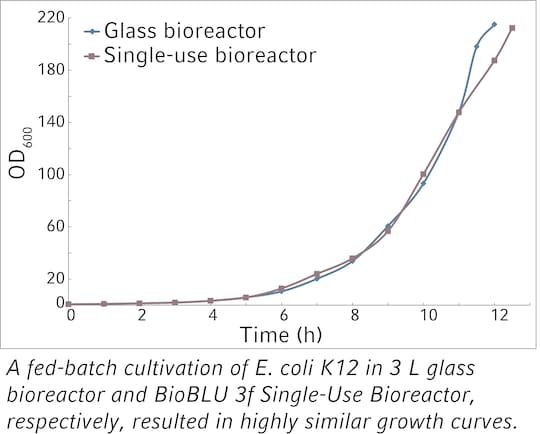

BioBLU f Single-Use Bioreactors are rigid-walled stirred-tank bioreactors specifically designed for robust microbial applications using bacteria, yeasts, and fungi. The scalable BioBLU f portfolio covers a working volume range of 65 mL – 3,75 L. The rigid wall stirred tank design mimics traditional bioreactors and supports effective mixing and mass transfer making them suitable for high-cell density fermentation.BioBLU 3f

Dokumente zum Download finden Sie weiter unten auf der Seite

Produkte (7)

Zubehör (3)

7 Produkte

Katalog-Nr.

1386100100

|

Katalog-Nr.

1386101100

|

Katalog-Nr.

1386110200

|

Katalog-Nr.

1386113000

|

Katalog-Nr.

1386110300

|

Katalog-Nr.

1386113100

|

Katalog-Nr.

1386000900

|

Mehr Produkte anzeigen

Zum Warenkorb hinzugefügt

Produktinformationen

Applikation

Eigenschaften

The BioBLU Single-Use Bioreactors for microbial applications at a glance:

The rigid wall stirred tank design mimics traditional bioreactors and supports effective mixing and mass transfer making them suitable for high-cell density fermentation.

• BioBLU 0.3f (working volume 65 – 250 mL)

• BioBLU 1f (working volume 250 mL – 1,25 L)

• BioBLU 3f (working volume 1,25 L – 3,75 L)

The BioBLU Single-Use Bioreactors are compatible with the small and bench-scale bioprocess controllers from Eppendorf and selected third-party controllers.

Bioreactor body and head plate

• Stirred-tank design: The stirred-tank design offers reliability scalability and facilitates the easy replacement of traditional glass bioreactors.

• Equipment: BioBLU Single-Use Bioreactors are assembled with sparger, overlay, gas filters for inlet and exhaust as well as penetrations for pH, DO, and temperature sensors, liquid additions, sampling, and harvest. All head plate ports are clearly marked for ease of use. Spare Pg 13.5 ports can be equipped with single-use septa, tri-ports and compression fitting adaptors for more flexibility.

• Sterilization: BioBLU 0.3f and 1f Single-Use Bioreactors are delivered sterile. Irradiated by > 15 kGy (β) or > 25 kGy (X-ray). SAL-level 10-6 for X-ray irradiated BioBLU® Single-Use Bioreactors. The BioBLU 3f Single-Use Bioreactor is not presterilized and is autoclavable.

Suitable for high cell densities

BioBLU f Single-Use Bioreactors support the high mass transfer and heat removal requirements of fermentation processes.

• Motor: Powerful overhead drives enable high agitation speeds. Sealed magnetic drive with fully enclosed bearings maintain vessel sterility.

• Baffles: Interior baffles aid mixing and mass transfer. The baffles of the BioBLU 1f additionally provide efficient heat removal through active cooling.

• Impellers: Multiple Rushton-type impellers for efficient mixing and mass transfer.

• Cooling: Smart solutions for cooling using cooling baffles or cooling fingers.

• Exhaust treatment: Effective liquid-free exhaust condensation (Peltier), electric heater band or water-cooled exhaust treatment.

Mehr lesen

Weniger lesen

- Cultivation of bacteria, yeasts, and fungi.

- Suitable for high-cell density fermentation.

- For the cultivation of human and animal cells we offer the BioBLUc Single-Use Bioreactor product line.

- Single-use, stirred-tank, rigid-walled bioreactors available in sizes ranging from 65 mL to 3.75 L working volume

- Designed for high-density fermentation processes

- Multiple Rushton-type impellers for efficient mixing and mass transfer

- Sealed magnetic drive with fully enclosed bearings maintain vessel sterility

- Baffles for excellent mixing and mass transfer

- Bioreactors are assembled with sparger, gas filters for inlet and exhaust as well as penetrations for pH, DO, temperature, liquid additions, sampling, and harvest

- For use with Eppendorf benchtop bioreactor systems

- Adaptor kits for legacy bioreactor controllers available