MENU

MY | MYR

MY | MYR

No results found

Search Suggestions

Optimizing Plasmid Yields in Shake Culture

Lab Academy

- Molecular Biology

- Microbiology

- Cell Culture

- Efficiency

- BioNews article

Recombinant plasmid DNA is produced in bacterial cultures, mostly in E. coli. Plasmid yield and quality depend on multiple factors, including the insert, the selection of host strain, the vector design, and the methodology chosen for cultivation and downstream purification. Here, we focus on how to optimize E. coli shake flask cultures examining the influence of culture media, vessel design, fill volume, and shaking speed on bacteria and plasmid yields. We illustrate how larger production range can be obtained by using the appropriate combination between a large incubated shaker, optimized culture conditions, and specifically designed culture flasks

Introduction

Plasmids serve as vehicles in genetic engineering either to clone and amplify DNA fragments, such as genes, or express recombinant proteins. Plasmid DNA (pDNA) can be easily genetically manipulated, produced in E. coli in large amounts and a variety of ready-to-use solutions allows easy subsequent downstream purification. Depending on the application, pDNA production ranks from research laboratory scale (up to a few mg) to industrial scales (mg to g scales). Here, we will examine the impact of cultivation with focus on high yield pDNA production in 2.5 L Ultra Yield® flasks.

Materials and methods

E. coli DH5α and JM109 were transformed with pUC19 plasmid and pGEM® -3Z. Glycerol stocks were stored at −80 °C. Lennox-Broth (LB) medium and modified TB was prepared and freshly supplemented with ampicillin and an anti-foam. All experiments were inoculated with the same start amount of 1 % (v/v) from a liquid seed culture and run in triplicates. Experiments were performed in the Eppendorf Innova® S44i with 25 mm orbit at 37 °C using Erlenmeyer flasks (baffled and unbaffled) and Ultra Yield flasks (Thomson). Bacteria densities were measured by OD600 nm, biomasses were determined from harvested culture samples and pDNA was isolated and measured by OD260 nm.

Results and discussion

Impact of flask design

Shake flasks are the most common laboratory-scale cultivation vessels for production of plasmids. The choice of the adequate flask design is depending on the organism’s oxygen requirements and the individual application needs. Different shake flask designs are available nowadays to increase the oxygen transfer to the culture (Fig. 1).

Plasmids serve as vehicles in genetic engineering either to clone and amplify DNA fragments, such as genes, or express recombinant proteins. Plasmid DNA (pDNA) can be easily genetically manipulated, produced in E. coli in large amounts and a variety of ready-to-use solutions allows easy subsequent downstream purification. Depending on the application, pDNA production ranks from research laboratory scale (up to a few mg) to industrial scales (mg to g scales). Here, we will examine the impact of cultivation with focus on high yield pDNA production in 2.5 L Ultra Yield® flasks.

Materials and methods

E. coli DH5α and JM109 were transformed with pUC19 plasmid and pGEM® -3Z. Glycerol stocks were stored at −80 °C. Lennox-Broth (LB) medium and modified TB was prepared and freshly supplemented with ampicillin and an anti-foam. All experiments were inoculated with the same start amount of 1 % (v/v) from a liquid seed culture and run in triplicates. Experiments were performed in the Eppendorf Innova® S44i with 25 mm orbit at 37 °C using Erlenmeyer flasks (baffled and unbaffled) and Ultra Yield flasks (Thomson). Bacteria densities were measured by OD600 nm, biomasses were determined from harvested culture samples and pDNA was isolated and measured by OD260 nm.

Results and discussion

Impact of flask design

Shake flasks are the most common laboratory-scale cultivation vessels for production of plasmids. The choice of the adequate flask design is depending on the organism’s oxygen requirements and the individual application needs. Different shake flask designs are available nowadays to increase the oxygen transfer to the culture (Fig. 1).

Read more

Read less

Fig. 1 (from left to right): Erlenmeyer flask design classic (unbaffled) and baffled; Ultra Yield flasks

Depicted flask designs were examined to select the best suited one for high yield production in larger volume flasks. The Ultra Yield design performed slightly better than the standard baffled flask (data shown in original Application Note 449 ) and was used for subsequent tests.

Impact of media composition

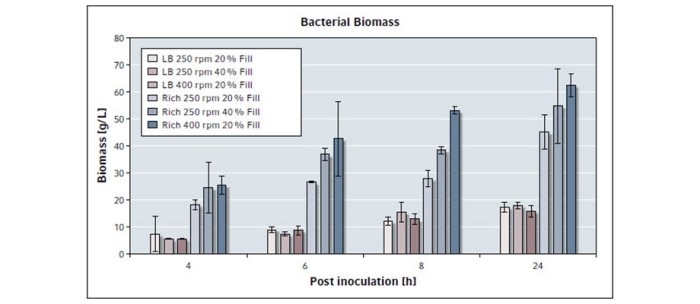

The media supplies the culture with nutrients, such as proteins, minerals, vitamins, and carbohydrates. Figures 2 and 3 show clearly the influence of the media composition on biomass and pDNA yields. The overall bacterial biomass in the enriched TB media resulted in a 2-4-fold higher biomass, depending on fill volume and shaking speed applied, compared to classic LB media (Fig. 2).

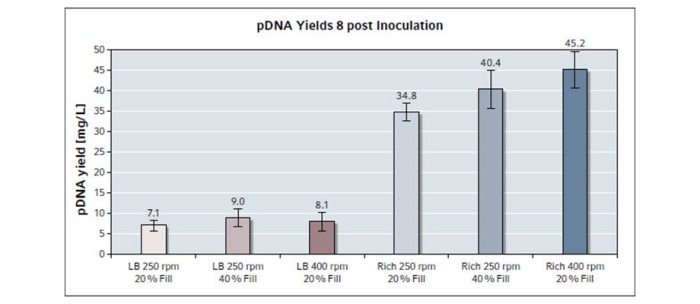

The resulting pDNA yields gave similar results, with 4-5-fold higher pDNA yields when cultivated in the TB formula (Fig. 3). Classic LB medium formulations are excellent for routine molecular biology applications, but yields saturate at an OD600 ≤ 7, when utilizable carbon sources are exhausted. To achieve high yields with ODs ≥ 20 a buffered nutrient rich medium containing glycerol as additional carbohydrate source is better suited.

Impact of media composition

The media supplies the culture with nutrients, such as proteins, minerals, vitamins, and carbohydrates. Figures 2 and 3 show clearly the influence of the media composition on biomass and pDNA yields. The overall bacterial biomass in the enriched TB media resulted in a 2-4-fold higher biomass, depending on fill volume and shaking speed applied, compared to classic LB media (Fig. 2).

The resulting pDNA yields gave similar results, with 4-5-fold higher pDNA yields when cultivated in the TB formula (Fig. 3). Classic LB medium formulations are excellent for routine molecular biology applications, but yields saturate at an OD600 ≤ 7, when utilizable carbon sources are exhausted. To achieve high yields with ODs ≥ 20 a buffered nutrient rich medium containing glycerol as additional carbohydrate source is better suited.

Read more

Read less

Fig. 2: Bacterial biomass (DH5α with pUC19 plasmid) in 2.5 L Ultra Yield flasks with different media, working volumes, and agitation speeds incubated at 37 °C

Fig. 3: pDNA yields (DH5α with pUC19 plasmid) in 2.5 L Ultra Yield flasks with different media, working volumes, and agitation speeds incubated at 37 °C

Impact of agitation speed

Typical shaking speeds are around 200 – 250 rpm. The positive impact of using a higher shaking speed is clearly demonstrated here in the TB media culture. The best results in biomass and pDNA yields were obtained in the cultures with 20 % fill incubated at 400 rpm. Compared to the standard agitation at 250 rpm, an increase to 400 rpm resulted in a nearly 2-fold higher biomass after 8 hours (Fig. 2) and a ~30 % increase in pDNA yields (Fig. 3).

Impact of working volume

A larger culture volume can also improve plasmid yields. The higher fill volume (at same shaking speed of 250 rpm) resulted in higher yields. Doubling the culture volume from 20 to 40 % resulted in a ~1.4 higher biomass (Fig. 2) and an increase of pDNA yields > 15 % after 8 hours (Fig. 3).

This is a bit unexpected, as usually a higher fill results in oxygen limitation. One explanation may be the specific baffled design and flow behavior in the specialized Ultra Yield designs.

Impact of the shaker design

To incubate this many flasks in parallel, large capacity stackable incubated shakers are the product of choice for high yield plasmid production. Depending on fill volume, a volume between 19.5 L (20 % fill) and 45 L (40 % fill) in 2.5 Liter Ultra Yield flasks can be reached e.g. in a triple stacked large capacity shaker as the Eppendorf Innova S44i. The shaker should operate reliably with high weight loads also at high shaking speeds.

Shakers with a multi-shaft drive system stabilize the platform on more than one point, providing maximum stability also at high speed/load scenarios. To compensate the centrifugal force created by the liquid mass, the shaker drive should in addition be equipped with a good counterbalance to prevent imbalance situations and prevent the shaker from wearing out over time.

Conclusion

Optimizing the bacteria cultivation conditions can contribute to enhancing pDNA yields. Using a nutrient rich medium instead of LB, baffled or specialized flask design like Ultra Yield flasks, and an increase in shaking speed can positively impact bacterial growth and thus subsequent production yields. Hence, selection criteria for shakers should be, beside capacity, a robust drive and counterbalance system to operate reliably with high weight and shaking speeds.

Note: Eppendorf SE reserves the right to modify its products and services at any time. This Application Note is subject to change without notice. Although prepared to ensure accuracy, Eppendorf SE assumes no liability for errors, or for any damages resulting from the application or use of this information. Viewing Application Notes alone cannot as such provide for or replace reading and respecting the current version of the operating manual.

Typical shaking speeds are around 200 – 250 rpm. The positive impact of using a higher shaking speed is clearly demonstrated here in the TB media culture. The best results in biomass and pDNA yields were obtained in the cultures with 20 % fill incubated at 400 rpm. Compared to the standard agitation at 250 rpm, an increase to 400 rpm resulted in a nearly 2-fold higher biomass after 8 hours (Fig. 2) and a ~30 % increase in pDNA yields (Fig. 3).

Impact of working volume

A larger culture volume can also improve plasmid yields. The higher fill volume (at same shaking speed of 250 rpm) resulted in higher yields. Doubling the culture volume from 20 to 40 % resulted in a ~1.4 higher biomass (Fig. 2) and an increase of pDNA yields > 15 % after 8 hours (Fig. 3).

This is a bit unexpected, as usually a higher fill results in oxygen limitation. One explanation may be the specific baffled design and flow behavior in the specialized Ultra Yield designs.

Impact of the shaker design

To incubate this many flasks in parallel, large capacity stackable incubated shakers are the product of choice for high yield plasmid production. Depending on fill volume, a volume between 19.5 L (20 % fill) and 45 L (40 % fill) in 2.5 Liter Ultra Yield flasks can be reached e.g. in a triple stacked large capacity shaker as the Eppendorf Innova S44i. The shaker should operate reliably with high weight loads also at high shaking speeds.

Shakers with a multi-shaft drive system stabilize the platform on more than one point, providing maximum stability also at high speed/load scenarios. To compensate the centrifugal force created by the liquid mass, the shaker drive should in addition be equipped with a good counterbalance to prevent imbalance situations and prevent the shaker from wearing out over time.

Conclusion

Optimizing the bacteria cultivation conditions can contribute to enhancing pDNA yields. Using a nutrient rich medium instead of LB, baffled or specialized flask design like Ultra Yield flasks, and an increase in shaking speed can positively impact bacterial growth and thus subsequent production yields. Hence, selection criteria for shakers should be, beside capacity, a robust drive and counterbalance system to operate reliably with high weight and shaking speeds.

Note: Eppendorf SE reserves the right to modify its products and services at any time. This Application Note is subject to change without notice. Although prepared to ensure accuracy, Eppendorf SE assumes no liability for errors, or for any damages resulting from the application or use of this information. Viewing Application Notes alone cannot as such provide for or replace reading and respecting the current version of the operating manual.

Read more

Read less