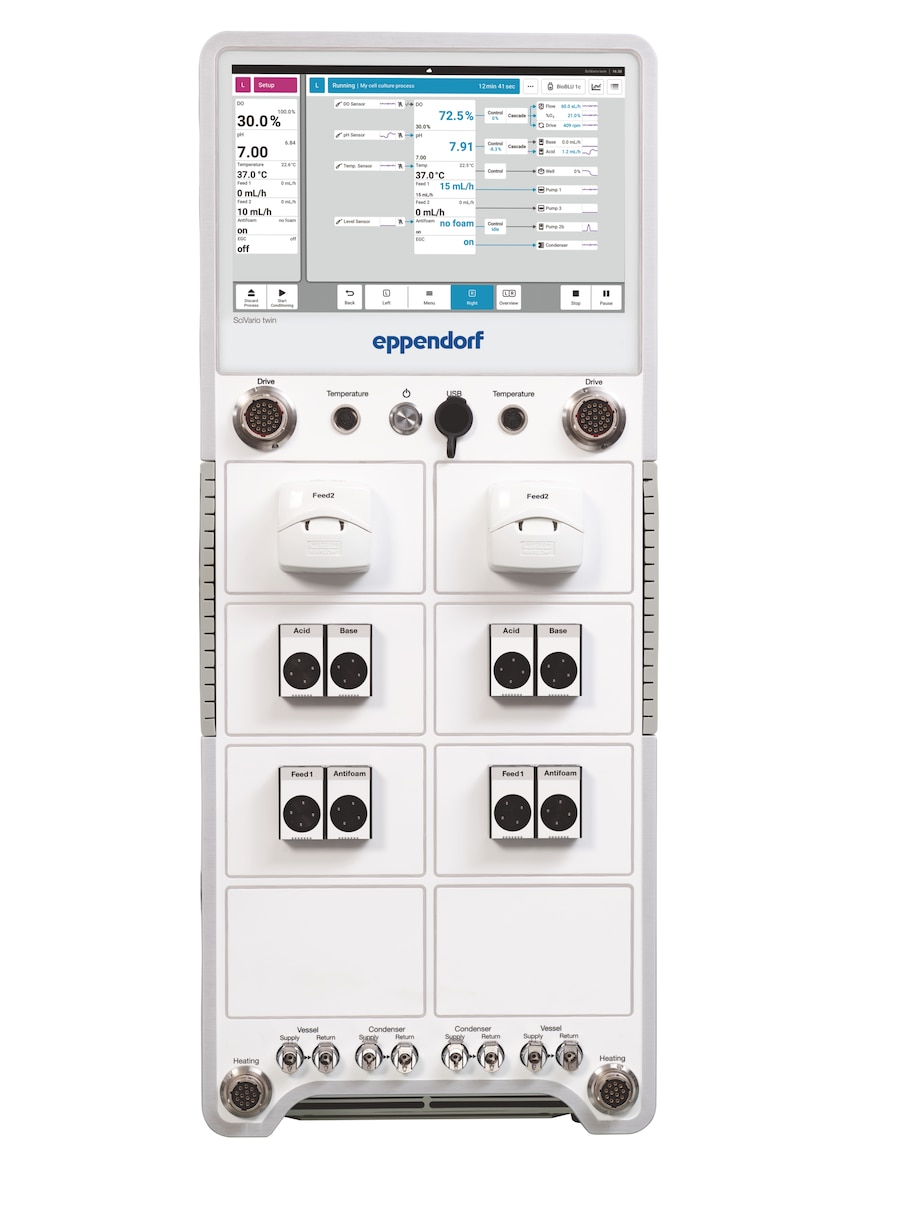

- Customizable and flexible thanks to the innovative bay-drawer concept for further extension and reconfiguration

- Integrated digital sensor technology (Mettler Toledo® ISM® and Hamilton ARC®), supporting analog sensors for pH and DO and optical DO sensors

- Optional PreSens® optical DO sensor technology for BioBLU Single-Use Bioreactors

- Variable speed pumps for accurate liquid addition and operation in batch and fed-batch mode

- Wide range TMFC to allow for individual mixing of air, N2, O2, and CO2 to headspace and/or submerged aeration

- Individual or parallel operation of two glass and/or BioBLU Single-Use Bioreactors, in any combination of bioreactor types

- Compact design, 16-40 cm of benchspace needed per vessel

- Cable management guides for a clean and tidy setup

- Temperature control block for advanced and user-friendly temperature control or temperature control via heat blankets and cooling fingers (benchtop bioreactors)

- Compatible with DASware® control software and BioNsight® cloud software

- Compatible with Bioprocess Autosampler

-

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Pipette Tips

- Bottle-Top Dispensers

- Pipette Controllers

- Dispenser & Pipette Accessories

- Automated Pipetting

- Automation Consumables

- Automation Accessories

- Liquid Handler & Pipette Services

- Home

- Products

- Bioprocess

- Bioprocess Controllers

- SciVario® twin

- 7600100001

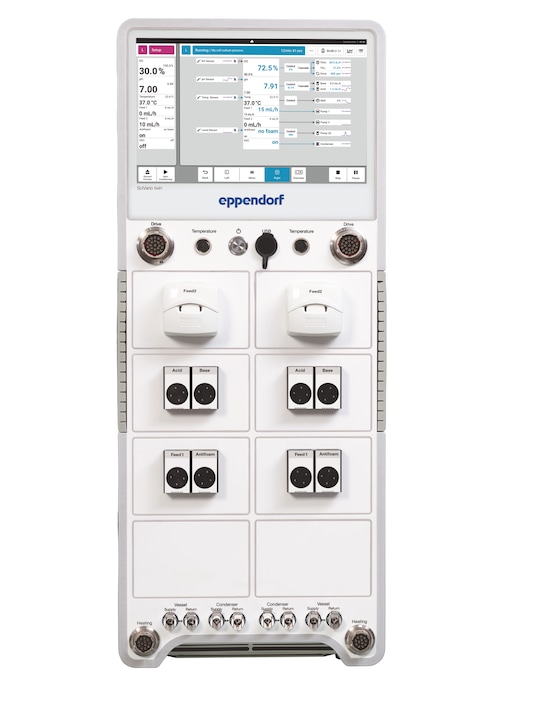

SciVario® twin Fermenter/Bioreactor Control System

SciVario twin cropped, front, grey lines

0.2 – 3.8 L working volume (autoclavable)

0.06 – 40 L working volume (single-use)

Technical Data

Features

Technical Data

| Specifications | SciVario® twin Fermenter/Bioreactor Control System |

|---|

| Power supply | 100 – 240 V, 50/60 Hz |

| Max. power consumption | 1750 W |

| Dimensions (W × D × H) | 30.6 × 34 × 75 cm / 12.0 × 13.4 × 29.5 in |

| Product weight | 43.1 kg |

| Bacteria/Yeast/Fungi | yes |

| Mammalian/Animal | yes |

| Insect | optional |

| Interchangeable Vessels | yes |

| Validatable | no |

| Stem cells | yes |

|

Bioreactor type |

|

| Vessels | Glass/single-use vessels |

| Total volume | 1.3 L to 3.8 L for all variants, up to 40 L for single-use cell culture |

|

Agitation |

|

| Drive | Direct/magnetic overhead drive |

| Speed ranges | 60 – 1,600 rpm/25 – 1,250 rpm/25 – 1,900 rpm |

|

Gassing |

|

| Gas supply | TMFC; overlay and/or sparger |

| Standard gas flow rates | 0.1 – 1,200 sL/h |

| Standard gas mixing | Air, N2, O2 and/or CO2 |

|

Feeding |

|

| Feed lines per vessel | Up to 6 |

| Standard feed rates (depending on tube diameter) | 0.01 – 500 mL/h (small pump), 15 – 6000 mL/h (large pump) |

|

Monitoring and Control |

|

| Exhaust condensation | Liquid-free (Peltier) or water-based |