-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifugation Consumables

- Accessories

- Tubes

- Plates

- Device Management Software

- Sample and Information Management

- IVD Products

CryoCube® F101h - ULT Freezer

Eppendorf CryoCube F101h ULT freezer: Compact freezer

Eppendorf CryoCube F101h ULT freezer: Freezer fits below the bench

Eppendorf CryoCube F101h ULT freezer: Door handle with key

Eppendorf CryoCube F101h ULT freezer: Easy access to filter

Eppendorf CryoCube F101h ULT freezer: Comfortable removal of inner doors for cleaning

Eppendorf CryoCube F101h ULT freezer: -80°C below the bench

Eppendorf CryoCube F101h ULT freezer: Removing samples

Eppendorf CryoCube F101h ULT freezer: Independent second sensor set

Eppendorf CryoCube F101h ULT freezer: Digital sample management

Eppendorf CryoCube F101h ULT freezer: Connectivity via VisioNize Box

Air Vent port detail

Your Personal -80°C Freezer - CryoCube® F101h

Videos not loading, because cookies have been rejected. Change your

Product Information

Looking for a personal under-the-bench ULT freezer?The Eppendorf CryoCube F101h ultra-low temperature (ULT) freezer combines compact design with real -80 °C to offer long-lasting and reliable ULT technology for safe sample storage.

-

Learn more about sustainability at Eppendorf - incl. how to recognize a sustainable ULT freezer

-

Selection tool for Eppendorf racks (please use Mozilla FireFox)

You will find additional download material at the bottom of this page

Products (1)

epServices (8)

Accessories (9)

VisioNize (7)

1 Products

|

Show more Products

Product Information

Technical Data

Applications

Features

Product Information

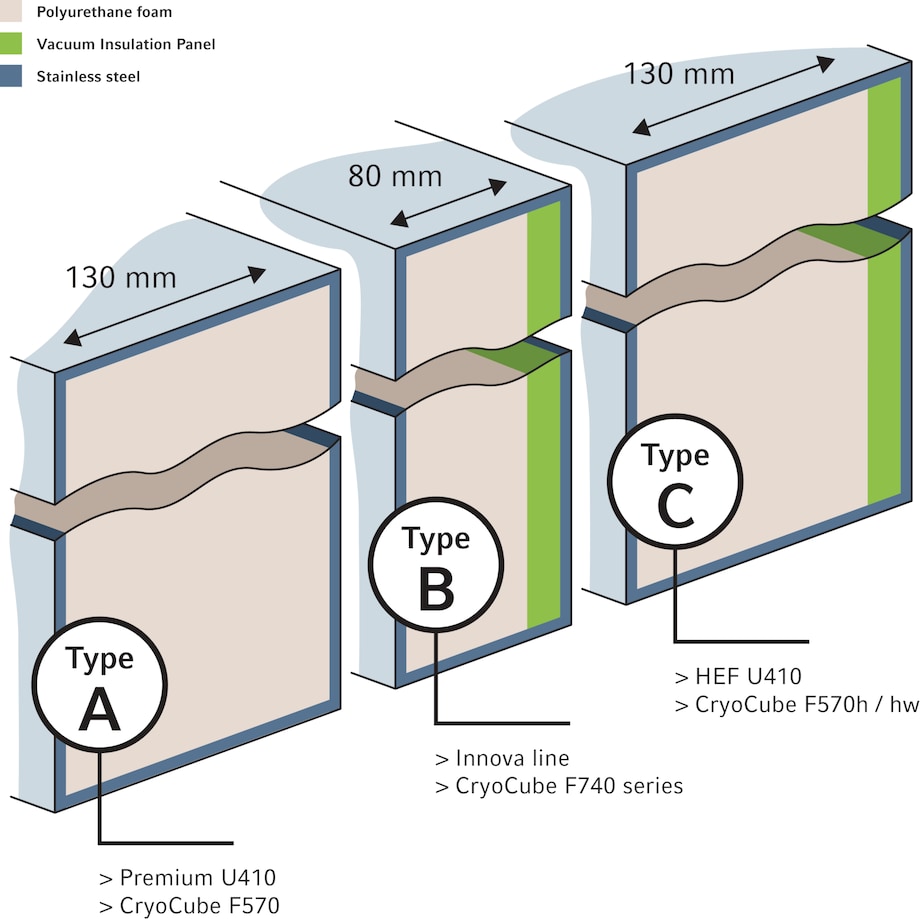

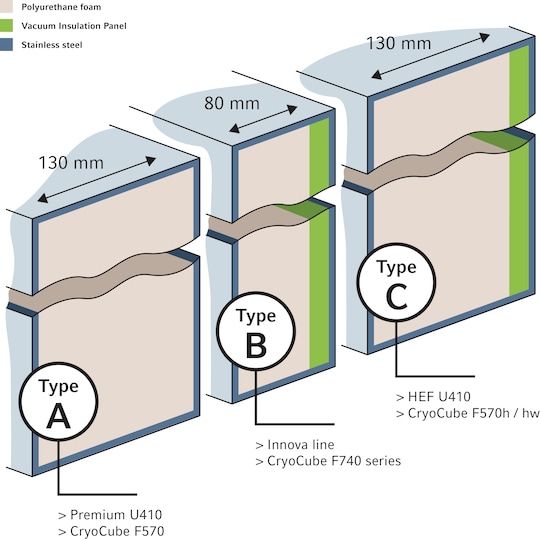

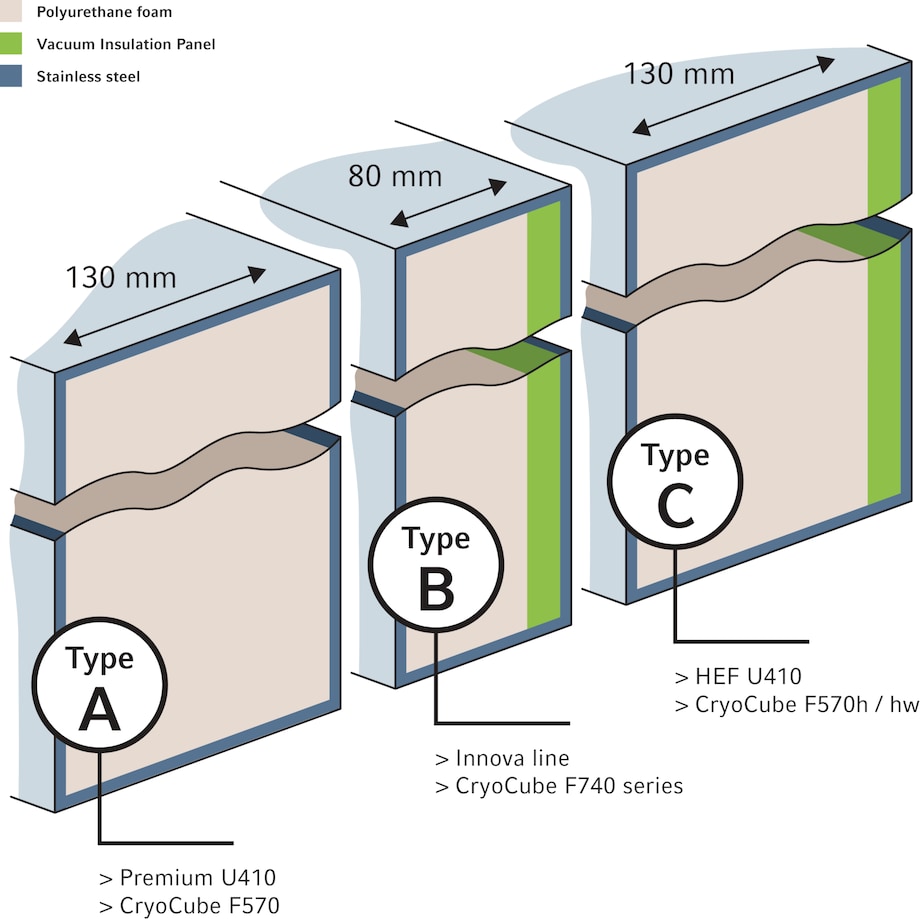

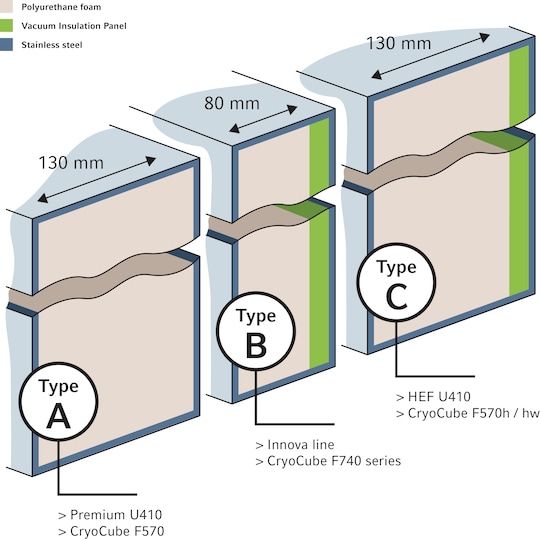

When it comes to maximizing sample storage capacity at the bench, the Eppendorf CryoCube F101h ULT freezer sets the standard: Up to 6,600 vessels below your bench in the lab with real -80 °C. By taking advantage of ultra-efficient, compact vacuum insulation panels which are used in combination with traditional PU foam insulation, we managed to slim down the freezer walls.

The Eppendorf CryoCube F101h offers a 2-compartment lay-out and two insulated inner doors for easy sample access and safe sample storage at -80 °C. The walls are 80 mm thick based on foam and vacuum insulation panels. The footprint is limited to half a square meter, especially designed for small labs. The temperature range for this -80 °C lab freezer is between -50 °C and -86 °C. The rails enable flexible positioning of the shelf, depending on your needs.

The ULT freezer has a volume of 101 L (3.6 cubic feet) and a temperature range from -50 °C to -86 °C. The CryoCube F101h is based on the freezer model:

CryoCube F101h:

• 80 mm wall (polyurethane insulation and vacuum insulation panels)

• "Green" hydrocarbon-based cooling liquids (R290/ R170)

• Air-cooling

Worried about your sample safety?

The most important aspect of long-term sample storage is safety. The CryoCube F101h freezer is equipped with reliable heavy-duty compressors (2-stage cascade cooling system). Quick pull-down times enable fast re-use after cleaning/defrosting of the instrument. The freezers have short recovery times after opening to provide extra sample safety (Door-Open-Recovery/DOR) when getting back to -80 °C. The temperature range of this ULT freezer is from -50 °C to -86 °C. Most users put the set point to -80 °C.

The automatic vent port enables fast re-access if needed.

For even higher sample safety, the ULT freezers can be equipped with CO2/LN2 back-up systems and a chart recorder. Temperature monitor systems can be used to monitor the freezers remotely.

Cost of ownership

When investing in a new ULT freezer, the product price itself is only one aspect. Others include the long-term costs of power consumption and the costs of service and spare parts. Keep in mind, a high-quality ULT freezer will do its job in the lab for 10 years or more.

Burdened by unsorted boxes cluttering your freezer?

Make your scientific life easier: Store your freezer boxes (also known as storage boxes) within organized metal freezer racks. The CryoCube F101h can be equipped with a broad range of different racks made of stainless steel as well as of aluminum. Take advantage of the online Eppendorf rack configuration tool (please use Mozilla FireFox as browser): Rack configuration tool

For other racking systems, please check the inner dimensions of the freezer and contact Eppendorf.

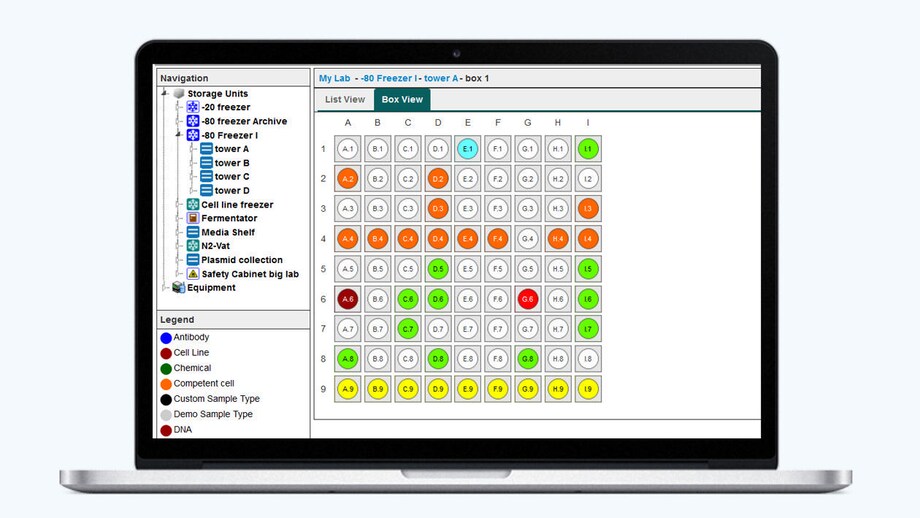

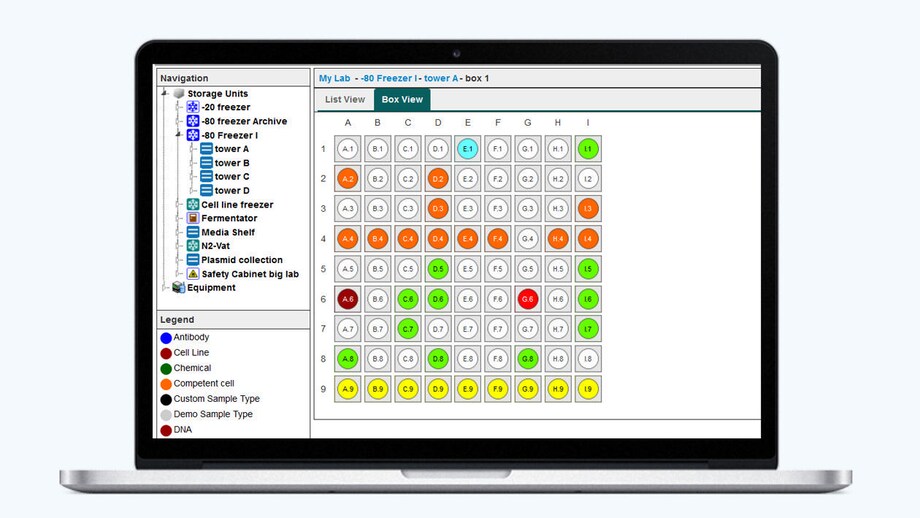

Additionally, you might think about a sample management solution beyond sample location documentation by paper or spreadsheet.

Start a 30-day free trial of our sample management software eLabInventory:

www.eLabInventory.com

Our part for sustainability

Eppendorf constantly validates and improves production processes for a better sustainability footprint. For our freezers, we address:

• Production moved into new building with state-of-the-art building insulation to save heating energy and power

• 100 % green, renewable power supply in the production factory

• Heat output during final individual unit testing discharges building heating system

• Plastic and cardboard compactors introduced and waste rebate system in place

• Local requirements for waste management (collection of electronic waste like circuit boards, recycling via authorized recycling organizations) and internal guidelines

• Experience in usage of green cooling liquids in Eppendorf ULT freezers for more than 15 years

• Packaging parts have increasing share of recycled origin, the cardboard is made of up to 70 % recycled material

• Packaging is more than 99 % recyclable (wood, cardboard, PE-foil)

• REACH + RoHS compliant

• ENERGY STAR® partner

• ACT/My Green Lab partner

• Marketing material is printed on certified paper, focus on pdf wherever possible

• Shipment of freezers by cargo ship to reduce CO2 footprint

Learn more about sustainability at Eppendorf

Which factors influence the sustainability of a freezer?

Sustainability for ULT freezers is a challenge: Maintaining extremely low temperatures of -80 °C or even -86 °C for 24 hours a day, 7 days a week requires energy.

The stored samples need to be safe: When the freezer door has been opened, you expect a fast recovery back to -80 °C. Efficient cooling requires energy as well as powerful compressor systems.

There are multiple factors influencing the energy consumption of a lab freezer for ultra-low temperatures:

• Thickness of insulation

• Type of insulation

• Type of cooling liquids

• Efficiency of compressors

• Control of compressor

• Pressure in cooling system

• Style of cooling loops (diameter, length, density, ...)

• Sealings of outer door

• Sealings of inner doors

• Insulation of inner doors

• Insulation of outer door

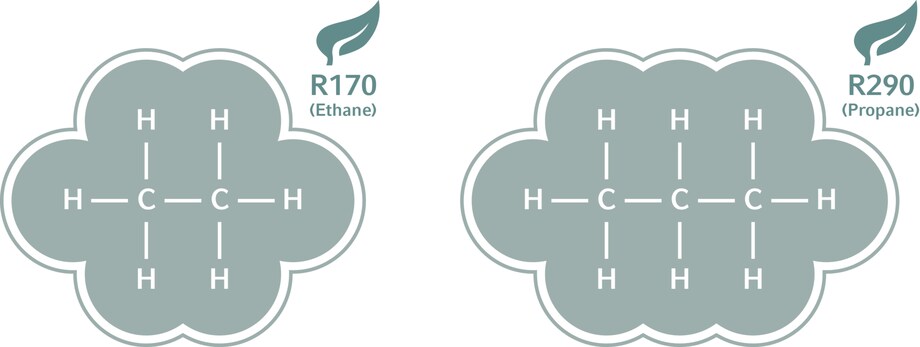

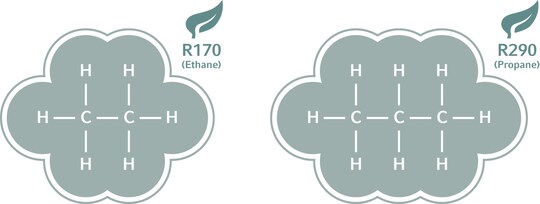

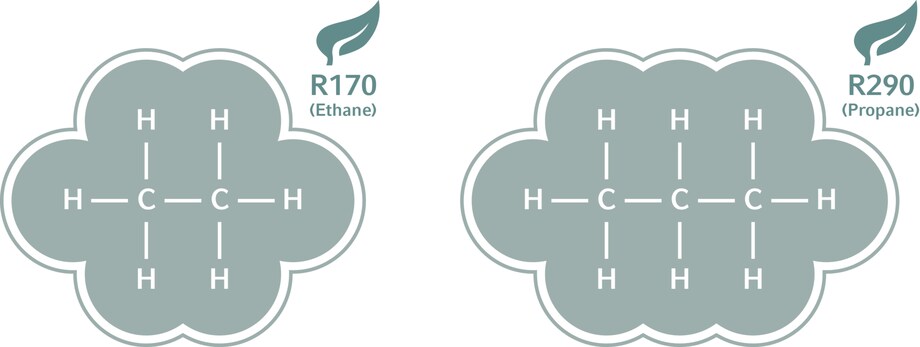

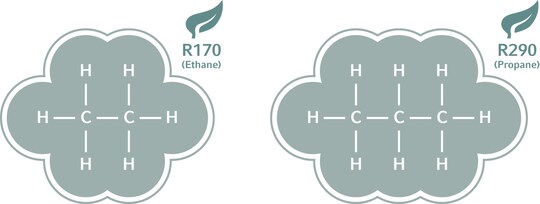

Hydrocarbons – green cooling of the future

In 2014, the European Union announced a ban of all non-hydrocarbon-liquids (EU_517/2014) until 2020 (also known as F-gas regulation). This ban includes all cooling devices except instruments for temperatures below -50 °C. Based on this exception, ULT freezers for -86 °C can continue to run with non-hydrocarbon cooling liquids like HFCs. However, it also makes sense to replace the HFC cooling liquids for ULTs as global warming needs to be slowed down.

Which cooling liquids can be used as a green alternative? Hydrocarbons are also known as green or natural gases. The two major representatives for cooling purposes are propane and ethane (known as R290 and R170).

Due to this goal, we at Eppendorf clearly plan to replace all classic cooling ULT freezers in our portfolio within the next years.

Read more in our WhitePaper about the regulations.

Remember 2008?

As one of the very first advocates of "green" hydrocarbon-based gases at -86 °C, Eppendorf now has more than 15 years of experience in R&D, production, logistics, and service in the field.

In 2008, the (Eppendorf) New Brunswick Premium U570h was one of the very first commercially available ULT freezers driven by green cooling liquids.

Safety assessment for green gases:

Based on IEC 60335-2-89, there are no additional required safety instructions for using natural gases in ULT freezers as long as the cooling liquid loops are hermetically sealed and the amount per cooling liquid is limited to 150 g. All Eppendorf ULT freezers using natural gases fulfill these conditions for safe usage.

Annoyed by uncomfortable handling?

Ergonomics goes far beyond the »ergonomically designed chair«. Eppendorf already started to optimize the ergonomics of laboratory devices in the early 1970s.

In 2003, we started the PhysioCare Concept, focusing on ergonomic liquid handling devices like our pipettes.

Nowadays, the Eppendorf PhysioCare Concept has been extended to include additional laboratory products as a holistic solution to harmonize the workflow in your laboratory with your health and well-being. Examples for the Eppendorf ULT freezer include:

• Intuitive interface for easy handling

• Vent port for easy re-access to samples

• Low noise level for convenient working conditions

• Ergonomic door handle for easy opening and closing

• All cable interfaces are located at one corner for convenient access

Further information about the Eppendorf PhysioCare Concept:

www.eppendorf.com/physiocare/

Sample identification needed?

Sorting samples in freezer boxes and freezer racks is the first level of improved storage efficiency. Correct and stable labeling is your next level: The SafeCode system provides prelabeled, barcoded vessels with 3-level coding in multiple formats to safeguard your samples and improve your processes.

TheEppendorf DataPort provides all relevant vessel information for complete documentation such as Certificate of Quality, lot number, drawings, and order number - all online.

Manage your barcoded samples with sample management software like eLabNext.

Lost in samples? Stay organized!

Over many years, you collect hundreds and thousands of samples – samples that are the results of years of hard work – samples of high value. When storing these in the ULT freezer at -80°C, it is vital to keep them safe and accessible.

Many scientists still use spreadsheets or even paper-based lists to keep track of their storage. While these solutions may work most of the time, they are susceptible to human error, damage, and misplacement.

Keep track of your samples with eLabInventory

eLabInventory is a sample management software.

Start a free 30-day trial!

Visit www.eLabInventory.com

Struggling with paper-based documentation?

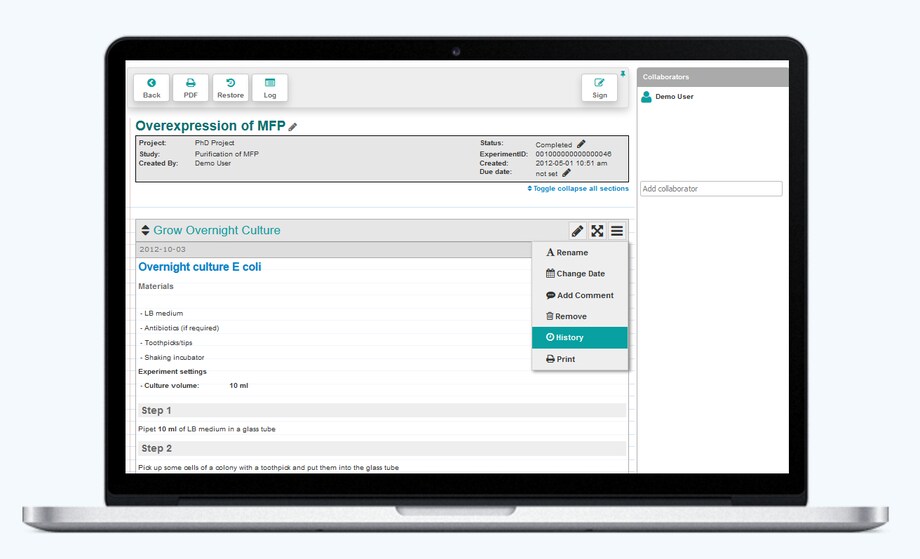

The eLabJournal Electronic Lab Notebook offers an intuitive and flexible solution to document research and track research data like workflow processes where the ULT freezer is involved. Improve efficiency when documenting, organizing, searching, and archiving collected data. With the free eLabJournal add-ons, you can extend the functionality of eLabJournal to a fully integrated Laboratory Information Management System.

Start a free 30-day trial!

Visit www.eLabJournal.com

Efficient lab and device management with VisioNize

®

Lab Suite

Are you interested in monitoring your lab devices and receiving notifications e.g., for device alarms? A digital, connected lab offers even more.

Gain access to a modular range of digital services and choose what works for your lab. VisioNize Lab Suite offers everything you need as a Lab Manager or scientist to get started to digitally manage your lab for increased sample security, compliance needs and maintenance management.

Chart your own course to digital lab excellence! Find out more

Pit stop needed?

Taking care of your freezer can help ensure optimal storage of your samples for years to come.

In addition to our extensive standard warranty, Eppendorf offers ULT Freezer Performance Plans to suit your lab’s needs while enhancing your peace of mind. You can choose between essential function checks, preventive maintenance plans, or Installation and Operational (IQ/OQ) certification services. Protect your priceless samples! Learn more.

End-of-Life

Disposal of packaging

The packaging of the ULT freezer contains different materials, this includes a wooden pallet, cardboard, a plastic dust cover, and some foam parts. Recycling of materials becomes more and more important every day: Are you aware that nearly all cardboard material is recycled in Europe? Our freezer packaging cardboard material consists of ca. 70% recycling material. Please support the global sustainability initiative of recycling valuable raw material by also collecting the freezer cardboard packaging material and disposing of it in the appropriate collection container at your organization. In respect to the plastic dust cover made of LD-PE and the foam parts, we recommend to select a dedicated recycling partner where PE material can be recycled. We suggest you contact your local waste hauler or facility management team to understand the available recycling options for your organization.

Disposal of instrument

Our freezers last for many years, but if they need to be replaced, we kindly ask you to fulfill local requirements for disposal of these instruments. We strongly recommend a certified local recycling partner with experience in instruments with active cooling. Keeping it “local“ reduces the impact of transportation, and the „certified“ aspect is recommended due to the safe and sustainable removal and recycling of the cooling liquids.

Decontamination

This piece of equipment was used in a laboratory and/ or was used to handle biological samples. Please keep in mind to adequately decontaminate the equipment which needs to be disposed. Check local requirements. For more information, get in contact with your local biosafety officer and/ or waste officer. Check if your local recycling partner has special instructions and/ or documentation requirements. You may also use the Eppendorf decontamination form sheet as guidance.

Read More

Read Less

Technical Data

| Specifications | CryoCube® F101h |

|---|

|

Box capacity per freezer |

|

| 53 mm (2 in) tall boxes | 66 |

| 64 mm (2.5 in) tall boxes | 48 |

| 76 mm (3 in) tall boxes | 36 |

| 89 mm (3.5 in) tall boxes | 24 |

| 102 mm (4 in) tall boxes | 24 |

| 127 mm (5 in) tall boxes | 24 |

|

Box capacity per rack |

|

| 53 mm (2 in) tall boxes | 10 |

| 64 mm (2.5 in) tall boxes | 8 |

| 76 mm (3 in) tall boxes | 6 |

| 89 mm (3.5 in) tall boxes | 4 |

| 102 mm (4 in) tall boxes | 4 |

| 127 mm (5 in) tall boxes | 4 |

| Cooling type | air cooling |

| Cooling liquid | green cooling liquids (R290 / R170) |

| Heat output | 196 W |

| Insulation | vacuum insulation paneling / polyurethane foam |

| Capacity | 101 L (3,6 ft³) |

| No. of compartments | 2 |

| No. of internal doors | 2 |

| Max. racks per freezer | 6 |

| Noise level | 39.7 dBA |

| High-Efficiency | yes |

| Power supply | 230 V, 50 Hz |

| Max. power consumption | 4700 W |

| Average Daily Consumption (230 V) | 4.7 kWh/day |

| Average Daily Consumption (115 V) | 5.1 kWh/day |

| Dimensions (W × D × H) | 93,6 × 62,9 × 83,4 cm / 36,9 × 24,8 × 32,8 in1)2)3) |

| Footprint (WxD) | 90 x 56.6 cm |

| Shipping weight | 153 kg / 337 lb |

| Product weight | 123 kg / 271 lb |

| Temperature range | -50 °C to -86 °C |

| Access port | 2 |

| Remote Device Monitoring and Notifications (VisioNize®) | VisioNize® box enabled |

| Pull-down time to -80 °C | 2h4) |

|

Included |

|

| CO2 backup system | no |

| LN2 backup system | no |

| Chart recorder | no |

1)Optional CO2/LN2 backup systems add 8.65 cm/3.5 in to height.

2)To allow for handles and hinges, add 80 mm to width of upright freezers and 110 mm to the depth of chest freezers.

3)Door open adds up to 15 cm.

4)Empty freezer with shelves fitted, upright freezers only, pull down from 21 – 23 °C ambient conditions.

Applications

- ULT freezers are suitable for storage and preservation of all types of biological materials/samples:

• Bacteria

• Cells

• Spores

• Pollens

• Protozoa

• Blood components (research only)

• DNA

• Tissue used in research only

• Preservation of chemicals or material testing components for a longer period of time

Features

- Vacuum insulation panels allow for increased internal capacity with the same footprint as traditionally foamed freezers

- Inner doors are gasketed as well as insulated creating 2 separate compartments minimizing cold air loss while you access your samples

- Easy-to-read LED control panel and alarm status

- Special vacuum vent with plunger ergonomically located to gain immediate access to your freezer

- Inner doors can be quickly removed without the need for tools for easier and faster defrosting

- Full stainless steel interior for easy cleaning during maintenance and defrost cycles; powder-coated steel exterior

- Special low-temperature outer door seals allow gaskets to remain flexible at –86 °C and prevent ice buildup for easy access to samples

- Password protection of alarm and temperature setpoints to prevent unauthorized setting changes