-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Medlab Middle East 2025

- Bioprocessing Summit Europe 2025

- Biologics World Nordics 2025

- SLAS International 2025

- BioProcess International Europe 2025

- ASIA LABEX: The Lab Show 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Medlab Middle East 2025

- Bioprocessing Summit Europe 2025

- Biologics World Nordics 2025

- SLAS International 2025

- BioProcess International Europe 2025

- ASIA LABEX: The Lab Show 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

You are about to leave this site.

Please be aware that your current cart is not saved yet and cannot be restored on the new site nor when you come back. If you want to save your cart please login in into your account.

Read more

Read less

Now we can start full speed ahead toward our goal of zero carbon emissions. We thank everyone in the Eppendorf Group who is working hard to achieve this goal together. Because only if everyone pulls together, the ambition of drastic cutting down the carbon emissions in our own operations by 2028 can become a reality.

Read more

Read less

„We will continue to look hard for ways to significantly reduce the remaining emissions as well.“

Enrico Jakobi

Head of Sustainability & HSE

Emissions

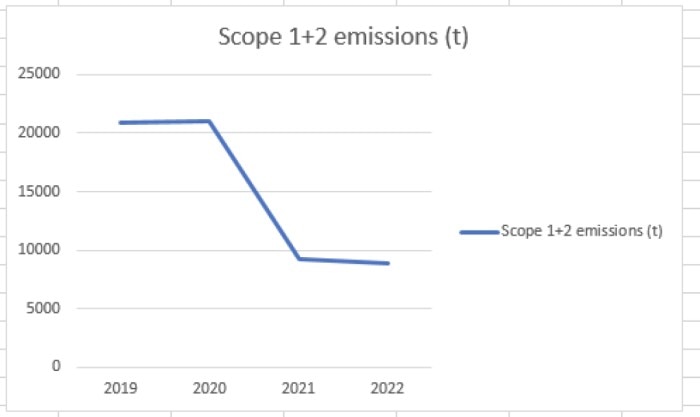

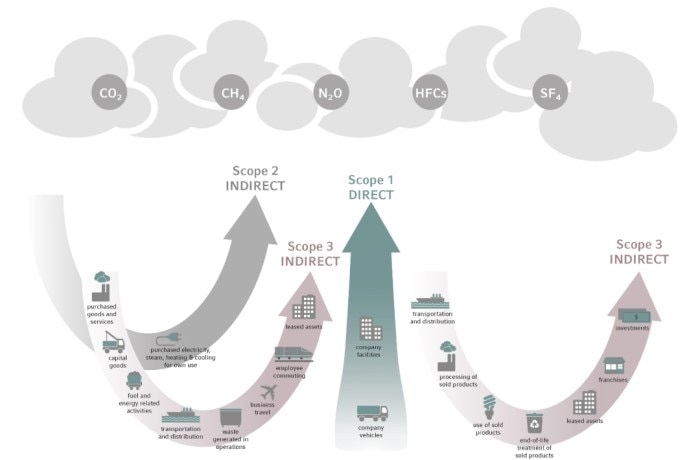

The greenhouse gas (GHG) emissions of companies are captured using the methodology of the Greenhouse Gas Protocol. With this approach, a company's GHG emissions are divided into three categories (scopes 1, 2, and 3). In 2022, Eppendorf already accounted for the GHG emissions of its

own organization (thus covering scopes 1 and 2) for the year 2019, resulting in a 58% reduction in emissions since then.

Scope 3 emissions are considerably more challenging to assess as they often lie beyond a company's direct operational control. Scope 3 emissions include upstream and downstream emissions generated by activities such as transportation, raw material usage, and especially the use of sold

products like a centrifuge or a freezer. These Scope 3 emissions typically account for over 90% of a company's total emissions in most cases. Eppendorf aims to comprehensively account for all GHG emissions in the future.

Zero Carbon Emissions

Eppendorf sets their goal: Cut our own emissions as a company down to zero by 2028 Eppendorf faces up to its responsibility and has clearly mapped the core issue of sustainability in its corporate strategy. To achieve this goal, the Sustainability & HSE team has developed a climate strategy. As part of the overarching Eppendorf sustainability strategy, this concept specifies concrete measures that significantly reduce CO2 emissions. The team developed and coordinated all actions in interviews and workshops with experts and departments.

Read more

Read less

What are our steps to reach this ambitious target?

- Switch to renewable energy sources at all Eppendorf sites worldwide. We are already using 100% CO2-neutral green electricity at most of our production facilities and in the global headquarters. As a result, CO2 emissions in 2021 were reduced by 57% compared to the previous year.

- High climate standards for new buildings are to be established. The aim is to achieve the so-called DGNB (Deutsche Gesellschaft für Nachhaltiges Bauen) platinum certification, the highest award for sustainable construction for all building developments in Germany.

- Optimizing the energy efficiency of buildings should help to consume less resources.

- By further reducing air freight, transport goods are to be shifted more to rail and sea, resulting in less CO2.

- To gain a low-CO2 vehicle fleet, the entire corporate vehicle fleet will be electrified.

- Environmentally friendly travel will be promoted more strongly.

- We want to benefit more than before from "swarm knowledge" through systematic knowledge development and transfer.

- A competition for climate projects will reward particularly exceptional climate projects.

Carbon emissions scopes

Scope 1: Direct GHG emissions refer to emissions from sources that are

owned or controlled by the company, like the generation of electricity, heat

or steam, transportation of materials, products, employees by company

owned vehicles and to fugitive emissions.

Scope 2: Indirect emissions refer to purchased electricity.

Scope 3: All other indirect GHG emissions which occur in a company’s

value chain, like extraction and production of purchased materials, product

use, disposal of waste, or employee business travel.