MENU

CN | CNY

CN | CNY

-

- All Centrifuges

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Sample and Information Management

- GLP Products China

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Pipette Tips

- Bottle-Top Dispensers

- Pipette Controllers

- Dispenser & Pipette Accessories

- Automated Pipetting

- Automation Consumables

- Automation Accessories

- Liquid Handler & Pipette Services

Sorry, we couldn't find anything on our website containing your search term.

Sorry, we couldn't find anything on our website containing your search term.

- Home

- Products

- Centrifugation

- Ultracentrifuges

- Centrifuge CC40 Series

Centrifuge CC40 Series

Product Information

Scale up your separation with the Centrifuge CC40 Series. Increase the efficiency and quality of production. No more meddling with splitting samples into smaller batches since all can be purified in one go decreasing handling time and the potential risk of cross contaminations. The system is perfect for the purification of high-quality viral and nanoparticles using either density gradient centrifugation or precipitation. Choose Centrifuge CC40NX for large scale production. In addition we offer Centrifuge CC40SNX for pilot and smaller research and development settings.You will find additional download material at the bottom of this page

Single Devices (2)

2 Single Devices

Catalog no.

5725000405

|

Catalog no.

5725010401

|

Show more Products

Added to Your Cart

Product Information

Technical Data

Features

Product Information

Let our experts configure, determine the perfect settings, install, and qualify your system to your specific needs. No more need for additional components- get the most out of a single system with induction motor and integrated cooling system . Furthermore, our systems and service offerings to fully support customers with GMP requirements making it the choice for vaccine manufacturers. Data-management is made simpler than ever with the on-board logging and additional service offerings.

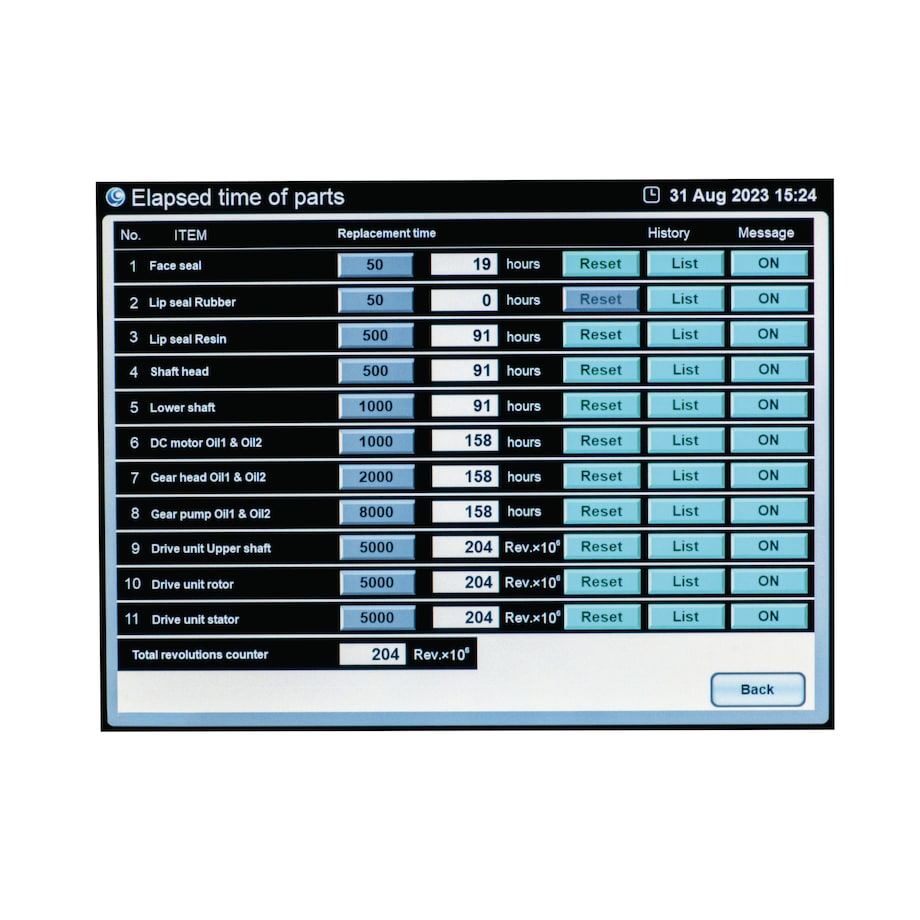

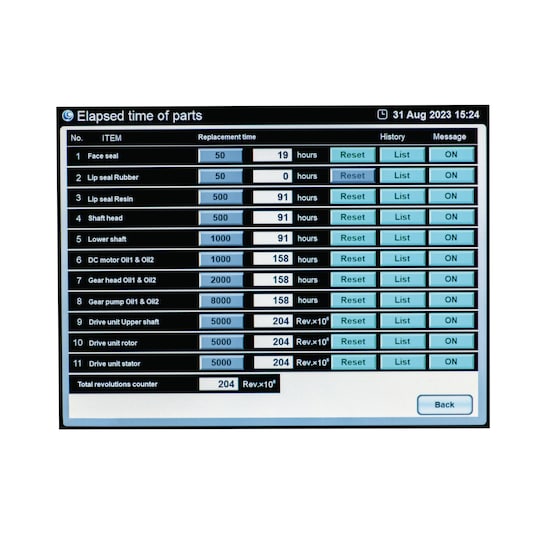

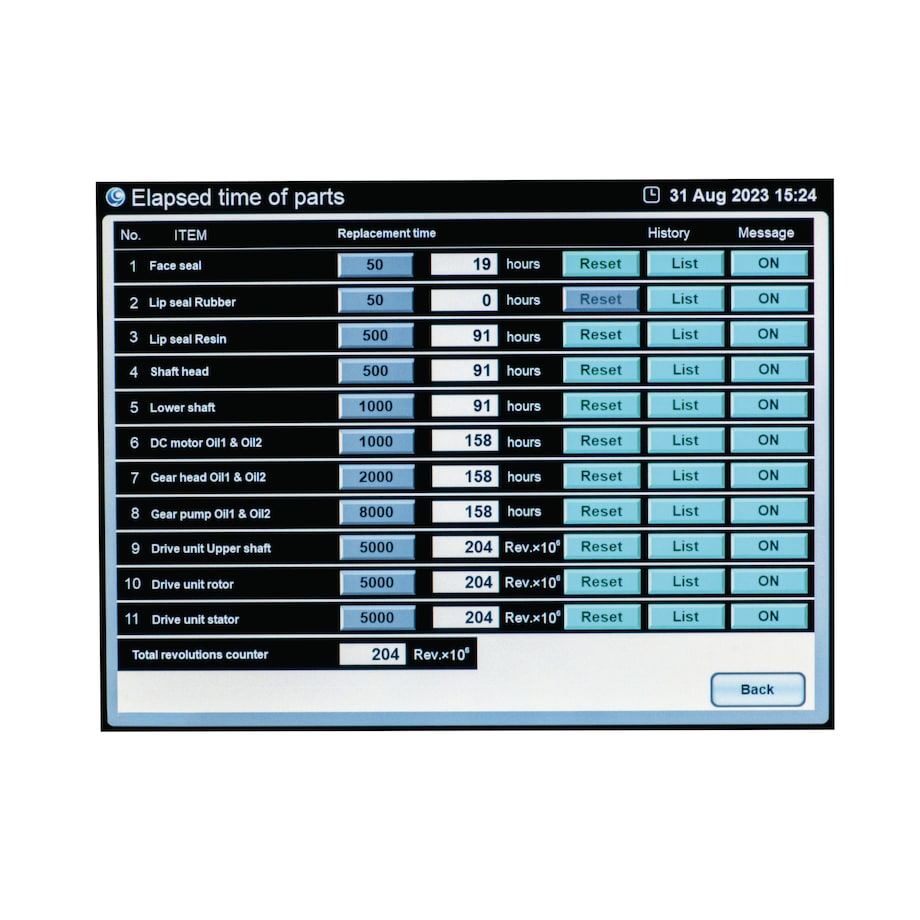

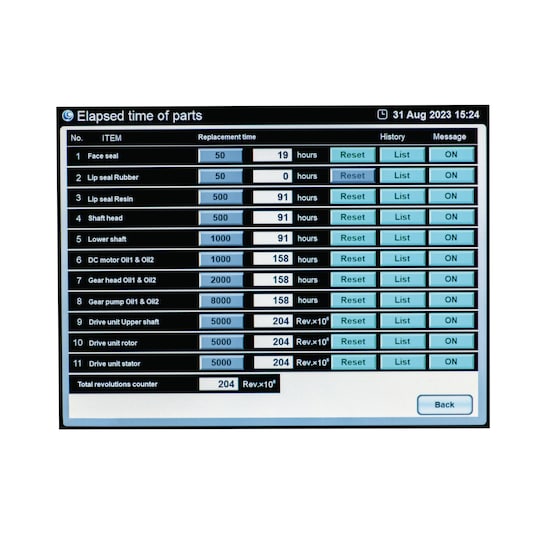

Always perfect perfomance

The software automatically monitors the time critical components that need to be changed regularly. Once the end of the recommended lifetime is reached the software will give a warning so the components can be exchanged and the system remains operating in perfect condition.

The software automatically monitors the time critical components that need to be changed regularly. Once the end of the recommended lifetime is reached the software will give a warning so the components can be exchanged and the system remains operating in perfect condition.

Optimized system design to save space and reduce noise

The centrifuge is equipped with an induction motor with integrated cooling system. This reduces the operating sound below 68 dB and eliminates the need for additional componets like air compressors.

The centrifuge is equipped with an induction motor with integrated cooling system. This reduces the operating sound below 68 dB and eliminates the need for additional componets like air compressors.

Titanium cores available for optimized operation

For more convenient assembly of rotors and cores and reduced acceleration and deceleration times we offer especially designed and light-weight titanium cores. They are also heat- and chemical-resistant making the device compatible with SIP and CIP treatments.

For more convenient assembly of rotors and cores and reduced acceleration and deceleration times we offer especially designed and light-weight titanium cores. They are also heat- and chemical-resistant making the device compatible with SIP and CIP treatments.

Your lab instruments in perfect order and qualified with Eppendorf Services

We are committed to providing reliable services and tools at your location. This includes a comprehensive range of carefully designed service solutions performed by our dedicated manufacturer-trained and certified Technical Service teams.

We are committed to providing reliable services and tools at your location. This includes a comprehensive range of carefully designed service solutions performed by our dedicated manufacturer-trained and certified Technical Service teams.

Added security through specialy designed power switch

The device comes with a breaker that can be secured in the OFF position via a padlock. An extra emergency switch is available to stop the device immediately.

The device comes with a breaker that can be secured in the OFF position via a padlock. An extra emergency switch is available to stop the device immediately.

More easy lifting

A hydraulic lift control is available for lifting the rotor assembly out of the chamber. The control is designed with security in mind and will only operate if the vacuum has been released, the door is not locked and the motor is not engaged.

A hydraulic lift control is available for lifting the rotor assembly out of the chamber. The control is designed with security in mind and will only operate if the vacuum has been released, the door is not locked and the motor is not engaged.

Thoughtful accessories with each device

Includes tools to facilitate replacement of parts.

Includes tools to facilitate replacement of parts.

Holistic solution with accessories

Together with the the sample tank, sample feed system, rotor cart, and Automatic Fraction Dispenser, Centrifuge CC40NX offers a solution to all customers from loading to the refinement of the samples.

Together with the the sample tank, sample feed system, rotor cart, and Automatic Fraction Dispenser, Centrifuge CC40NX offers a solution to all customers from loading to the refinement of the samples.

Read More

Read Less

Technical Data

| Specifications | Centrifuge CC40NX | Centrifuge CC40SNX |

|---|

| Max. RCF | − | − |

| Speed | 1000 – 40000 rpm (100 rpm steps) | 1000 – 40000 rpm (100 rpm steps) |

| Max. capacity | 8L for batch processing and 7.7L for continious flow processing | 1.6L for continous flow processes |

| Timer | from 1 min to 99 h 59 min (with 1 min increments) with HOLD function | from 1 min to 99 h 59 min (with 1 min increments) with HOLD function |

| Interfaces | Color touch-sensitive LCD | Color touch-sensitive LCD |

| Power supply | 200 – 240 V, 50/60 Hz | 200 – 240 V, 50/60 Hz |

| Dimensions (W × D × H) | 1,750 × 1,150 × 2,950 mm | 1,750 × 1,150 × 2,160 mm |

| Product weight | 900 kg | 770 kg |

| Drive unit | Induction motor (direct drive) | Induction motor (direct drive) |

| Vacuum system | Oil rotary vacuum pump | Oil rotary vacuum pump |

Features

- Separate nanoparticles with speeds up to 118,000 x g (40,000 rpm)

- Customize the system to suit your throughput need up to 7.7 L maximum capacity in continuous-flow operation, and 8.0 L maximum in batch operation with Centrifuge CC40NX

- Protect your sample from contamination with a reliable sealing pressure difference design

- Supports customers with GMP requirements

- Compatible with sterilization via CIP/SIP treatment

- Benefit from extensive services including factory acceptance tests, installation, site acceptance tests, IQ/OQ , application support and user trainings

- Light-weight and easy-to-handle titanium core

- Reduce expenses for additional devices and utilities as well as space requirements with the integrated induction motor with cooling system

Downloads: Centrifuge CC40 Series

-

English