MENU

AU | AUD

AU | AUD

-

- All Centrifuges

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Pipette Tips

- Bottle-Top Dispensers

- Pipette Controllers

- Dispenser & Pipette Accessories

- Automated Pipetting

- Automation Consumables

- Automation Accessories

- Liquid Handler & Pipette Services

Sorry, we couldn't find anything on our website containing your search term.

Sorry, we couldn't find anything on our website containing your search term.

- Home

- Products

- Bioprocess

- Bioprocess Software

- DASware® control

DASware® control

DASware control single

DASware control

• Advanced process monitoring, control, and data logging - for parallel cultivation with individual control of each bioreactor

• Advanced process monitoring, control, and data logging - for parallel cultivation with individual control of each bioreactor

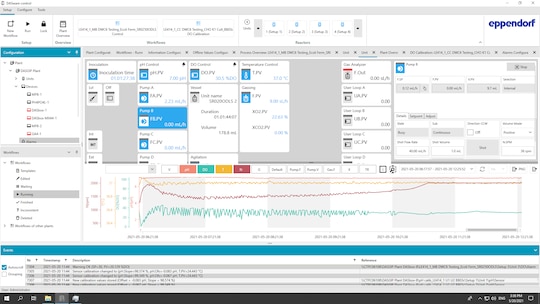

Product Information

DASware control is the bioprocess SCADA software at the heart of all Eppendorf small and bench-scale bioreactor systems and our large- scale single-use system. It enables individual monitoring and control of up to 24 bioreactors in parallel, process automation, and advanced data analysis, providing maximum performance from experimental design to result.You will find additional download material at the bottom of this page

Products (5)

Accessories (1)

5 Products

|

|

|

|

|

|

Catalog no.

78600189

|

Catalog no.

76DGCS4

|

Show more Products

Added to Your Cart

Product Information

Features

Product Information

Bioreactor Systems and Software Solutions – Orchestrated for Bioprocess Control, Automation, and Analysis

DASware control is the central bioprocess software solution from Eppendorf. Beyond bioprocess monitoring and control, it enables the seamless integration of bioprocess systems, control software, data analysis tools, and automation solutions to form a complete upstream bioprocessing solution.

Key benefits

• Parallel process monitoring and control.

• Reduced complexity due to the use of one central software solution.

• Easy integration of devices such as third-party sensors.

• Simplified data sharing and improved data analysis through seamless connection to BioNsight® cloud software.

Compatible controllers

• Bioprocess control software for the DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems.

• Optional SCADA software for SciVario® twin, BioFlo® 120, BioFlo 320, and BioFlo 720 bioprocess controllers that offers advanced features for process control, such as the integration of external sensors and scripting of feedback loops.

• Enables seamless integration of selected controllers with the Bioprocess Autosampler.

DASware control is the central bioprocess software solution from Eppendorf. Beyond bioprocess monitoring and control, it enables the seamless integration of bioprocess systems, control software, data analysis tools, and automation solutions to form a complete upstream bioprocessing solution.

Key benefits

• Parallel process monitoring and control.

• Reduced complexity due to the use of one central software solution.

• Easy integration of devices such as third-party sensors.

• Simplified data sharing and improved data analysis through seamless connection to BioNsight® cloud software.

Compatible controllers

• Bioprocess control software for the DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems.

• Optional SCADA software for SciVario® twin, BioFlo® 120, BioFlo 320, and BioFlo 720 bioprocess controllers that offers advanced features for process control, such as the integration of external sensors and scripting of feedback loops.

• Enables seamless integration of selected controllers with the Bioprocess Autosampler.

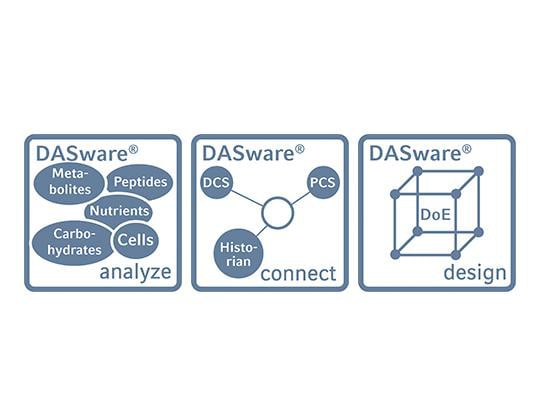

Expand your capabilities with the DASware software suite

DASware design, analyze, and connect are optional add ons to the DASware control SCADA software.

• Application of the Design of Experiments (DoE) concept via a full factorial DoE builder or by importing DoE designs from third-party DoE tools.

• Seamless integration of external lab devices to the bioreactor for process automation and feedback control loops.

• Integration into process control systems and legacy corporate historians for company-wide access to all relevant bioprocess data.

Your data is simply there

Bioprocess data can be seamlessly transferred from DASware control to BioNsight cloud software.

• Enables for remote monitoring and analytics.

• Enables data contextualization across devices, runs, and sites.

• Data preparation for AI-based analysis.

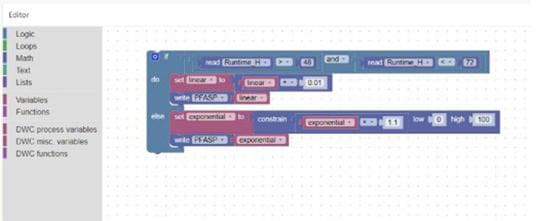

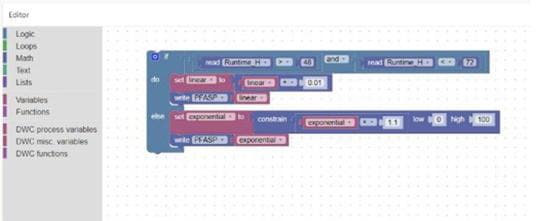

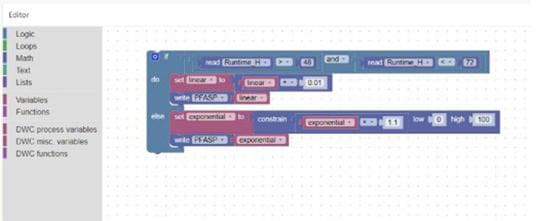

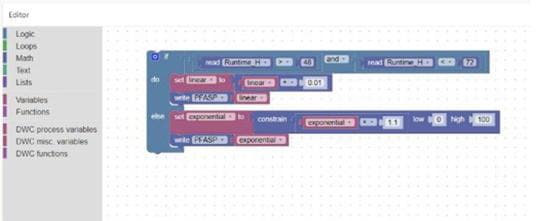

Easily customize your process control with graphical programming

• Ease of use: drag-and-drop interface allows users to create and modify workflows by linking functional blocks visually, reducing complexity compared to traditional scripting or coding.

• Improved accuracy: visual workflows help users spot logical or sequencing errors early, minimizing process disruptions and improving overall accuracy.

• Enhanced accessibility: users can quickly learn and deploy workflows, increasing operational efficiency and responsiveness to process changes.

• Transparency: Automatic logging of all changes supports compliance, while revision histories allow for easy audits.

Read More

Read Less

Features

- Parallel process control with individual control of each vessel: DASbox Mini Bioreactor System: up to 24 vessels, DASGIP Parallel Bioreactor Systems: up to 16

- Seamless integration with SciVario twin and BioFlo systems (up to 8 controllers), as well as BioFlo 720 (1 controller)

- Integrated batch functionality for process and recipe management

- Ideally suited for Design of Experiments (DoE)

- Parallel calibration and cleaning procedures

- Customized views and user-defined functions

- Automated data export, reporting and chart creation for Microsoft® Excel®

- Professional database with managed access (Postgre SQL Server)

- OPC communication for easy integration with third party-equipment using DASware connect and DASware analyze

- Integrated analysis of offline values, online calculated values, and alarm notification

- IQ/OQ package available