MENU

CZ | CZK

CZ | CZK

No results found

Search Suggestions

The Heat Is On! Temperature Verification for Your PCR Cycler

Lab Academy

- Molecular Biology

- Lab Life

- Safety & Biosafety

- Lab Routine

- Efficiency

- Amplification & PCR

- Quality

- Reproducibility

- Accuracy

- Essay

Why and how you should perform temperature verification

Just as in the human body, the temperatures of a PCR cycler fulfill a specific role. In fact, they must be precise because deviations affect amplification. This is why you should verify your cycler’s temperature on a regular basis to ensure that its performance remains within specifications, with no unwanted temperature deviations. Let us show you why this is important – and how to perform temperature verification easily!

Achieving stable and reproducible results with PCR is always a challenge. Many factors influence PCR, including setup, components, reaction vessels, environmental changes and the technical parameters of a PCR cycler. In this context, the performance of the thermoblock plays a major role in obtaining accurate and reproducible results.

First, the temperature of the thermoblock is critical for successful PCR! Exact adherence to defined temperatures is a prerequisite for reproducible PCR results. Deviations from the set point can lead to impaired denaturation efficiency, mispriming in the annealing phase or compromised polymerase activity during elongation. This is why your thermal cycler should provide a high level of temperature accuracy and homogeneity in all block positions. An inaccurate or inhomogeneous temperature profile, in contrast, can manifest itself in artificial PCR products, low or no product, or varying results within one microtiter plate. This is what happens when the Peltier elements responsible for heating and cooling do not heat properly – or even fail. The problem is most noticeable in microtiter plates (when entire sectors of wells are affected) but it can also happen in individual samples, where it is harder to spot.

Second, did you know that cyclers made by different manufacturers may differ when it comes to temperature control? Owing to these discrepancies, a PCR system that has been set up and optimized on one thermal cycler may not deliver a comparable PCR product with a cycler by a different manufacturer, even if you use the same PCR program.

When should you think about verifying your PCR cycler’s temperature? When the following conditions apply: You are concerned about reliable and reproducible results over an extended time. You care about your instrument and want to maintain its quality and reliability to ensure a long service life. You need confirmation that environmental changes are not affecting the quality of your results, or you work in a regulated environment such as pharma, in which preventive maintenance with instrument qualification is part of your daily quality control. And there’s another reason: When you use different cyclers for the same protocol, a comparison of temperature verification results from different cyclers gives you clarity before a PCR run – or may explain differences in the results.

Regular temperature verification of selected well positions and, if necessary, an adjustment of the thermoblock temperature ensure your thermal cycler is operating consistently, accurately and within manufacturer specifications.

What are your verification options? Sequential temperature verification measures one well at a time with a single-channel measuring tool. Parallel temperature verification, which is faster, measures the temperatures of multiple wells (e.g. at six positions) simultaneously with a multi-channel measuring tool. And of course, a prerequisite for temperature verification is preventive maintenance according to the manufacturer’s specifications.

Yearly full-service maintenance for your PCR cycler is recommended to ensure its performance, but testing the temperature of the block at shorter intervals can be useful for routine workflows. Things to consider when you test the block yourself:

You can use the Eppendorf Temperature Verification System T6 for routine checks between regular services. Just place a sensor in the thermoblock, connect it to the measurement unit, and start sequential or parallel temperature verification by using standard settings or your desired protocol. Afterward, export the report and the certificate – and you’re done!

Achieving stable and reproducible results with PCR is always a challenge. Many factors influence PCR, including setup, components, reaction vessels, environmental changes and the technical parameters of a PCR cycler. In this context, the performance of the thermoblock plays a major role in obtaining accurate and reproducible results.

Zero tolerance for deviations: Why the correct temperature matters

First, the temperature of the thermoblock is critical for successful PCR! Exact adherence to defined temperatures is a prerequisite for reproducible PCR results. Deviations from the set point can lead to impaired denaturation efficiency, mispriming in the annealing phase or compromised polymerase activity during elongation. This is why your thermal cycler should provide a high level of temperature accuracy and homogeneity in all block positions. An inaccurate or inhomogeneous temperature profile, in contrast, can manifest itself in artificial PCR products, low or no product, or varying results within one microtiter plate. This is what happens when the Peltier elements responsible for heating and cooling do not heat properly – or even fail. The problem is most noticeable in microtiter plates (when entire sectors of wells are affected) but it can also happen in individual samples, where it is harder to spot.

Second, did you know that cyclers made by different manufacturers may differ when it comes to temperature control? Owing to these discrepancies, a PCR system that has been set up and optimized on one thermal cycler may not deliver a comparable PCR product with a cycler by a different manufacturer, even if you use the same PCR program.

Be on the safe side: Temperature verification

When should you think about verifying your PCR cycler’s temperature? When the following conditions apply: You are concerned about reliable and reproducible results over an extended time. You care about your instrument and want to maintain its quality and reliability to ensure a long service life. You need confirmation that environmental changes are not affecting the quality of your results, or you work in a regulated environment such as pharma, in which preventive maintenance with instrument qualification is part of your daily quality control. And there’s another reason: When you use different cyclers for the same protocol, a comparison of temperature verification results from different cyclers gives you clarity before a PCR run – or may explain differences in the results.

Regular temperature verification of selected well positions and, if necessary, an adjustment of the thermoblock temperature ensure your thermal cycler is operating consistently, accurately and within manufacturer specifications.

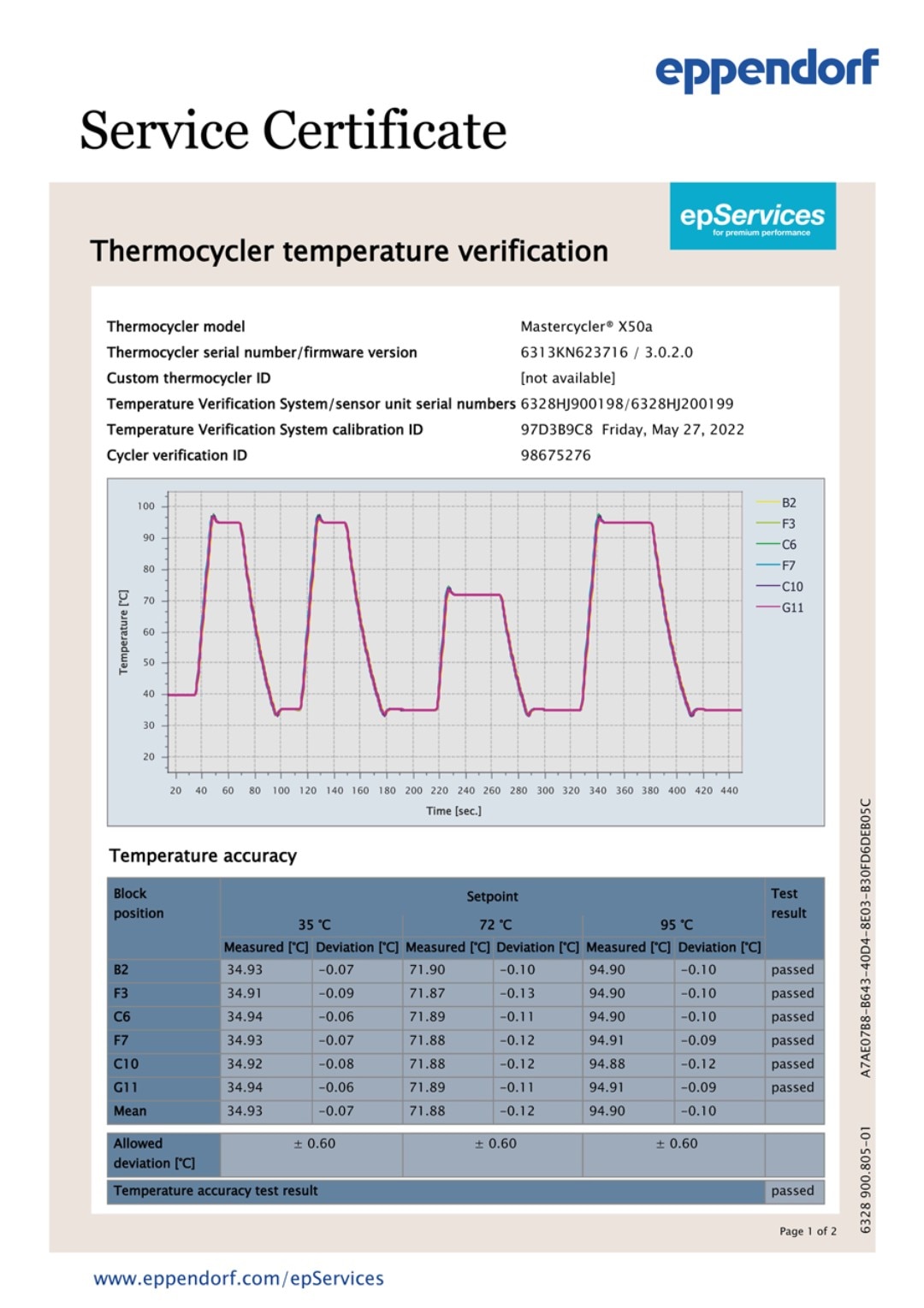

What are your verification options? Sequential temperature verification measures one well at a time with a single-channel measuring tool. Parallel temperature verification, which is faster, measures the temperatures of multiple wells (e.g. at six positions) simultaneously with a multi-channel measuring tool. And of course, a prerequisite for temperature verification is preventive maintenance according to the manufacturer’s specifications.

Do-it-yourself temperature verification

Yearly full-service maintenance for your PCR cycler is recommended to ensure its performance, but testing the temperature of the block at shorter intervals can be useful for routine workflows. Things to consider when you test the block yourself:

- Use the right sensors for your thermoblock well type – and make sure they fit perfectly.

- Make sure your temperature verification procedure meets all documentation and detection requirements in the laboratory according to national and international standards, e.g., NIST® (U.S.), PTB (Germany), UKAS/NPL (UK) or your desired country.

- Adjust the temperature if the temperature verification thresholds are exceeded, then verify the results again.

You can use the Eppendorf Temperature Verification System T6 for routine checks between regular services. Just place a sensor in the thermoblock, connect it to the measurement unit, and start sequential or parallel temperature verification by using standard settings or your desired protocol. Afterward, export the report and the certificate – and you’re done!

Read more

Read less

Figure 1: Temperature Verifications System T6 from Eppendorf for optional routine checks between regular services.

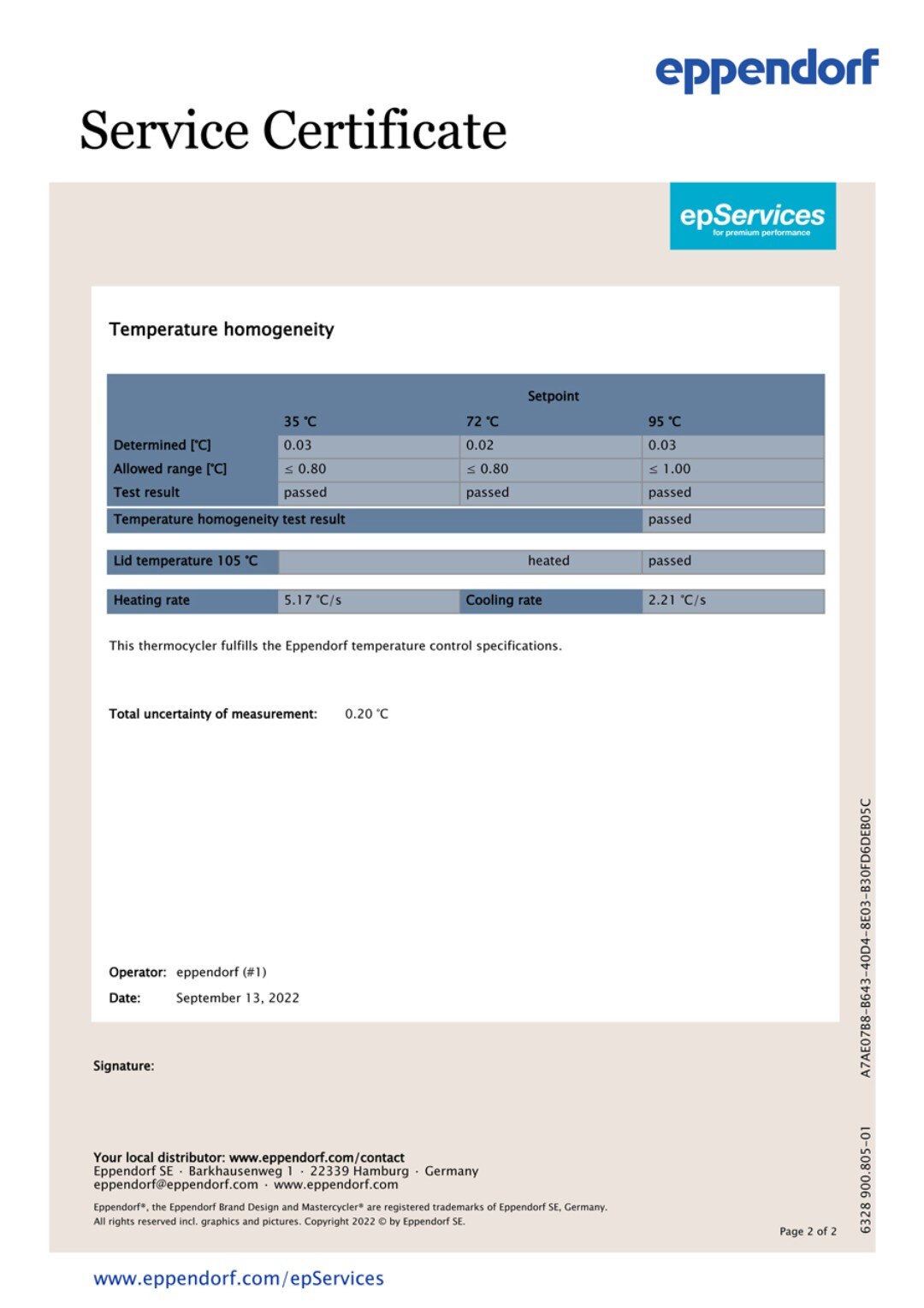

Let us do the job: Qualified full-service by Eppendorf

Reduce your administrative and operative workload and ensure premium cycler performance by outsourcing maintenance and verification to Eppendorf. The services from Eppendorf include temperature verification and the qualification of other relevant instrument parameters for complete system performance verification.

Read more

Read less

- Full flexibility: on-site or in-house services by our global service network

- Highest confidence in results: exclusively performed by certified Eppendorf specialists using certified test procedures and equipment

- Confidence in audits with regulatory compliance supporting documents: IQ/OQ service documents with detailed statistical analysis data support to be compliant with national and international standards, regulations and guidelines with relevant parts of EudraLex - Volume 4 - Good Manufacturing Practice (GMP) guidelines and 21 CFR Part 211

- Risk reduction: lowered risk of system failures and unexpected downtime

- We also verify other Eppendorf devices!

Check out the qualification services for all Eppendorf devices.

Read more

Read less