MENU

HK | HKD

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

HK | HKD

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

Sorry, we couldn't find anything on our website containing your search term.

In Harmony with Nature

Beyond Science

- Sustainability

- Lab Life

- Off the Bench

- Off the Bench

- Inspiring Science

New building materials may open up a future in which buildings and their environments can interact with one another. Whether organic or inorganic – materials will no longer be able to be assigned to distinct categories.

The building industry is considered to be one of the most resource-intensive sectors overall. Globally, it consumes roughly 36 percent of all available energy, and is responsible for 40 percent of all CO2 emissions. Innovations can contribute significantly – to the buildings themselves as well as in entirely new ways to the economy, to life and to the work which are all directly connected to these buildings. The central question: how can we meet the challenges of dwindling resources in times of a growing world population, climate change and a decline in biodiversity? Changes are necessary – we need to move away from fossil fuel-based resources and instead move towards sustainable, bio-based building strategies. New connections between the economy, technology and art offer reasons for hope.

The environment as a role model

American-Israeli professor Neri Oxman, for example, combines technology and biology in the Media Lab at the Massachusetts Institute of Technology (MIT). Together with an interdisciplinary team, she researches novel combination options for computer designs, digital manufacturing and materials science. Her goals: designs that comply with the principles of ecological sustainability to the maximum extent possible. For this purpose, she observes natural systems and processes in detail, allowing her to draw conclusions which will inform the development of new materials and styles. In 2020, the Museum of Modern Art (MoMA) in New York dedicated an entire exhibit to Oxman’s idea of “Material Ecology”. In a MoMA YouTube post on the occasion of the opening of the exhibit, Oxman explains the term as a “unique combination of research approach and designer philosophy, intended to bring the designed objects and their environment as closely together as possible.”

The environment as a role model

American-Israeli professor Neri Oxman, for example, combines technology and biology in the Media Lab at the Massachusetts Institute of Technology (MIT). Together with an interdisciplinary team, she researches novel combination options for computer designs, digital manufacturing and materials science. Her goals: designs that comply with the principles of ecological sustainability to the maximum extent possible. For this purpose, she observes natural systems and processes in detail, allowing her to draw conclusions which will inform the development of new materials and styles. In 2020, the Museum of Modern Art (MoMA) in New York dedicated an entire exhibit to Oxman’s idea of “Material Ecology”. In a MoMA YouTube post on the occasion of the opening of the exhibit, Oxman explains the term as a “unique combination of research approach and designer philosophy, intended to bring the designed objects and their environment as closely together as possible.”

Read more

Read less

Image source: The Mediated Matter Group

Silkworm colleagues

The results of a possible interaction and collaboration between humans and their environment are groundbreaking. Like a supernatural being, the several meter high, fine white fabric, which had previously been on display at the MoMA, oscillates from the ceiling. For the project “Silk Pavilion II”, Oxman left construction management to 17,532 silkworms. “We had observed that silkworms will spin their cocoons in a flat shape if they are unable to find tree branches by which to orient themselves”, explained Oxman in the streamed Q&A format. With the help of a metal scaffold, she merely provided the framework – the remainder of the work was carried out by self-motivated larvae. The thus constructed building made from silk fibers is breathable and extremely robust, as well as tearproof and long-lived, despite its delicate appearance.

For Oxman, the project also illuminates different dimensions: “Our relationships with other species are just as much a topic as our love for silk. We should ask ourselves the basic question of whether designers must always determine form”, says Oxman in her MoMA interview. In this context, she compares her role to the collaboration with an orchestra: “We begin as composers, and then we become conductors.” Additional advantages: for the construction of the pavilion, not a single larva needed to be scalded or otherwise killed, as is common practice in traditional silk production.

The results of a possible interaction and collaboration between humans and their environment are groundbreaking. Like a supernatural being, the several meter high, fine white fabric, which had previously been on display at the MoMA, oscillates from the ceiling. For the project “Silk Pavilion II”, Oxman left construction management to 17,532 silkworms. “We had observed that silkworms will spin their cocoons in a flat shape if they are unable to find tree branches by which to orient themselves”, explained Oxman in the streamed Q&A format. With the help of a metal scaffold, she merely provided the framework – the remainder of the work was carried out by self-motivated larvae. The thus constructed building made from silk fibers is breathable and extremely robust, as well as tearproof and long-lived, despite its delicate appearance.

For Oxman, the project also illuminates different dimensions: “Our relationships with other species are just as much a topic as our love for silk. We should ask ourselves the basic question of whether designers must always determine form”, says Oxman in her MoMA interview. In this context, she compares her role to the collaboration with an orchestra: “We begin as composers, and then we become conductors.” Additional advantages: for the construction of the pavilion, not a single larva needed to be scalded or otherwise killed, as is common practice in traditional silk production.

Read more

Read less

Image source: The Mediated Matter Group

Buildings out of a 3D printer

Oxman also experiments with 3D printers that she developed herself. In 2017, using a digital construction platform and an automated building system that analyzes environmental data which thus guides production, she and her team succeeded in building – i.e., printing – an open cupola 14.6 meters in diameter and 3.7 meters high in roughly 13.5 hours. A laser-equipped robot arm controlled the material-foam nozzle. Empty spaces between the walls, which were built in layers, were filled with cement. The team had previously tested a number of different fast-curing polyurethane foams.

“Aquahoja” – this is what Oxman calls the resin-bound cellulose fibers and polymer variants she developed as alternatives to traditional plastic. These compounds, which consist of organic, water-based materials, degrade over time and may therefore be utilized in a continuous cycle.

Accepting change

Oxman and her team understand change as a natural process that humans should not resist. After all, most natural units such as glaciers, plankton or dandelions adapt to and co-evolve with new conditions.

“Humans do not behave in this way; most resist change and stand in its way. By doing so, they create consequences for all species”, clarified MoMa curator Paula Antonelli in her contribution on YouTube. Oxman: “Nature does it best”. Why not copy as much as possible from it?

Oxman also experiments with 3D printers that she developed herself. In 2017, using a digital construction platform and an automated building system that analyzes environmental data which thus guides production, she and her team succeeded in building – i.e., printing – an open cupola 14.6 meters in diameter and 3.7 meters high in roughly 13.5 hours. A laser-equipped robot arm controlled the material-foam nozzle. Empty spaces between the walls, which were built in layers, were filled with cement. The team had previously tested a number of different fast-curing polyurethane foams.

“Aquahoja” – this is what Oxman calls the resin-bound cellulose fibers and polymer variants she developed as alternatives to traditional plastic. These compounds, which consist of organic, water-based materials, degrade over time and may therefore be utilized in a continuous cycle.

Accepting change

Oxman and her team understand change as a natural process that humans should not resist. After all, most natural units such as glaciers, plankton or dandelions adapt to and co-evolve with new conditions.

“Humans do not behave in this way; most resist change and stand in its way. By doing so, they create consequences for all species”, clarified MoMa curator Paula Antonelli in her contribution on YouTube. Oxman: “Nature does it best”. Why not copy as much as possible from it?

Read more

Read less

Interview

At HafenCity University Hamburg, Professor Antje Stokman combines architecture, ecology, technology and urban planning.

You are currently collaborating with 35 international cities and institutions on a five-year EU project with the name “CLEVER Cities”. What is it that makes a city and its buildings clever?Antje Stokman: In this case, it means utilizing the materials and mechanisms of nature and working with nature instead of against it with concrete and technology. Real estate and cities can be planned from the ground up in such a way that they will provide ecosystem-services; in other words, they will not only use their environment but that they will also be of service to it. A façade, for example, can be constructed so that plants will be able to contribute significantly to the shading and cooling of the building without consuming energy or warming ambient air, as is commonly the case with air conditioners.

How strongly is this approach taken into consideration?

Over the past few years, the topic has gathered momentum, impacting the classic professions. Truly sustainable building is an interdisciplinary endeavor of architects, construction engineers, materials scientists, technicians and urban planners. At the same time, more participation is essential. The top-down approach – something is planned from above without involving the local people, their ideas and their knowledge – will not lead to the best outcome.

It sounds as though sustainable building will definitely incur increased costs?

It depends on how you make up the balance. Initial investments may be higher. If, however, you consider the costs of the entire life cycle which, in the case of buildings, encompasses the long term, sustainable models are more cost-effective. Green roofs for example, which protect buildings and retain rainwater, recover their cost after approximately 20 to 40 years while generating additional value appreciation through their livable green environment.

Read more

Read less

Image source: Getty Images

Bacteria as concrete

A Dutch marine biologist invented a bio-concrete with self-healing properties. Bacteria that normally live in alkaline lakes can survive up to 200 years in concrete – without oxygen or nutrients. In case of damage and the resulting contact with water, the bacteria “awaken”, utilizing calcium lactate as a source of nutrition. The ensuing waste product, limestone, then seals the cracks.

Read more

Read less

Image source: alamy

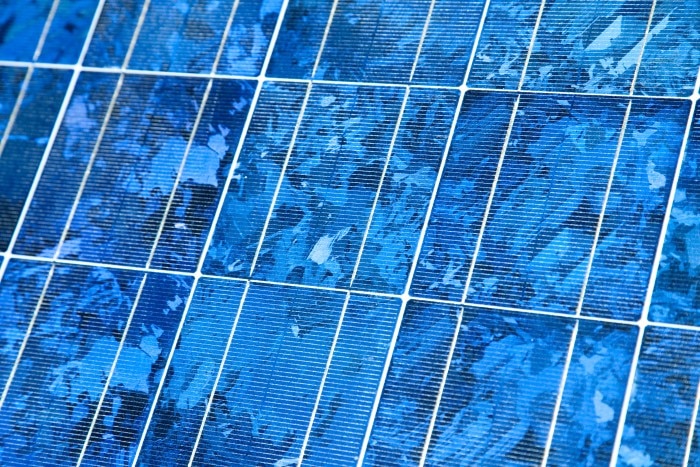

Windows as energy generators

Transparent solar cells have been a topic of conversation for a number of years. Until now, they had a color cast and were not particularly efficient when compared with traditional solar cells. South Korean researchers have now developed color-neutral, transparent solar cells made from silicon circuit boards which are also flexible. This opens up new possibilities for application – for example, as windows.

Read more

Read less

Image source: shutterstock

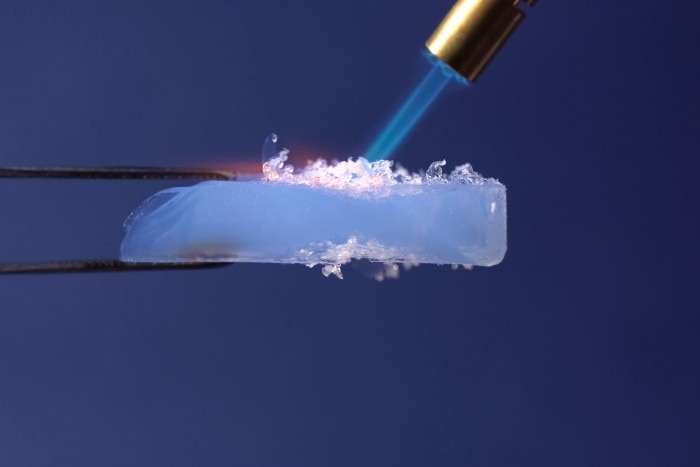

Astronomical insulation

Aerogels are highly porous solid bodies consisting of amorphous silicon dioxide. 90 percent of their volume is made up of tiny air-filled pores which ensure that energy-conductivity, which depends on the movements of air molecules, is extremely diminished – the perfect insulator. Originally

developed by the US Space Agency NASA for the Space Shuttle, they are now also used in the construction sector.

developed by the US Space Agency NASA for the Space Shuttle, they are now also used in the construction sector.

Read more

Read less