-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

The Carbon Footprint

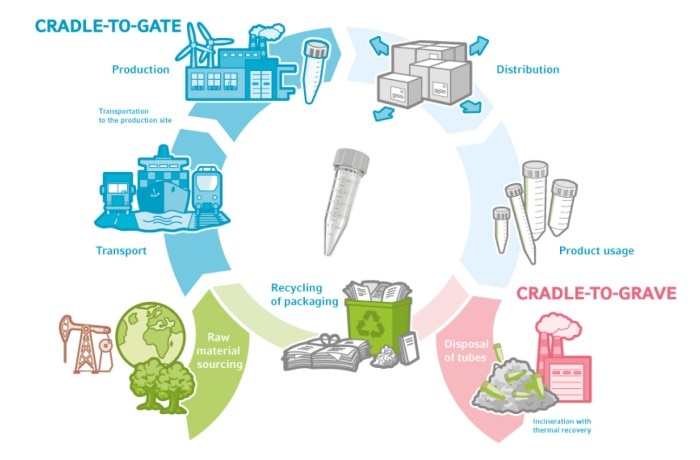

The carbon footprint of a product is more and more turned into the spotlight. A comprehensive view of the entire life cycle of a product is essential in order to understand and quantify environmental impacts. Such life cycle thinking is crucial both in designing new products and in sustainable improvement of existing ones. There are currently two ways to calculate the carbon footprint:

- The Life Cycle Analysis (LCA) is a method to assess the most important environmental impacts across the whole life cycle of a product. This also includes the major environmental impacts across the whole life cycle.

- The Product Carbon Footprint (PCF) focuses on the carbon footprint itself. (Also known as Product Carbon Analysis (PCA).

The Eppendorf biobased consumables have been developed under the assumption that biobased material of the 2nd generation can reduce the carbon footprint of these products. After establishing the production of biobased tubes, we decided to perform an externally developed and verified LCA for the 5 mL tube, comparing the fossil oil-sourced variant with the biobased variant.

Generation 1

1st generation bio-based plastic is crafted from agricultural sources such as sugar corn, sugar beet, potatoes, or corn. Most of today’s bio-based plastics come from these sources. They generally have a lower carbon footprint compared to fossil fuel-based plastics. However, there are also negative impacts, such as alterations in land use, the shift from natural landscapes like forests or meadows to farmland and the increased use of fertilizer and pesticides.

Generation 2

The 2nd generation bio-based plastic is crafted from waste streams, such as food waste, wheat straw from agricultural sources, or waste water streams. The adverse impacts associated with 1st generation materials are reduced

Generation 3

3rd generation bio-based plastic stems from seaweed and brown or red algae. These organisms produce polysaccharides which are the basis for various plastic materials.

Therefore, although the cradle-to-grave version uses more data and is more comprehensive, it is often also less accurate and based on extrapolations or estimations. The cradle-to-gate version is therefore in general more accurate in the data and has a higher information value.

Read more

Read less

Currently, at least 90% of the material of the biobased 5 mL tubes are crafted from biobased polypropylene (PP), sourced from waste streams within the food industry. At maximum 10% of the PP still relies on fossil resources. The lid in particular is still made from 100% fossil-sourced HDPE. The functional units were defined as follows:

- Bag with 200 x 5 mL sterile screw-cap tubes, bio-based, split into two bags (0030122321)

- Bag with 200 x 5 mL sterile screw-cap tubes, fossil-based, split into two bags (0030122518)

Different scenarios have been analyzed:

| Description | Case | Details: Usage of |

|---|---|---|

| Past / fossil reference | Fossil basis scenario (0-100) | Tube: 100% fossil-based PP Lid: 100% of fossil-sourced HDPE |

| Now | Biobased basis scenario (90-10) | Tube: 90% biobased + 10% fossil-sourced PP Lid: 100% of fossil-sourced HDPE |

| Future | Biobased (100-0) + (100) HDPE | Tube: 100% biobased + 0% fossil-sourced PP Lid: 100% of biobased HDPE |

Read more

Read less

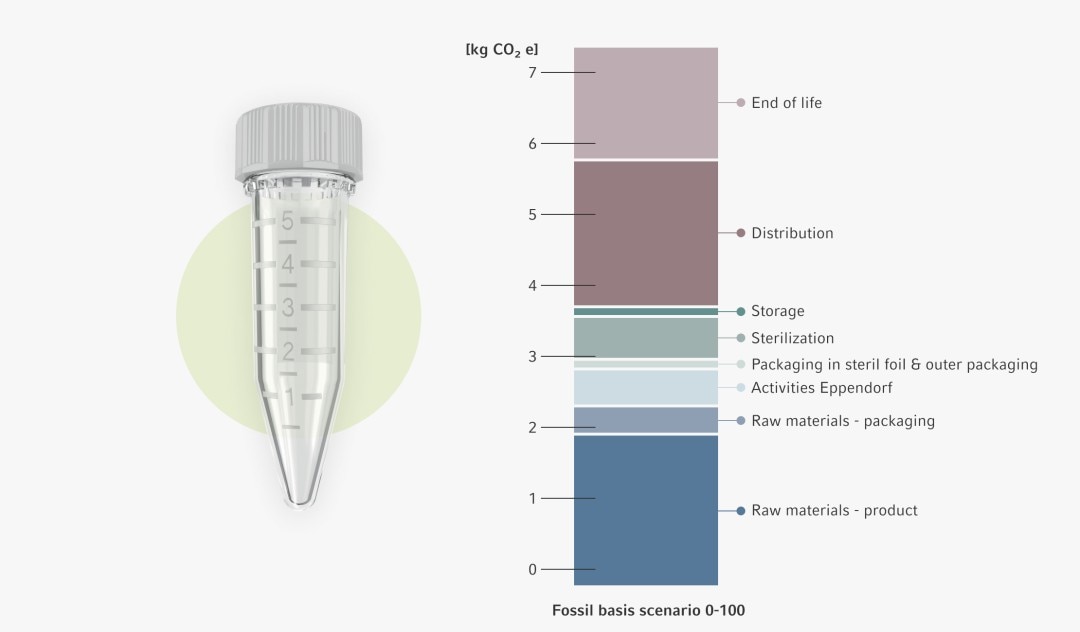

Carbon emissions during life cycle

Read more

Read less

With the complete dataset from the life cycle inventory, the impact assessment was conducted, revealing three key findings:

First finding: Raw materials of the product, distribution and end of life contribute the most to CO2eq. emissions. These are also the biggest levers for improvement.

Second finding: The goals of the study had to be slightly adapted - the decision was taken to focus only on greenhouse gas emissions and to skip other environmental impacts due to their inherent complexity and associated uncertainties. Moreover, CO2eq. emissions and their impact on global warming are widely acknowledged as the most important environmental impact. Secondly, a cradle-to-gate approach was analyzed in detail. Eppendorf has the biggest influence and potential for improvement in these first stages of the product life cycle. Furthermore, the data regarding end-of-life scenarios in different countries was incomplete and not comparable, as previously mentioned.

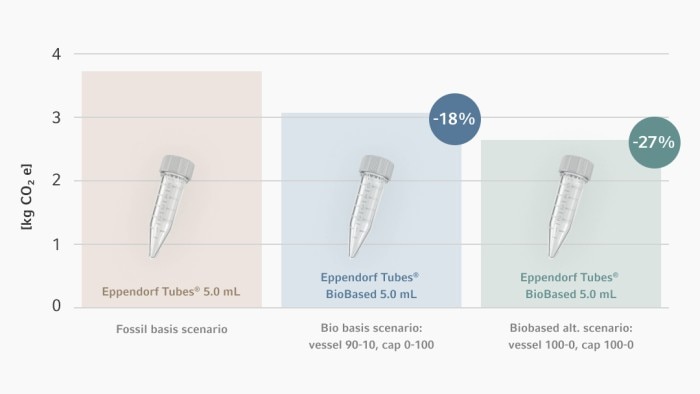

Third finding: Greenhouse gas emissions can be reduced by switching from fossil-sourced to biobased scenarios.

Global warming potential of selected scenarios from cradle-to-gate per unit (200x) for Eppendorf Tubes® 5.0mL

A detailed analysis of various cradle-to-gate scenarios demonstrated how much greenhouse gases are saved by using biobased material.

Today’s biobased 5 mL tubes already show a 17.8% decrease in greenhouse gas emissions compared to their fossil-sourced counterparts.

Based on the LCA of the 5 mL tubes, we calculated the CO2 savings for the other tube volumes regarding the biobased raw materials (cradle-to-gate).

| Tube | Carbon savings* ( raw material) cradle to gate per tube [CO2-eq.] |

|---|---|

| Eppendorf Tubes® Biobased 5.0 mL | 3.3 g |

| Eppendorf Tubes® Biobased 15 mL | 5.6 g |

| Eppendorf Tubes® Biobased 25 mL | 6.7 g |

| Eppendorf Tubes® Biobased 50 mL | 11.1 g |

Read more

Read less

Switching to 100% biobased 5 mL tubes manufactured from second-generation PP and 100% biobased HDPE can yield a 27% reduction in greenhouse gas emissions.

Learnings:

- Performing an LCA study is complex, even for seemingly “simple” products like tubes containing only two different materials (HDPE, PP). It will be even more complex for instruments which involve a lot more materials and extensive supply chains.

- Carrying out an LCA study is time-intensive due to the extensive data retrieval and the numerous review processes.

- LCA studies cannot be carried out for all products due to its complexity and time intensity. Instead, key products are primarily examined in order to draw general conclusions that apply to an entire product range.

Read more

Read less