MENU

CH | CHF

CH | CHF

No results found

Search Suggestions

Cell Culture Scale-Up Using Stirred-Tank Single-Use Bioreactors

Lab Academy

- Bioprocessing

- Bioprocess

- Cell Culture

- Scalability

- Essay

Read, how bioreactor characterization helped scaling-up a cell culture biprocess in single-use bioreactors.

An introduction to cell culture scale-up

In bioprocess development, the working volume in the R&D phase is typically small and increases as development progresses. During cell culture scale-up, process performance optimized at small scale needs to be reproduced at larger scale, ideally without much need for process optimization at large working volumes. In this article we discuss, how we characterized the BioBLU® c Single-Use Bioreactor portfolio to streamline cell culture scale-up and demonstrate, how we scaled-up the working volume of a cell culture process for mAB production from 3 L to 150 L, using single-use bioreactors at all stages.

Read more

Read less

Why is cell culture scale-up important?

Bioprocess development usually is carried out in systems with small working volumes. This helps save time and resources because, at small scale, several experiments can be conducted in parallel. Costs for media are kept low, and relatively little laboratory space is required to operate small-scale bioreactors. But over the course of development, biopharmaceutical companies need more material for characterization, trial runs, and finally for commercialization. They transition to bench scale and then up to pilot/production scale with the intent to maintain constant yield and constant product characteristics. This requires reproducing the cells’ growth environment across scales.

Read more

Read less

How to scale-up a cell culture bioprocess?

Reproducing the cells’ growth environment at different scales

Various parameters define the cells’ growth environment in a stirred-tank bioreactor such as the concentration and distribution of nutrients, the concentrations of dissolved oxygen and CO2, and mechanical stress. These parameters are influenced by the bioreactor’s capabilities and equipment, like the volumetric mass transfer coefficient (kLa), impeller type, and gassing devices, as well as by process parameters, like the agitation speed and gas flow rate.

Developing a scale-up strategy

Keeping one process parameter constant will change others. Therefore, we can only partially reproduce the cells’ growth environment at different scales. The bioengineer must identify the parameters which influence cell growth and productivity most, to decide, which scale-up strategy is the most suitable. Often scientists decide to keep at least one parameter constant across scales, such as

For more detailed information on these parameters, the different scale-up strategies and their pro’s and con’s please visit our bioprocessing scale-up page.

Various parameters define the cells’ growth environment in a stirred-tank bioreactor such as the concentration and distribution of nutrients, the concentrations of dissolved oxygen and CO2, and mechanical stress. These parameters are influenced by the bioreactor’s capabilities and equipment, like the volumetric mass transfer coefficient (kLa), impeller type, and gassing devices, as well as by process parameters, like the agitation speed and gas flow rate.

Developing a scale-up strategy

Keeping one process parameter constant will change others. Therefore, we can only partially reproduce the cells’ growth environment at different scales. The bioengineer must identify the parameters which influence cell growth and productivity most, to decide, which scale-up strategy is the most suitable. Often scientists decide to keep at least one parameter constant across scales, such as

- Impeller tip speed: It influences culture mixing and therefore the distribution of nutrients and oxygen transfer but also shear forces that act on the cells.

- Power input/volume ratio (P/V): It influences oxygen transfer and culture mixing, as well.

- Volumetric mass transfer coefficient (kLa): Describes the efficiency with which oxygen can be delivered to a bioreactor culture. It depends on parameters like agitation speed, impeller type, gas flow rate, and others.

For more detailed information on these parameters, the different scale-up strategies and their pro’s and con’s please visit our bioprocessing scale-up page.

Read more

Read less

What are the advantages of stirred-tank single-use bioreactors?

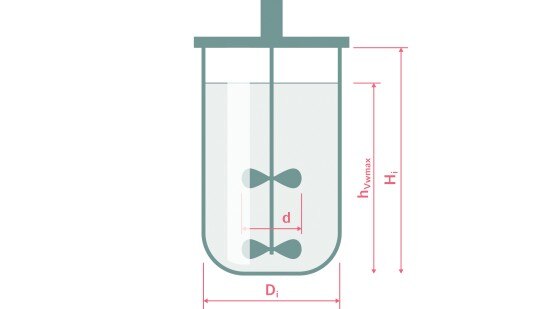

Today, stirred-tank bioreactors are the most widely used bioreactor type in the biotech and pharma industry. Process scale-up is comparably easy, because the stirred-tank bioreactor design is relatively easy to describe with classical engineering approaches (Figure 1) and because it is the bioreactor design for which most research on scale-up phenomena has been conducted. This knowledge has been transferred into single-use technology, as well.

Read more

Read less

Figure 1: Parameters to describe the geometry of a stirred-tank bioreactor include impeller diameter (d), bioreactor inner diameter (Di), liquid height at maximum working volume (hVwmax), bioreactor inner height (Hi), and ratios thereof.

In the development and manufacturing of biologics today, single-use bioreactors are often favored over glass and stainless-steel vessels, because their use saves time and mitigates risks: The omission of laborious cleaning procedures saves time, increases turn-around time, and lowers the risk of cross-contamination.

BioBLU® c Single-Use Bioreactors

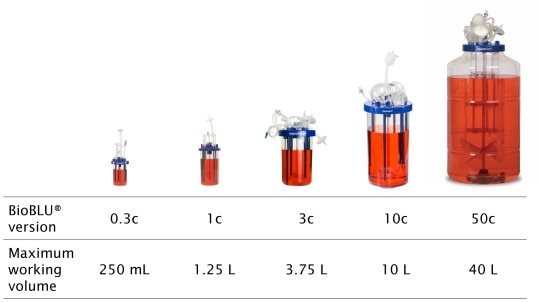

The BioBLU® c Single-Use Bioreactor portfolio from Eppendorf combines the benefits of single-use bioreactor technology with the reliable performance and scalability of conventional glass or stainless-steel bioreactors. With industry standard dimensions the BioBLU® family supports effective mixing and mass transfer as well as reproducible cultivation conditions across scales.

BioBLU® c Single-Use Bioreactors

The BioBLU® c Single-Use Bioreactor portfolio from Eppendorf combines the benefits of single-use bioreactor technology with the reliable performance and scalability of conventional glass or stainless-steel bioreactors. With industry standard dimensions the BioBLU® family supports effective mixing and mass transfer as well as reproducible cultivation conditions across scales.

Read more

Read less

- Scalable design from 100 mL to 40 L

- The rigid wall stirred–tank design mimics traditional bioreactors

- Bioreactor body and head plate comprised of single layer injection molded plastic. Virgin raw materials: no risk from use of recycled materials

Read more

Read less

Eppendorf single-use bioreactor portfolio

Eppendorf offers comprehensive single-use solutions for cell culture scale-up from 100 mL up to 2000 L.

Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

- BioBLU® c Single-Use Bioreactors cover working volumes of 100 mL to 40 L and are compatible with Eppendorf bioreactor control stations at small and bench scale.

- BioFlo® 720 bioreactor control station, compatible with Thermo Scientific® HyPerforma® single-use bioreactors as well as the BioBLU® 50c Single-Use Bioreactor

Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

Read more

Read less

BioBLU® c Single-Use Bioreactor characterization for simplified cell culture scale-up

When thinking about how to scale-up a cell culture bioprocess , scientists often decide to keep one parameter constant across scales, like the tip speed, kLa, or power input per volume.

Whichever scale-up strategy the investigator chooses, two important considerations need to be taken into account. First, the tip speed range, kLa range, and the P/V range, respectively, of the differently sized bioreactors need to overlap to some extent to be kept constant across scales. Second, information on certain bioreactor engineering parameters is required to define this overlap. This is why we have investigated the scale-up capabilities of Eppendorf BioBLU® Single-Use Bioreactors for cell culture applications for culture scale-up from small to pilot scale.

Whichever scale-up strategy the investigator chooses, two important considerations need to be taken into account. First, the tip speed range, kLa range, and the P/V range, respectively, of the differently sized bioreactors need to overlap to some extent to be kept constant across scales. Second, information on certain bioreactor engineering parameters is required to define this overlap. This is why we have investigated the scale-up capabilities of Eppendorf BioBLU® Single-Use Bioreactors for cell culture applications for culture scale-up from small to pilot scale.

Read more

Read less

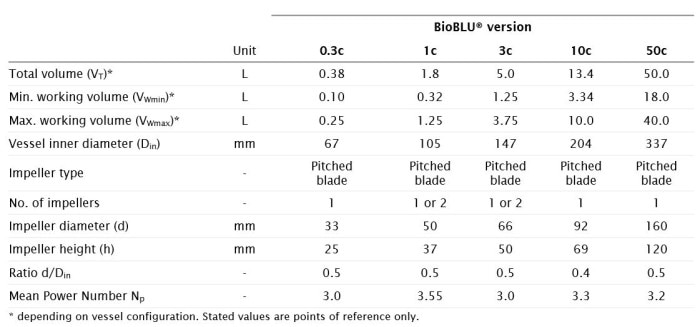

Bioreactor geometries

BioBLU® Single-Use Bioreactors from small scale to pilot scale are of geometrically and proportionally similar stirred-tank designs (Table 1). Read more

Read less

Table 1: BioBLU® Single-Use Bioreactor vessel geometries. Displays scale-up relevant geometrical parameters of the BioBLU® Single-Use Bioreactors and impellers. It demonstrates that the BioBLU® Single-Use Bioreactors from small scale to pilot scale are of geometrically and proportionally similar stirred-tank designs.

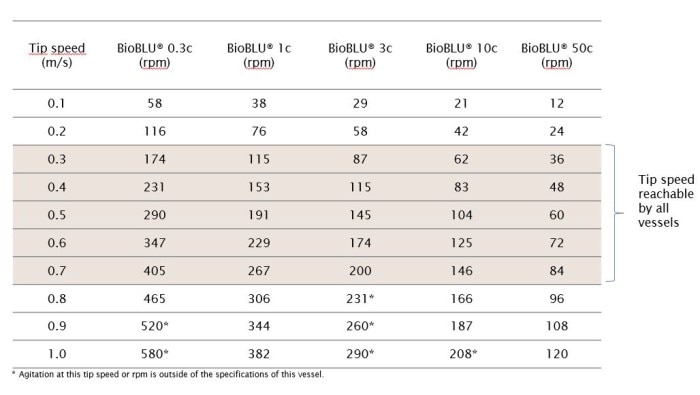

Identifying a scalable tip speed zone

Tip speed is an important parameter for cell culture scale-up. Scale-up based on maintaining constant tip speed is one of the common strategies, especially for cultures sensitive to shear force damage. We identified 0.3 to 0.7 m/s as the tip speed scalable zone of the BioBLU c Single-Use Bioreactors, i.e. the tip speed range that all BioBLU® c Single-Use Bioreactors can reach (Table 2). Read more

Read less

Table 2: The correlation of impeller tip and agitation speed was calculated for different BioBLU® c Single-Use Bioreactors using the following equation: Tip speed (m/s) = π x impeller outer diameter (m) x agitation speed (rps)

Identifying a kLa-based scalable zone

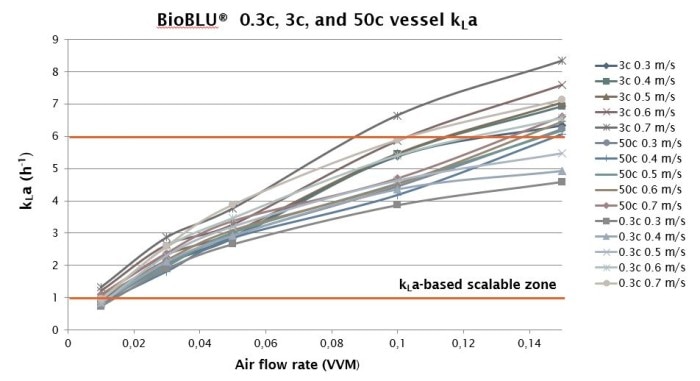

Oxygen transfer is one of the most critical scale-up parameters for bioreactors, and it can be represented in the form of the volumetric mass transfer coefficient, kLa. When oxygen transfer is the rate limiting factor for a cell culture process, maintaining constant kLa can achieve scalable yield from small to large scale. For proper cell culture scale-up, it is important to select equipment of different sizes with similar kLa capabilities that offer sufficient overlapping so that the small scale success can be replicated in large scale. As an example, we determined the kLa of differently-sized BioBLU® c Single-Use Bioreactors (BioBLU 0.3c, 3c, and 50c) using the static gassing-out method [1] and identified a kLa-based scalable zone between a kLa of 1 and 6 h-1 (Figure 2). kLa values in this range can be reached by all BioBLU® c Single-Use Bioreactors tested and therefore replicated across scales.

Find more information on dissolved oxygen (DO) control in bioreactors .

Read more

Read less

Figure 2: kLa values of BioBLU® 0.3c Single-Use Bioreactors with open pipe sparger, BioBLU® 3c Single-Use Bioreactors with macrosparger, and BioBLU® 50c Single-Use Bioreactor with macrosparger were determined at different tip speeds and air flow rates (vessel volume per minute, VVM) using the static gassing out method [1]. We identified a kLa-based scalable zone between a kLa of 1 and 6 h-1. kLa values in this range can be reached by all BioBLU® c Single-Use Bioreactors tested.

Identifying a P/V-based scalable zone

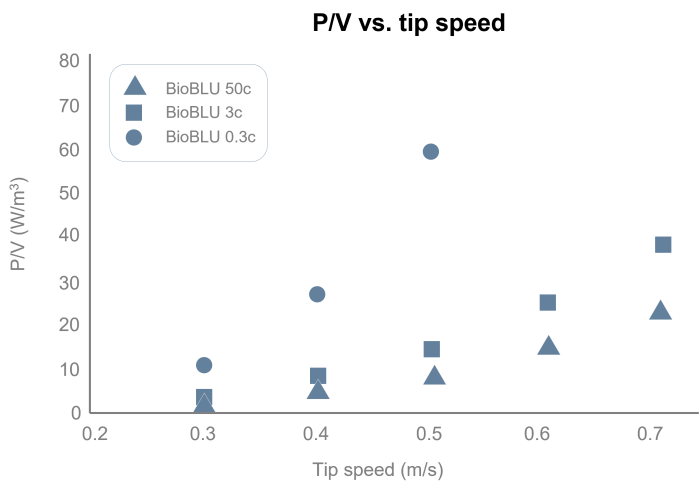

Maintaining a constant impeller power consumption per liquid volume (P/V) between bioreactors is one of the most prevalent strategies for scale-up. To calculate it, the impeller power number Np (also known as Newton number, Ne) is needed. Np is a dimensionless number associated with each type of impeller. However, the measurable power numbers vary depending on various factors of the bioreactor set-up. The industry standard method to determining Np is to measure the impeller torque by using a rotational torque sensor. We have determined the power number for the differently sized BioBLU® Single-Use Bioreactors according to a protocol recommended by the DECHEMA® [1] (Table 1). Using the Np values, it is possible to identify a scale-up zone, within which P/V values can be achieved by the bioreactor types of interest by applying a tip speed which is within the technical specification of the bioreactors. Figure 3 shows exemplarily the correlation of P/V and tip speed for the BioBLU® 0.3 c, 3c, and 50 c Single-Use Bioreactors, respectively.

Read more

Read less

Figure 3: Bioreactor power numbers were measured according to DECHEMA recommendations [1] and as summarized below. P/V was calculated as P/V [W/m3[ = (impeller power number x DI water density [kg/m3] x agitation speed [rps]3 x impeller outer diameter [m]5 )/ full working volume [m3] To measure power numbers, the bioreactors were modified to remove the magnet from the magnetic drive coupling and the torque sensor was connected in between the motor and impeller shaft using custom adaptors through a modified head plate. All data were collected on standard bioreactors with one impeller with clockwise agitation/up flow; The vessels were filled with deionized water to maximum working volume. All data, including dead weight torque, were collected as an average of 300 readings per measurement. Impeller torque measurements were repeated 5 times at each tip speed with no aeration. Data collection were done at ambient temperature of 24.5°C. The power numbers are an average of two BioBLU® Single-Use Bioreactors for each size.

Case study: Cell culture scale-up using single-use bioreactors

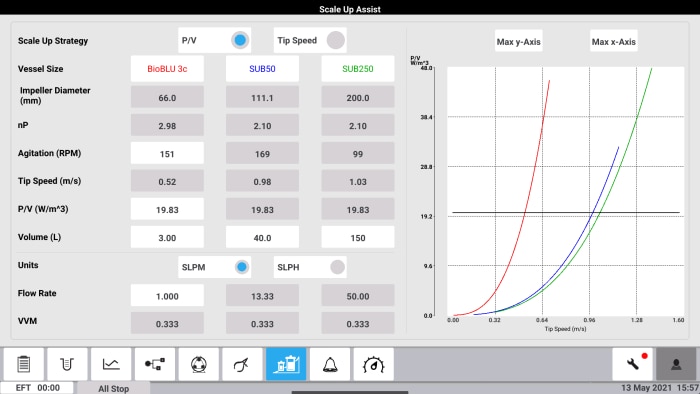

In a proof of concept study we developed a CHO cell culture scale-up workflow, which uses single-use bioreactors at all stages from bench to pilot production scale. For the scale-up strategy we selected the option of maintaining a constant P/V. To simplify cell culture scale up we used the Scale Up Assist software feature of the BioFlo® 320 and BioFlo® 720 bioreactor control stations from Eppendorf.

Scale Up Assist software feature for simplified cell culture scale-up

Both P/V and the impeller tip speed depend on the agitation speed. To keep P/V or tip speed constant when transferring the bioprocess to a differently-sized bioreactor, the agitation speed needs to be adapted accordingly. The Scale Up Assist software (Figure 4) feature from Eppendorf simplifies this process. The software is auto-populated with the power numbers and impeller diameters of various bioreactor types. The scientists only need to select the desired bioreactor types from a list and to enter the working volumes. The software then calculates the agitation speed which results in a defined P/V value or tip speed at the selected working volume. The Scale Up Assist is a software feature of the BioFlo® 320 and BioFlo® 720 bioreactor control stations from Eppendorf.

Scale Up Assist software feature for simplified cell culture scale-up

Both P/V and the impeller tip speed depend on the agitation speed. To keep P/V or tip speed constant when transferring the bioprocess to a differently-sized bioreactor, the agitation speed needs to be adapted accordingly. The Scale Up Assist software (Figure 4) feature from Eppendorf simplifies this process. The software is auto-populated with the power numbers and impeller diameters of various bioreactor types. The scientists only need to select the desired bioreactor types from a list and to enter the working volumes. The software then calculates the agitation speed which results in a defined P/V value or tip speed at the selected working volume. The Scale Up Assist is a software feature of the BioFlo® 320 and BioFlo® 720 bioreactor control stations from Eppendorf.

Read more

Read less

Figure 4: Scale Up Assist Screen

Comparable cell growth and antibody production from 3 L and 150 L

We scaled-up a CHO cell culture bioprocess for mAB production from 3 L to 10 L in BioBLU® Single-Use Bioreactors and further up to 40 L and 150 L in Thermo Scientific HyPerforma SUBs, controlled by a BioFlo® 320 and BioFlo® 720 controller, respectively. By using the parameters calculated by Scale Up Assist feature and described in detail in our application note, we could match the growth profiles across all platforms in multiple batch runs with working volumes between 3 L and 150 L. All runs yielded similar IgG production values when they reached completion.

We scaled-up a CHO cell culture bioprocess for mAB production from 3 L to 10 L in BioBLU® Single-Use Bioreactors and further up to 40 L and 150 L in Thermo Scientific HyPerforma SUBs, controlled by a BioFlo® 320 and BioFlo® 720 controller, respectively. By using the parameters calculated by Scale Up Assist feature and described in detail in our application note, we could match the growth profiles across all platforms in multiple batch runs with working volumes between 3 L and 150 L. All runs yielded similar IgG production values when they reached completion.

Read more

Read less

Interested in all the details of the case study? Check out our Application Note

Read more

Read less

References:

[1] DECHEMA Expert Group Single-Use Technology; Recommendations for process engineering characterization of single-use bioreactors and mixing systems by using experimental methods (2nd edition); 2020 https://dechema.de/en/Single_Use_PE_Characterization-path-123211,124930.html Read more

Read less

Related Webinar:

Read more

Read less