-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

- LabDays 2025

- ILMAC 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

- LabDays 2025

- ILMAC 2025

- ASIA LABEX: The Lab Show 2025

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

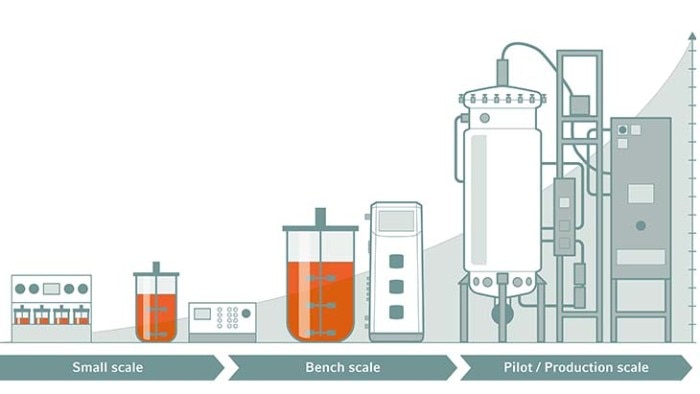

Bioprocessing Scale Up

Read more

Read less

Moving to a bioreactor

Read more

Read less

Bioprocess scale up strategies

An established strategy when transitioning to larger working volumes is to monitor and control a single parameter. However, keeping one process parameter constant will change others; therefore, the cells’ growth environment can only be partly reproduced at different scales. Bioengineers must identify the parameters which influence cell growth and productivity most, to decide, which scale up strategy is the most suitable. Although bioprocessing scale up strategies that control several criteria are the most powerful, those that control singular parameters can still be effective, and are historically the most widely used due to their simplicity. Common singular parameters to control include:

Constant power input per liquid volume

- Np: the impeller power number (also known as Newton number),

- ρ: DI water density (kg/m3 ),

- N: agitation speed (rps),

- D: impeller outer diameter (m)

- V: full working volume (m3 ).

Read more

Read less

Read more

Read less

Read more

Read less

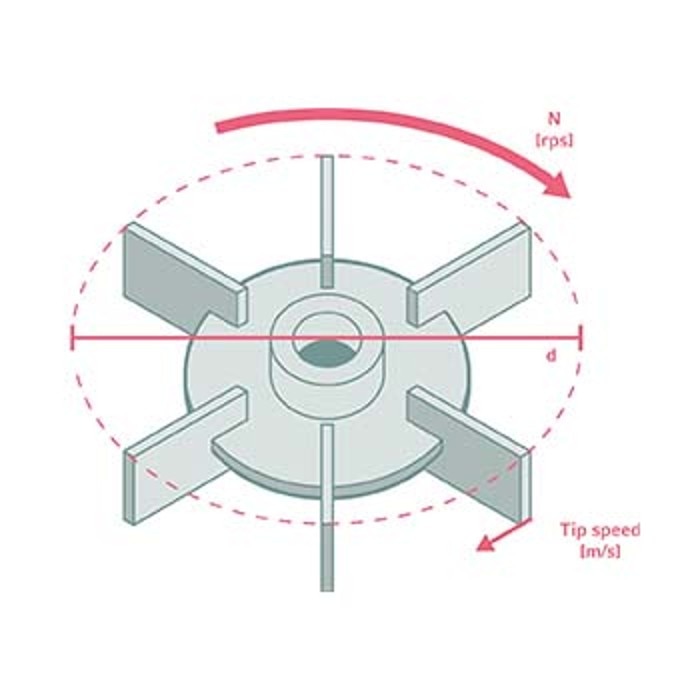

Constant tip speed

Definition: The impeller tip speed equals π x d x N, with

- D: impeller outer diameter (m)

- N: agitation speed (rps)

Read more

Read less

Read more

Read less

Constant kLa

Read more

Read less

Read more

Read less

Read more

Read less

Constant mixing time

Read more

Read less

Read more

Read less

Read more

Read less

Scale-up strategies: recommended resources

- Watch our webinar to find out more about bioprocess scale up strategies and how we scaled-up a cell culture bioprocess from 3 L to 40 L.

- Read in our application note , how we investigated scale up-relevant engineering parameters for differently sized fermentors, including power numbers, tip speed range, and oxygen transfer capabilities.

Read more

Read less

Which factors are relevant during bioprocessing scale up?

As depicted above, a tailored scale up strategy is needed to reproduce product yield and quality in an upstream bioprocess across scales. Various other factors need to be considered as well while scaling-up, including space requirements in the lab, staff training, equipment choice, and scaling-up the downstream process. In this panel discussion, industry experts from Eppendorf and other companies share their thoughts on scale up challenges from an economical, operational, and application-related point of view.

Eppendorf products for powerful bioprocessing scale up

- Small-scale: DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems

- Bench-scale: SciVario® twin , BioFlo® 120 , BioFlo® 320

- Pilot/production-scale: BioFlo® 510 , CelliGen 510 , BioFlo® 610 , BioFlo® Pro , BioFlo® 720

Read more

Read less

Cell culture scale up

- Single-use bioreactors: The BioBLU® c Single-Use Bioreactor portfolio covers working volumes from 100 mL to 40 L. To make the progression from bench-scale to production-scale, the BioFlo® 720 is a bioreactor control system which is compatible with Thermo Scientific™ HyPerforma™ 5:1 Single-Use Bioreactors with working volumes up to 2000 L.

- Glass bioreactors: Eppendorf glass bioreactors for cell culture applications cover working volumes from 60 mL to 10.5 L and are compatible with the small and bench scale Eppendorf bioprocess systems .

- Sterilize in place systems: The CelliGen 510 bioreactor control system covers working volumes from 10.5 L to 32 L.

Read more

Read less

Fermentation scale up

- Glass bioreactors: Eppendorf glass bioreactors for microbial applications cover working volumes from 60 mL to 10.5 L and are compatible with the small and bench-scale Eppendorf bioprocess systems .

- Sterilize in place systems: The BioFlo® 510 , BioFlo® 610 and BioFlo® Pro cover working volumes from 16 L to 2400 L.

- Single-use bioreactors: The BioBLU® f Single-Use Bioreactor portfolio covers working volumes from 65 mL to 3.75 L. These stirred-tank bioreactors fully address the specific needs of fermentation. Read more about the scalability of E. coli fermentation in BioBLU® f Single-Use Bioreactors.

Read more

Read less

Scalable portfolio

Read more

Read less

How our customers use our products

Read more

Read less