ISO 23783: The Premium Calibration Retreat for Automated Liquid Handler

Dr. Stefanie Rösel Lab Academy

- Pharma

- Molecular Biology

- Biotechnology

- Forensic

- Microbiology

- Services

- Liquid Handling Workstations

- Pipetting & Dispensing

- Pipetting Ergonomics

- Pipetting Techniques

- Accuracy

- Pipette Maintenance

- Automation

The new ISO 23783 is coming. Find out what is behind it and discover the benefits of calibrating your automated liquid handling system in an ISO 23783 and ISO 17025-compliant facility. Learn how to enjoy greater peace of mind about the quality of your results, boost lab productivity, and how to easily meet regulatory requirements!

Greater peace of mind about the quality of your results while ensuring compliance with regulatory requirements.

Is your lab required to adhere to specific regulations, or are you aiming to align your processes with universally recognized standards? If so, consider sending your pipetting robot to a true premium calibration retreat encompassing ISO 23783 services in an ISO 17025-certified facility.

You can enjoy serious benefits, so it is definitely worth it:

- Enhance your lab's productivity

- Guarantee the quality and safety of results

- Ensure compliance with regulatory requirements

- Spend less time on audit preparations

Read more

Read less

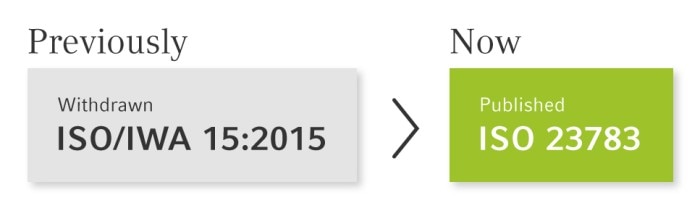

ISO 23783: A New Standard for Automated Liquid Handling System Calibration

Read more

Read less

What is the ISO 23783 standard about?

The ISO 23783 defines procedures and data for factory/calibration labs (Factory Acceptance Test - FAT) and on-site/customer labs (Sight Acceptance Test - SAT). The procedures include the estimation of measurement uncertainties and established traceability to reference standards.

Read more

Read less

The ISO 23783 consists of three parts:

Types of automated liquid handling systems (ALHS) are described, as well as specific use requirements, settings, and adjustments for each ALHS type. Also, environmental requirements are described for the use of ALHS, e.g.:

- Factory acceptance testing

This should be performed in a location where at least the temperature and relative humidity can be controlled. - Site acceptance testing

ALHS could be installed and used in locations where environmental conditions differ from factory testing conditions. Site acceptance testing should be performed at prevailing local conditions, which should be stable within the requirements of the test method and the ALHS manufacturer’s specifications.

This part specifies procedures for the determination of volumetric performance of ALHS, including traceability and estimations of measurement uncertainty of measurement results.

The method and its suitability for the specific test situation shall be evaluated. The suitability of a method for a given test situation may also be determined by the required equipment or environmental conditions under which it needs to be carried out:

- Photometric method suitable for up to 384 channels

- Fluorescence method suitable for volumes smaller than 15 nl

- Gravimetric for non-contact liquid delivery devices

- Hybrid gravimetric/photometric hybrid method suitable for the determination of the systematic and random error of 96 or 384 devices

For all methods and procedures mentioned above a detailed operation description is given in the ISO 23783 standard.

Part 3: Determination, specification and reporting of volumetric performance3

The third part provides guidance and establishes requirements for collecting and examining volumetric performance data of ALHS. It specifies how to index and track volumetric performance data and provides descriptive statistics for the evaluation of these data. This part also specifies reporting requirements of ALHS volumetric performance, e.g.:

- Results shall be reported, usually in a test report or a calibration certificate, and shall include all of the information requested, necessary for the interpretation of the test or calibration results, and all information required by the specific test method used.

- The naming convention of reports and certificates is dependent on regional, national, or local guidelines and the following information should always be included in the document at a minimum:

- Name and address of testing

- Dates of calibration

- Name(s) of the person(s) performing the test

- Unique and clear identification on each page

- Description, and unambiguous identification, of the ALHS tested

- List, and identification, of all automatically, manually and other exchangeable components used during the test, and how many automatic and manual exchanges were performed for each of these components during the test.

- Calibration certificates shall include the following, unless there are valid reasons for not doing so:

- Measurement uncertainty of the calibration

- Measurement results are traceable to the SI unit of volume

- Calibration status of the measuring instruments used in the testing process

Read more

Read less

Who should do the calibration according to ISO 23783 for dispensing tools of automated liquid handling systems?

- Users of ALHS, as a basis for calibration, verification, validation, optimization, and routine testing of trueness and precision

- Manufacturers of ALHS, as a basis for quality control, communication of acceptance test specifications and conditions, and issuance of manufacturer’s declarations (where appropriate)

- Test houses and other bodies, as a basis for independent certification, calibration, and testing

Read more

Read less

Premium retreat: Make it happen with ISO 23783 & ISO 17025

Take advantage of interlaboratory comparisons, by employing ISO 23783 calibrations within an ISO 17025 calibration facility that utilizes standardized test protocols and conducts statistical validations outlined in ISO 23783. This establishes the prerequisite for comparing your results with those of other laboratories, ensuring you compare apples to apples and not apples to oranges.

Read more

Read less

This combination will not only accelerate your research but also help you avoid measurement uncertainty, maximizing data integrity while ensuring compliance with quality and regulatory requirements.

Regulated labs and those following best practices guidelines should consider calibrations and routine tests in ISO 17025-accredited facilities.

We recommend calibrating at least annually to maintain the precision of your ALHS!

New! Eppendorf ISO 23783 calibration available in selected markets

- Volumetric performance – featuring metrological traceability and estimations of measurement uncertainty of measurement results

- Compliance with quality and regulatory requirements (such as ISO 17025 and ISO 23783)

- Certificates featuring traceability and estimations of measurement uncertainty

- Inhouse calibration results documented as factory data (FAT = Factory Acceptance Test)

Read more

Read less

Peace of mind with carefully designed ISO 17025 service solutions

Explore our professional package, encompassing:

- 3x10 as-found calibration

- Comprehensive preventive maintenance, including the exchange of O-rings and worn-out parts, if required, and external and internal cleaning of the tool

- 3x10 as-left calibration

- Calibration certificate inclusive of measurement uncertainty, as-found and as-left reporting, and recommended calibration intervals if requested

In addition to our tool calibration service, our dedicated Application and Technical Service teams worldwide offer support for the entire range of epMotion devices:

- Qualification service to prepare for audits

- Preventative maintenance services to avoid unexpected downtime

- Assistance in implementing or optimizing your epMotion protocol

Read more

Read less

References:

2 Chapter to Part 2 in “23783-2 ISO Automated liquid handling systems – Measurement procedures for the determination of volumetric performance 2022-08.pdf”, https://www.iso.org/standard/76958.html

3 Chapter to Part 3 in “23783-3 ISO Automated liquid handling systems – Determination, specification and reporting of volumetric performance 2022-08.pdf, https://www.iso.org/standard/76959.html

4 The relevant accreditation body in this area is: INAB ( https://www.inab.ie/ )

Read more

Read less