MENU

US | USD

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

US | USD

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

No results found

Search Suggestions

GMP info

To get support with selecting the most suitable Eppendorf Bioprocess equipment for

your specific application, please reach out to your Eppendorf sales representative.

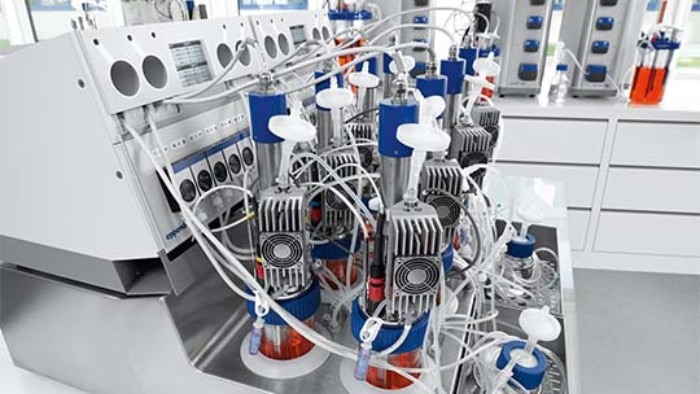

Bioprocessing in Vaccine Development

At Eppendorf, our aim is to empower your upstream bioprocessing in vaccine development. We provide tools that help you accelerate process development by parallel bioprocessing, increasing turn-around, and leveraging the full potential of bioprocess data. We support you in increasing cost-efficiency by intensifying bioprocesses and streamlining scale-up. You discover new ways for vaccine production. We deliver solutions to help bringing your bioprocess to the next level. So come and talk to us, we’re all ears.

Read more

Read less

Supporting you in your pursuit of efficiency

Speed up bioprocess development

We offer orchestrated bioreactor, software, and service solutions that let you combine experimental efficiency with smart use of data. Discover our bioprocess solutions that support you to increase speed through parallel processing, automation, and efficient data analysis. Find out how our software ecosystem can leverage the power of artificial intelligence to reduce the experimental workload in process development.

Read more

Read less

Scale-up to clinical and commercial manufacturing

Bioprocess insight gained at small-scale can help to ensure a high level of success in your large-scale processes. Our scalable bioprocess solutions help you seamlessly translate your R&D successes into manufacturing. Our solution package of bioprocess controllers, bioreactors, bioprocess SCADA software, and services support the compliance of your bioprocesses with GMP requirements in clinical and commercial manufacturing.

Read more

Read less

Intensify your bioprocess

We support you in increasing process productivity and lowering production costs. Our bioprocess controllers and software support the use of Process Analytic Technology (PAT) to fine-tune process control for improved reproducibility and quality. Our bioreactor systems let you choose between batch, fed-batch, and perfusion cultures to help optimize yield and productivity.

Read more

Read less

Reduce risks and save time with single-use technology

Our single-use technology helps you increase throughput, flexibility, and safety in bioprocessing. BioBLU® Single-Use Bioreactors eliminate the need for labor-intensive cleaning procedures, cleaning validation, and hold time validation. With built-in measures to minimize the risk of contamination, they enable you to act quickly while significantly reducing the risk of costly and time-consuming batch failures in both research and manufacturing environments.

Read more

Read less

Get to know the Eppendorf bioprocess products

The Eppendorf bioprocess portfolio offers scalable bioprocess systems, single-use bioreactors, software solutions, and services to efficiently develop processes and move them from R&D to manufacturing.

Read more

Read less