Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

What is a Bioreactor?

What is a bioreactor?

Bioreactors are useful for a wide range of applications at various scales of production. Continue reading to find out how the use of bioreactors can optimize your cell or microbial culture. Learn about the different components, cell types and applications suitable for bioreactor systems and receive expert advice on how to get started.

Read more

Read less

Why should you consider using a bioreactor?

Read more

Read less

Produce large quantities of cells

Read more

Read less

Decrease batch-to-batch variability

Read more

Read less

Find the best culture conditions

Read more

Read less

Shakers/incubators and bioreactors

If you are using bioreactors, you will probably use a shaker or incubator as well for early research and process development and inoculum preparation. This means, it depends on the application and the workflow stage, which cultivation system is the better choice.

- Get an overview on the strengths and weaknesses of shakers/incubators and bioreactors and at which workflow step the one or the other is particularly useful. Read more!

- Interested in an example? Read, how one of our customers optimized protein production in E. coli. Shake flasks were used at the beginning to optimize a range of process parameters. Subsequently, bioreactors have enabled a significant increase in productivity. Download case study!

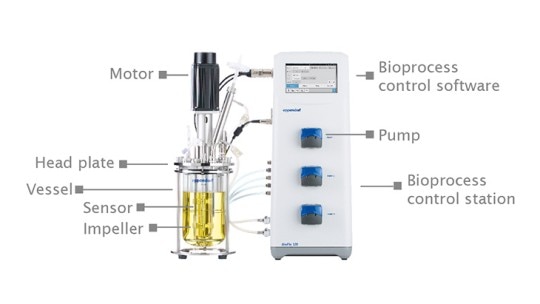

What are the main components of a bioreactor?

Read more

Read less

- Sensors: These monitor key process parameters, including pH, dissolved oxygen and temperature continuously in real-time. Various types of sensors can be integrated into bioreactors.

- Control software: Based on sensor readings, the software calculates the adjustments to the system that are required to maintain parameter levels within their specified setpoint.

- Actuators: Regulated by the control software, actuators can be pumps, valves, or motors, that adjust the parameter back to its specified setpoint.

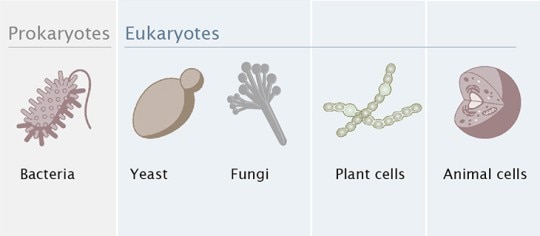

Which cell types can be cultured in bioreactors?

A broad range of cell types can be cultured in bioreactors, including:

- Mammalian cells , including stem cells

- Insect cells

- Bacteria

- Yeast and filamentous fungi

- Plant cells

What are typical application areas for bioreactors?

Read more

Read less

Life science and pharma

- Cells for cell therapy and drug discovery applications

- Viral vectors

- Monoclonal antibodies and other therapeutic proteins, peptides, hormones and enzymes

- Exosomes

- Vaccines

Read more

Read less

Food and feed

- Beer, wine

- Dairy products

- Amino acids, vitamins, and flavors

The production of cultured n meat is an up-and-coming use of stem cell cultures in bioreactors.

Read more

Read less

Chemicals

- Biofuels

- Platform chemicals

- Biopolymers

Read more

Read less

Which scales of production can bioreactors be used for?

- 100 mL range - small scale: Working volumes around 100 mL are typically used in R&D.

- Liter range - bench-scale: Working volumes of several liters are typically used for process development, during scale-up, and also for production processes.

- Hundreds of liters range - production-scale: Large-scale, commercial production often takes place in working volumes of hundreds or thousands of liters.

Read more

Read less

Considering using bioreactor systems for your bioprocess?

Read more

Read less

What you need to know before investing in a bioprocessing space in your lab:

There are important considerations to make when purchasing your first bioreactor. Get to know about the necessary lab infrastructure and about useful additional equipment like incubators and analyzers.

Contact us to select the right equipment

Read more

Read less