MENU

US | USD

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

US | USD

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

Sorry, we couldn't find anything on our website containing your search term.

Do You Worry About Your Samples?

Beyond Science

- Lab Life

- Essay

- Lab Life

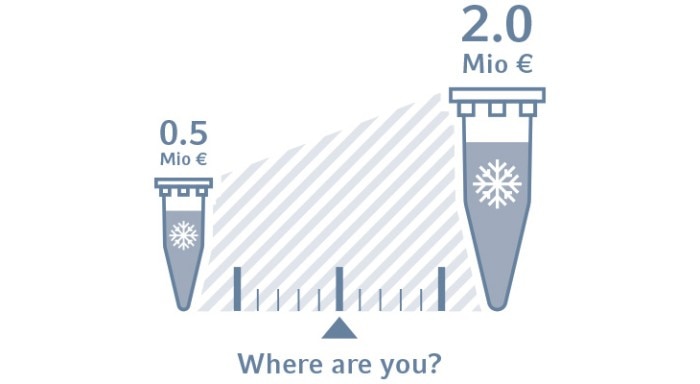

Despite all trends for energy saving, the goal of an ULT freezer should always be providing you a safe storage for your high-value samples. Did you ever calculate the value within your freezer? All the countless hours, days, weeks, months, and even years of work spent on your samples? More than 50,000 samples fit into the big standard ULTs. The value of every single sample differs, from simple buffers to high-value cell extracts or expensive enzymes. When assuming an average (low) value of 10 €/ vial, the inventory is already summing up to 500,000 € - or half a Million €.

When using mainly samples of high value and those which are a result of years of workload – you easily reach a value far beyond that half one Million € in your freezer. Your ULT freezer is not limited to be your storage room for vials. This instrument is your assurance for long-term scientific success, it guards the results of your work. Besides the insulation and the cooling technology, there are several control or backup aspects which needs to be evaluated.

Read more

Read less

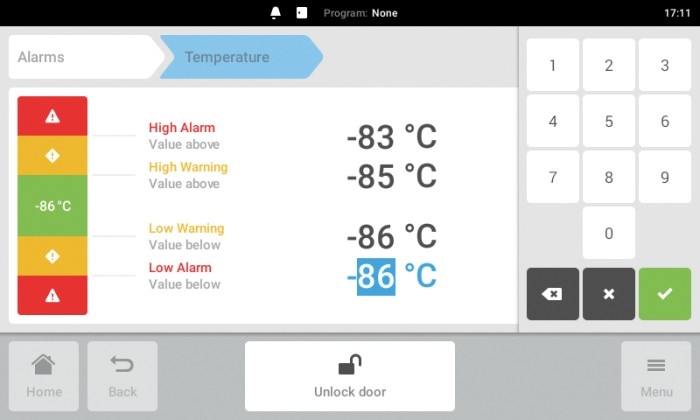

Monitoring/ alarm systems

Every freezer is equipped with an internal temperature probe to control the temperature within the chamber. Based on that measurement, the freezer firmware controls the compressor system to adapt the temperature if necessary. The alarm system of the freezer is based on this internal temperature probe. For many freezers, you can define the limit for alarms, e.g. 3 °C below the set-point. That means, when the freezer is set for -80 °C, the alarm will start at -77 °C. Be aware, the more often the freezers is opened, the more temperature buffer should be included for the alarm. Otherwise, the alarm system will be triggered all over the day.The local alarm is generated by integrated warning lamps and audio warnings at the freezer.

If the freezer is connected to a building management system (BMS), the alarm is transferred to a central alarm control unit. This finally results in that infamous call at 3 a.m. by the guard informing you about your freezer alarm.

Especially in pharmaceutical environments, a second, independent, temperature monitoring/ alarm system is more and more requested. These independent temperature measurements are based on a completely independent system with external power supply, backup battery, and messaging system. The independent temperature probe should be installed in a proper way in the middle of the freezer compartment, in close neighborhood to the internal freezer probe.

Read more

Read less

Back-up systems

The biggest threat to your samples is a break down of your freezer. This can be caused by a simple power outage or a failure of the freezer cooling system itself. In some situations, a backup freezer can be a solution. But that unit needs power and a person who is transferring all racks with samples from the broken freezer to the backup freezer.As midterm solution, you may use an automatic back-up system to save your samples for some hours within the broken freezer. The back-up system produces cold temperatures within the freezer in case of an emergency. How does it work?

When liquid is vaporized to gas, evaporation cold is generated. The back-up system injects the pressurized liquid into the freezer. At that very moment, the liquid is expanded to gas status and the temperature within the freezer chamber drops due to the evaporation cold.

In principle, there are two systems available: Based on CO2 or based on LN2. CO2 can keep the temperature between -50 °C and -70 °C, depending on the injected volume. Based on LN2, the temperature within the freezer can be kept at -85 °C. The back-up systems are equipped with batteries to enable injections even at general power outages. They have a separate temperature probe within the freezer and a temperature threshold. The temperature probe as well as the injection tube are installed via the two access ports which are located at the top of the freezer. When the temperature probe detects an exceeding of the pre-defined temperature threshold, the backup control unit automatically opens the valve for the CO2 or LN2.

Injection times and thereby supply of cold air depends on the size of the dedicated gas bottles. The filling degree of the bottle needs to be checked on a regular pattern.

Read more

Read less