CellXpert® C170i - Cell Culture Incubator

Product Information

Cell culture incubator CellXpert® – Culture of TomorrowAre you looking for a 170 L cell culture incubator that is easy to clean and delivers optimized growth conditions, even for your sensitive cells? The GMP/GLP-compatible CellXpert C170i is more than just that. It also helps to reduce the running costs of your lab significantly and it provides flexibility for different future lab setups and applications – with many in-field upgradeable options.

CellXpert C170i

You will find additional download material at the bottom of this page

Products (20)

Services (11)

Accessories (11)

Spare Parts (7)

VisioNize (5)

Catalog no.

6731000012

|

Catalog no.

6731000052

|

Catalog no.

6731000352

|

Catalog no.

6731001052

|

Catalog no.

6731001092

|

Catalog no.

6731000322

|

Catalog no.

6731001022

|

Catalog no.

6731000122

|

Catalog no.

6731000222

|

Catalog no.

6731001042

|

Product Information

Technical Data

Features

Product Information

Today's cell culture requires more than technical solutions for optimized growth conditions and efficient contamination prevention.

The CellXpert® CO2 incubator family are the first cell culture incubators engineered and produced by Eppendorf in Hamburg, Germany. They were designed with the needs of modern industrial and academic cell culture labs in mind - to reduce time-to-market or publication with minimal efforts and resources. The development of the CellXpert® family integrates e.g. the learnings from decades of using standard fan-assisted cell culture incubators in cell culture labs. They are the perfect partner for demanding applications like assay-development or culture of stem cells, primary cells or tissues. Read more and see more videos and papers below.

Learn more: Video – Easy cleaning and reliable contamination prevention with CellXpert CO2 incubators

Main features

• Certified 180 °C sterilization routine: incl. downloadable protocol

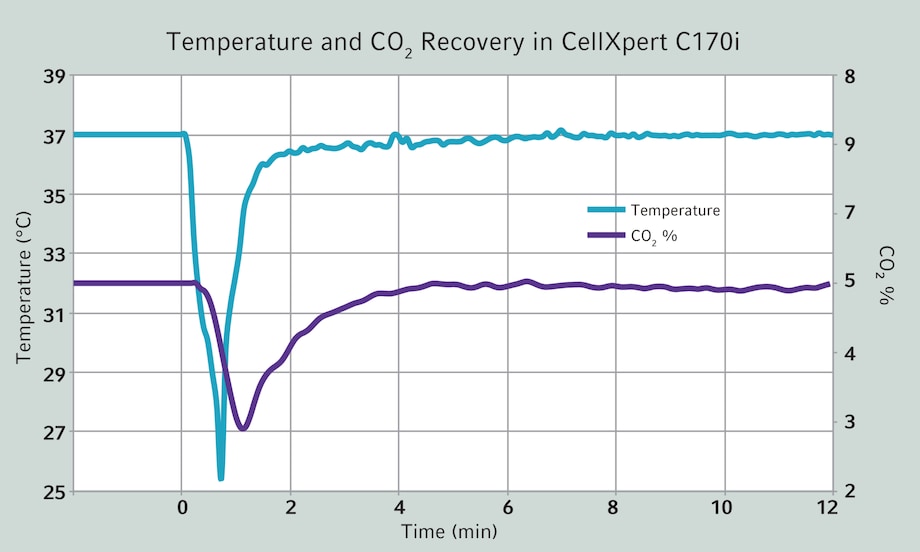

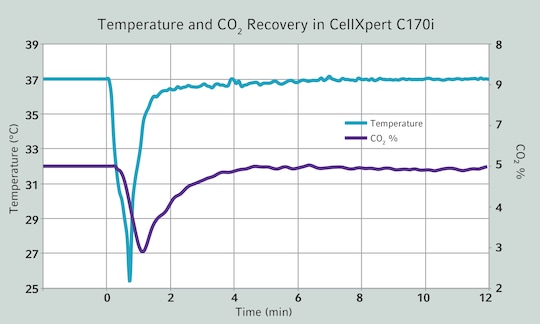

• Uniform atmosphere: Dual-channel IR-sensor (no TC-sensor), temperature uniformity verified (ISO 12880:2007-05), temperature and CO2 recovery after door opening < 5 min

• Effective contamination protection: Removable water tray for safe and easy weekly cleaning and refill according to good cell culture practice

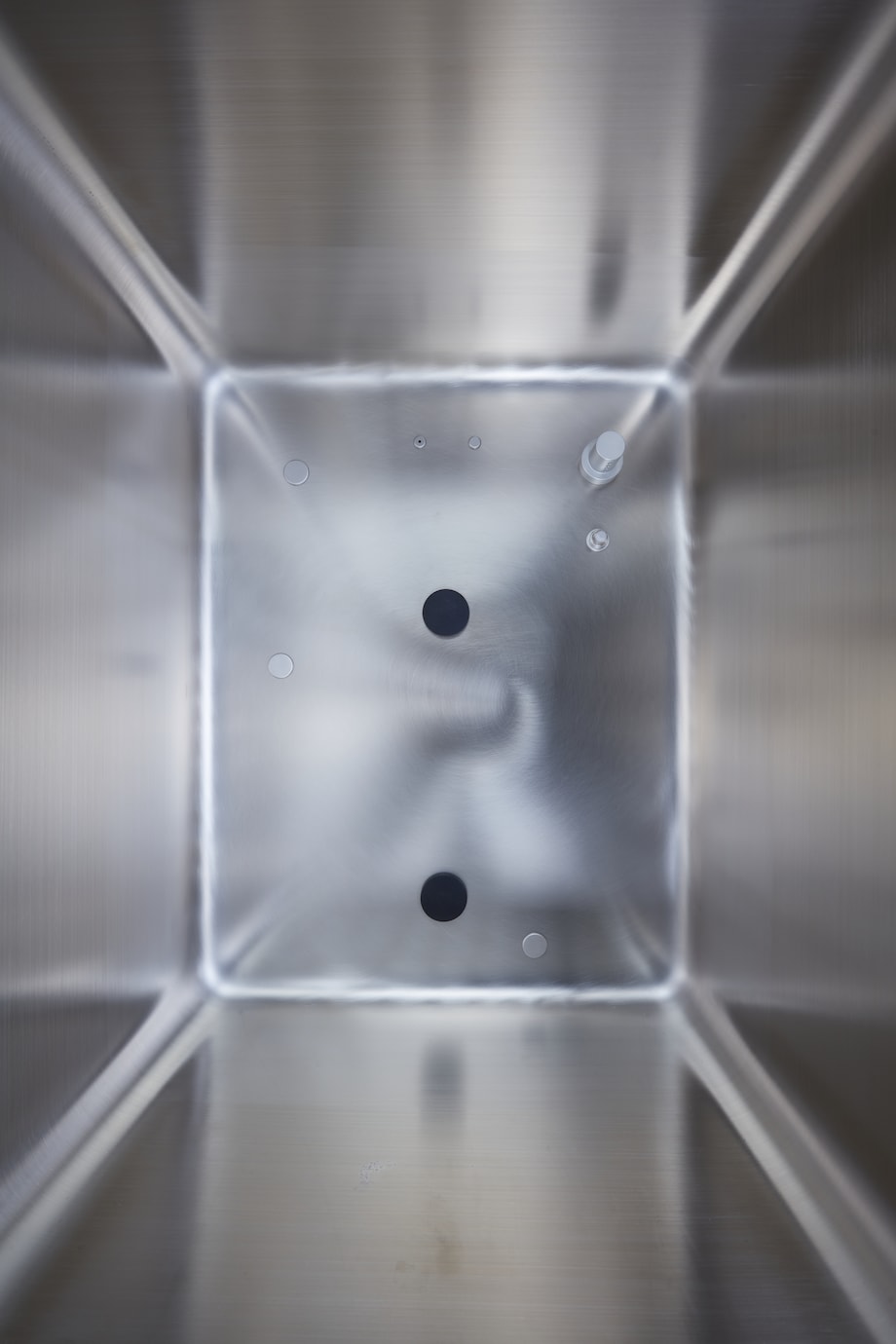

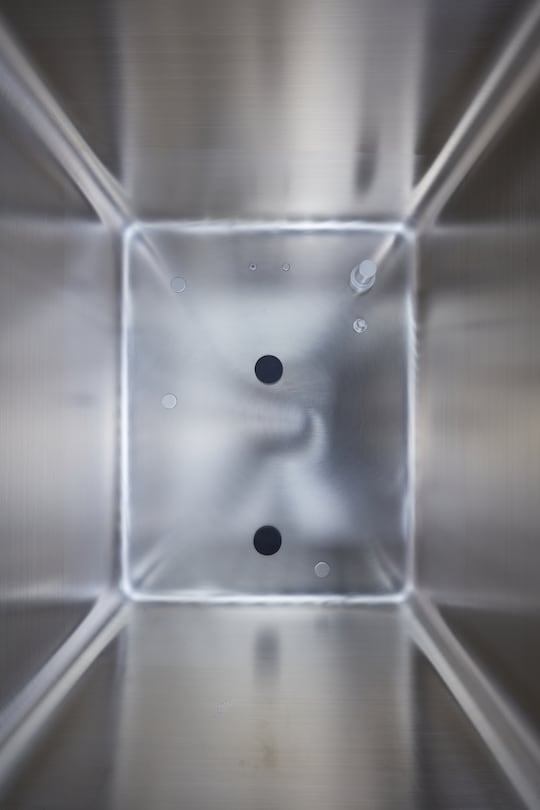

• Easy cleaning: Stainless-steel chamber without seams, fan, ducts, covers etc.

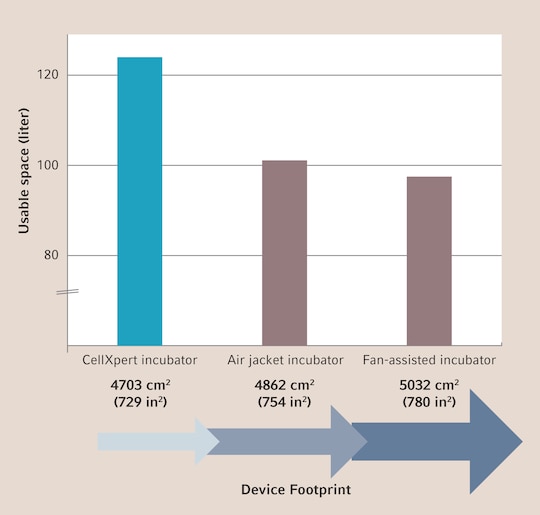

• Save money: Up to 25 % more usable space by fanless design, 4 shelves (max. load per shelf: 10 kg/22 lbs) + 2 access ports included, no costly internal expendable parts like fan-associated HEPA-filters that require bi-annual replacement

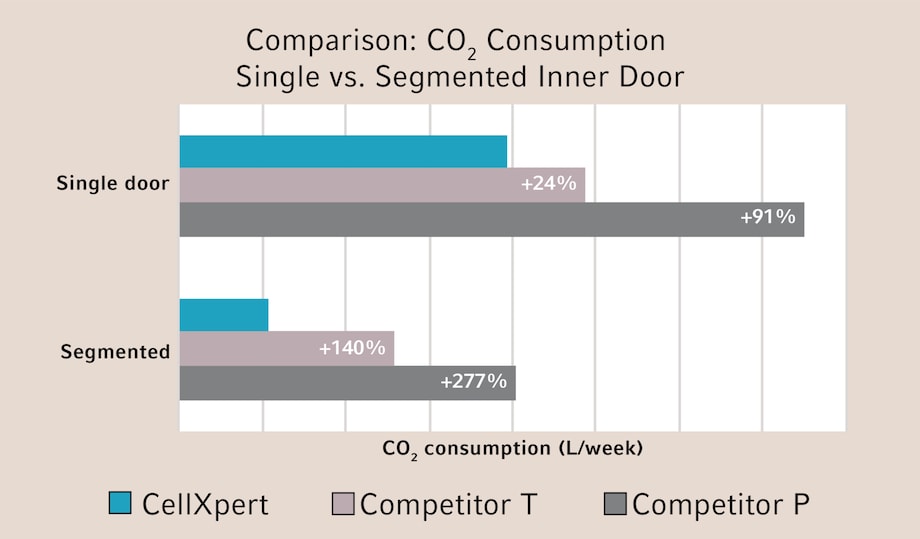

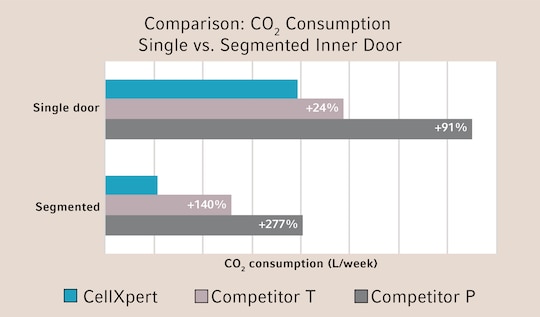

• Low gas consumption: <1 L CO2/24 h (5 % CO2, w/o door opening)

• Retrofit options: O2 control, door handle position, rH/water level monitoring, segmented inner doors

• GMP/cleanroom-compatible: ISO class 4/Grade A cleanroom certified (ISO 14644-1), cytotoxicity test of materials: passed (ISO 10993-5:2009), customized tasks and alerts, user management, IQ/OQ GxP Service and more

Easy cleaning, reliable contamination prevention

Prevention of lab downtime and sample loss is essential for you to deliver cell culture results in time? You cannot afford to spend too much time and money on standardized cleaning of your cell culture incubator, documentation or on changing costly, non-sterilizable, fan-associated HEPA filters?

Contamination prevention with CellXpert® CO2 incubators follows a simple concept: If it's easy to do, it's more likely to get done.

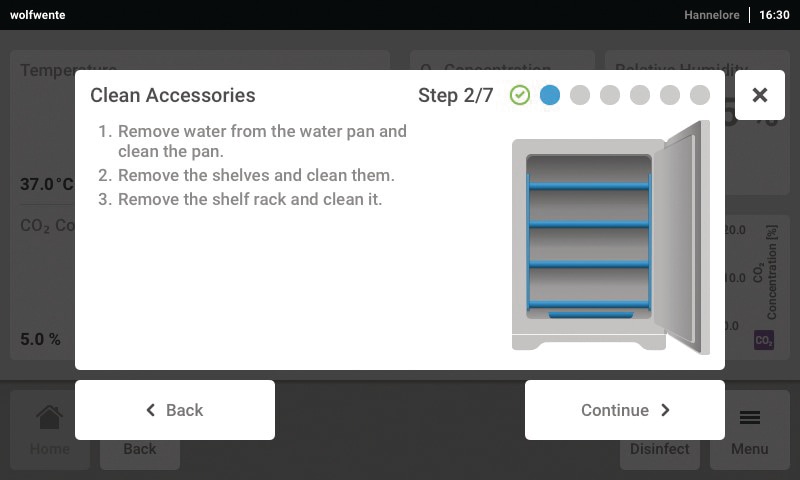

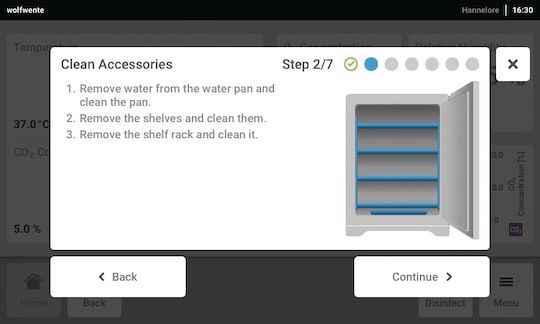

• 180 °C high temperature disinfection with illustrated step-by-step instructions on screen and downloadable performance protocol for standardized procedures

• Minimal internal incubator parts removed in 40 s and wiped quickly

• Nowhere to hide for contaminants and cleaned fast: Smooth, seamless incubator chamber

• Fanless design

• No non-sterilizable fan-associated HEPA filters that can become potential contamination sources

• Options for copper and segmented inner doors for additional protection

Learn more: Video – Easy cleaning and reliable contamination prevention with CellXpert CO2 incubators

Fanless incubator design = No costly, fan-associated internal HEPA filters

One of the strongest contamination protectors in the CellXpert is the fanless design. It effectively reduces the spread of airborne contaminants and therefore eliminates the need for fan-associated internal HEPA filters.

Generally, HEPA filter cartridges are heat-sensitive and need to be removed before starting an HTD. For reinstallation of the HEPA filter (that traps particles, but does not destroy them), extended door opening and reaching inside the clean chamber a full arm´s length is necessary. These factors pose a high risk of introducing new contaminants into the incubator.

The CellXpert cell culture incubator reduces significant recurring costs for fan-associated HEPA filters that must be replaced regularly – while offering strong contamination protection.

Do you need a fan for fast atmosphere recovery after door opening and spatial homogeneity?

Fanless cell culture incubators have always been a solid choice for customers with a high demand for easy cleaning, effective contamination prevention, and protection from vibrations and air turbulences. Also, the reduced number of internal parts compared to fan-assisted cell culture incubators (e.g. ducts, filters, fan itself etc.) is advantageous regarding optimal use of space inside. In the past, however, fast atmosphere recovery after door opening and spatial homogeneity compared to fan-assisted cell culture incubators have always been a challenge.

The new CellXpert® solves this former disadvantage by implementing various technologies: multiple, independent temperature sensors (see section below), as well as advanced microprocessor and gas control.

The result: The CellXpert® cell culture incubators can easily compete with fan-assisted devices regarding recovery and spatial homogeneity of CO2 and temperature (see below).

Optimized cell growth conditions for reproducible results

You cannot afford to spend time, money, or valuable source material on additional experiments due to insufficient reproducibility? You can reduce time-to-market or time-to-publication with CellXpert® cell culture incubators by standardized procedures and:

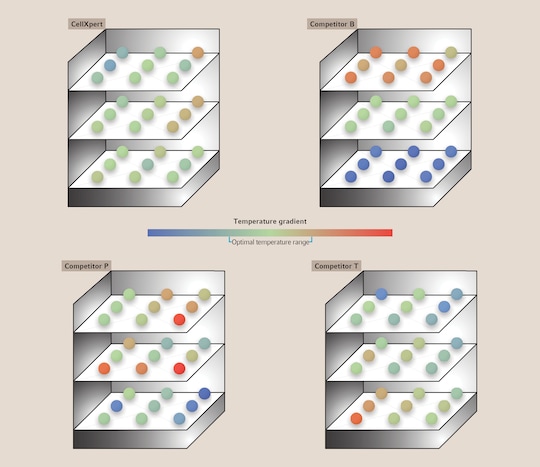

• Precise temperature uniformity throughout the incubator chamber, verified at 27 spots inside based on German Norm DIN 12880

• Fast gas and temperature recovery < 5 min without setpoint overshoot

• Protection from vibrations and turbulence with fanless incubator design, so cell culture vessels can also be located on the top shelf

• State-of-the-art dual channel IR-sensor for CO2 control and platinum-coated ZrO2 sensor for variants with O2 control (both sensors are high temperature resistant)

• Dedicated IQ/OQ and Eppendorf service contracts

Multiple temperature sensors at various locations inside the incubator

To accurately compare cell growth in vessels at different locations inside the incubator, the temperature needs to be highly uniform. Together with advanced microprocessor control, this is achieved in CellXpert® cell culture incubators by replacing the traditional configuration of one or two temperature sensors (the second almost always just used to control for overtemperature) with multiple, independent sensors in different locations. The effectivity of this novel approach has been verified by measuring the temperature deviation among 27 spots inside the incubator based on the German Norm DIN 12880 – and far exceeding the requisite specification.

Does it matter where you put the vessels inside your cell culture incubator?

Learn more: White Paper about CO2 incubator homogeneity

Do you cultivate cells on the top shelf of your fan-assisted cell culture incubator?

Afraid of vibrations or increased medium evaporation?

Have you ever experienced variations between cells grown in vessels on different shelves of your cell culture incubator, especially between the top shelf and others?

These differences can be caused by air turbulences that disrupt the protective micro-atmosphere above the medium. Air turbulence can be generated by fans used to circulate the atmosphere inside standard CO2 incubators. Additionally, uneven cell growth can occur because the fan may cause the vessels to vibrate – especially in the case of sensitive cells. These effects can be avoided with fanless CO2 incubators like the CellXpert. Air circulation via convection provides uniform temperatures, fast recovery, and conditions without the risks due to a fan. Enjoy peace of mind using the top shelf and use more valuable space.

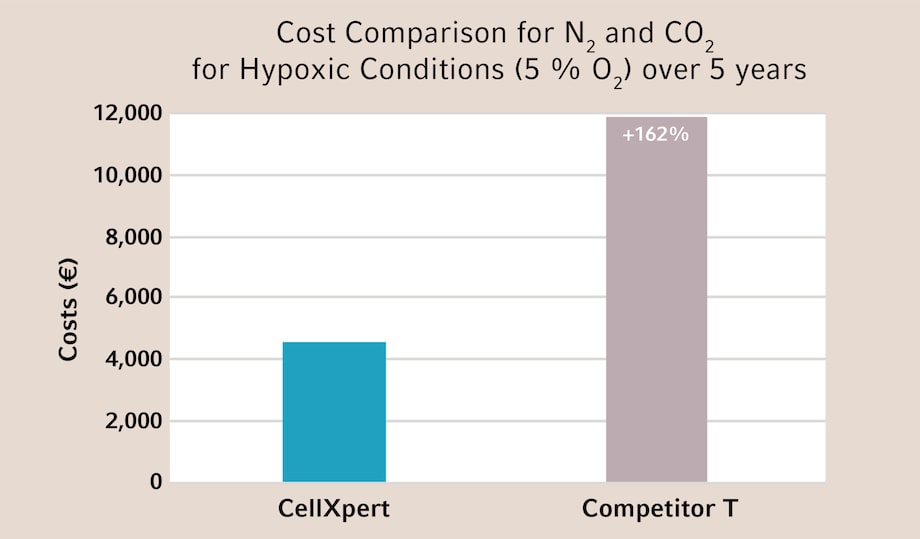

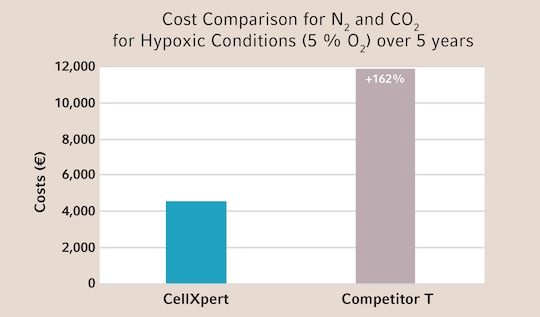

Save up to 8300 € / 9000 $ over five years and cell culture lab space

Did you know that running costs for a CO2 incubator easily exceed its purchase price over time?

Some costs are significant but not always obvious at first glance: regular replacement of fan-associated HEPA filters or UV lamps, loss of lab space because of low vessel capacity vs. footprint ratio, high incubator gas consumption, or lack of flexibility for future lab needs. Also, increased lab downtime risk and potential sample loss due to unreliable contamination prevention can add significant costs.

CellXpert® cell culture incubators provide answers to these challenges by:

• Saving lab space: Up to 25 % more usable space in a small footprint (no additional interior parts like fan, air ducts, HEPA filters etc.)

• Saving up to 1000 € / 1100 USD in five years - No internal expendable parts like fan-associated HEPA filters or UV lamps

• Significantly lower CO2 and O2 consumption by smart gas control

• Up to over 7300 € / 8180 USD less gas consumption in five years for low O2 experiments

• Get features you need at the time you need them – with many upgradeable options

• Long-lasting quality – Made in Germany

• Many features and accessories already included: 4 shelves, dual-channel IR-sensor for CO2 control (instead of TC-sensor), two access ports etc.

Learn more: White Paper - How to Save Money with CellXpert CO2 incubators

Stay flexible for the future of your cell culture lab

Will it become necessary to rearrange your cell culture lab, move it to a new location altogether or perform experiments under different atmospheric conditions?

Over an average incubator lifetime, a laboratory setup can change several times, especially in fast growing companies. Often, experimental demands also change over time. CellXpert® C170i cell culture incubators can be tailored according to changing needs. This reduces costs by upgrading features only when they become necessary. Enjoy peace of mind by knowing that your investment can be adapted to changing needs and requirements of your cell culture lab. Stay flexible for the future!

Upgradeable options:

• Door handle changeable in field from right <> left

• O2 control for hypoxic experiments (e.g. for stem cells or cancer research)

• Pre-installed access ports for in-incubator experiments with user-validated devices

• 4/8-segmented inner door

• Water level monitoring and relative humidity monitoring

Smart cultivation and easy documentation – with VisioNize®

Establish specific cell-conserving user habits in your lab and relieve yourself from the burdens of daily routines.

• VisioNize® touch interface for fast and continuous navigation

• Step-by-step wizard for standardized cleaning

• Filter and export performance charts, events, or HTD-protocols within seconds via Ethernet or front USB-ports

• Pre-installed and customer-programmed reminders, e.g. for performance of a disinfection cycle, cleaning, splitting cells, refilling the water reservoir, or performance checks with external sensors.

• Integrated alarm system to define critical values e.g. door-opening time or gas concentration that trigger a highly visible on screen and audible alarm

• SMS or email notifications by VisioNize notifications

• Set permissions and restrictions with on-board VisioNize® user management

• Remote Device Monitoring and Alert Notifications with VisioNize® Lab Suite

Efficient lab and device management with VisioNize® Lab Suite

Are you interested in monitoring your lab devices and receiving notifications e.g., for device alarms? A digital, connected lab offers even more.

Gain access to a modular range of digital services and choose what works for your lab. VisioNize Lab Suite offers everything you need as a Lab Manager or Scientist to get started to digitally manage your lab for increased sample security, compliance needs and maintenance management.

Chart your own course to digital lab excellence! Find out more

Reduce stress with the PhysioCare Concept®

Working in a cell culture lab is often associated with physical and psychological stress (e.g. working under time constraints, high noise and poor ergonomics; constant disinfection and care to avoid contamination; processing of many samples per day; and handling of various cell culture vessel types). This stress not only reduces your well-being and can lead to errors in the workflow, but could also contribute to illness in the long term. CellXpert® cell culture incubators were developed for more comfort and convenience in mind – with the Eppendorf PhysioCare Concept®:

• Unique magnetic closure concept and robust outer door handle

• Dual direction inner incubator door latch - simply pulled or turned to open, pushed or turned to close

• Almost silent operation

Downloads: CellXpert® C170i

Filter

Reset all