MENU

NL | EUR

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

- LabDays 2025

- ASIA LABEX: The Lab Show 2025

- Stem Cell Community Day 2025

- Nordic Life Science Days 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

- LabDays 2025

- ASIA LABEX: The Lab Show 2025

- Stem Cell Community Day 2025

- Nordic Life Science Days 2025

NL | EUR

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

Sorry, we couldn't find anything on our website containing your search term.

10 reasons to choose a pipetting robot for routine lab work

Dr. Stefanie Rösel Lab Academy

- Pipetting & Dispensing

- Efficiency

- Scalability

- Automation

- Liquid Handling Workstations

- Essay

Reformatting, plate multiplication, aliquoting, pooling, cherry picking, dilution curves or normalization – the daily business in labs. Honestly, tiring and often frustrating procedures: time-consuming, non-ergonomic, error-prone. In times of standardization, where efficiency, throughput, reproducibility and a responsible use of resources are mandatory, it's worth taking the step forward and thinking about automation. Let us show you why!

Reality check: what do pipetting robots do at all?

Pipetting robots are gigantic devices, complicated to operate and much too big? You need programming skills to get them running? Definitely not! Also known as liquid handlers or liquid handling systems, they are often small smart benchtop robots, which are capable to perform daily tasks directly at your workplace. Pipetting-intensive protocols are transformed into ready-to-run workflows requiring minimal interventions and setup time. You benefit from an increased throughput topped with an improved accuracy and a minimized risk of error. The easy-to-use systems boost your productivity by freeing you from routine lab work.

Automated liquid handling systems form the perfect basis for standardization!

Read more

Read less

1. Delegate your standard tasks

No more routine tasks to do by yourself: repetitive sample transfer between various source and destination vessels as from tubes to plates, concentrated “cherry picking” of individual samples, tedious plate multiplication or exhausting pooling from different samples according to various patterns.

No more routine tasks to do by yourself: repetitive sample transfer between various source and destination vessels as from tubes to plates, concentrated “cherry picking” of individual samples, tedious plate multiplication or exhausting pooling from different samples according to various patterns.

Read more

Read less

Figure 1: Automated liquid handling tasks over your routine pipetting

You can exactly reproduce your manual work steps! With only few clicks you can easily program your liquid handling steps in any desired order and number - even the most complex workflows! Simply combine the workflow elements as you would do with manual steps: reagent and sample transfer, tip mixing, heating, cooling, shaking, vacuuming, waiting steps, magnetic or vacuum separation. On top, you can simulate runs in silico to optimize your workflow, without losing consumables, reagents, samples, etc.

Automated liquid handling has a high flexibility and can be used for a wide application area.

Automated liquid handling has a high flexibility and can be used for a wide application area.

Read more

Read less

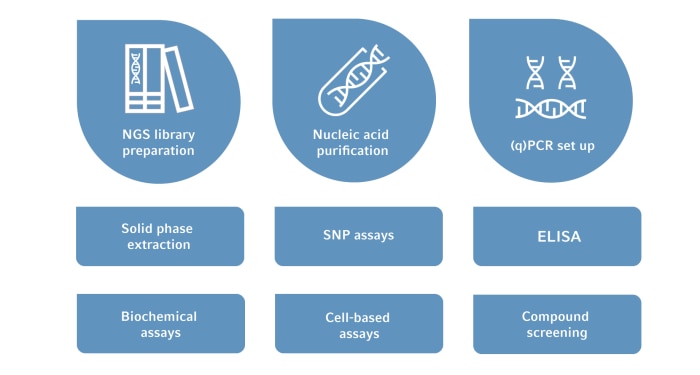

Figure 2: Typical application of automated liquid handling

2. Higher throughput in less time

Compared to manual pipetting, you can process up to 96 samples simultaneously with high speed. Also, batches with a multitude of samples (e.g. blood, tissues) can be handled. Workflows get significantly streamlined, so that you can run entire protocols in less time.

3. Error-free

Common error sources are practically eliminated. Your benefits: improved consistency, better precision and accuracy, topped with less sample loss and reagent usage. Some background: inter-user or inter-run variability and errors associated with manual pipetting potentially compromise results and lead to poor data quality and costly re-runs. The issues range from inconsistent dilution techniques between samples, differences between the pipetting of multiple lab technicians, variation across the day to differences in concentration across assays. Not to forget, the smaller the volume, the larger and the more significant the error!

4. Reproducibility & standardization

Less errors, less repetitions of failed experiments, increased throughput and efficiency increase the reproducibility and pave the way to standardization.

5. Automated documentation

You get rid of tedious documentation! The automated documentation tracks comprehensively every detail for each run: sample, barcode, operator, time, type of procedure, position of sample in a plate from origin to destination, volumes, and many more.

6. Increased productivity

The automated and streamlined workflow significantly reduces your hands-on time and allows for maximum walk-away time. This frees you up to spend more time to other sophisticated work such as focusing on the analysis and interpretation of results.

7. Contamination prevention

A multilevel contamination prevention protects precious samples and valuable regents, ensured by many features like contact-free dispensing, autoclavable tools, sterile filter tips, HEPA-filter and UV-sterilization. In contrast to manual liquid handling, the system is completely closed for maximum safety.

8. User protection

The contamination prevention features also protect the user from biohazardous substances.

9. “Body & mind protection”

Enjoy peace of mind as your pipetting robot relieves you from the extreme manual handling stress. The strain of performing repetitive manual tasks relaxes your muscles and joints. As a highly qualified specialist, you can be glad that tiresome tasks belong to the past and you can devote yourself to the really ambitious things.

10. Ease of use

Compared to manual pipetting, you can process up to 96 samples simultaneously with high speed. Also, batches with a multitude of samples (e.g. blood, tissues) can be handled. Workflows get significantly streamlined, so that you can run entire protocols in less time.

3. Error-free

Common error sources are practically eliminated. Your benefits: improved consistency, better precision and accuracy, topped with less sample loss and reagent usage. Some background: inter-user or inter-run variability and errors associated with manual pipetting potentially compromise results and lead to poor data quality and costly re-runs. The issues range from inconsistent dilution techniques between samples, differences between the pipetting of multiple lab technicians, variation across the day to differences in concentration across assays. Not to forget, the smaller the volume, the larger and the more significant the error!

4. Reproducibility & standardization

Less errors, less repetitions of failed experiments, increased throughput and efficiency increase the reproducibility and pave the way to standardization.

5. Automated documentation

You get rid of tedious documentation! The automated documentation tracks comprehensively every detail for each run: sample, barcode, operator, time, type of procedure, position of sample in a plate from origin to destination, volumes, and many more.

6. Increased productivity

The automated and streamlined workflow significantly reduces your hands-on time and allows for maximum walk-away time. This frees you up to spend more time to other sophisticated work such as focusing on the analysis and interpretation of results.

7. Contamination prevention

A multilevel contamination prevention protects precious samples and valuable regents, ensured by many features like contact-free dispensing, autoclavable tools, sterile filter tips, HEPA-filter and UV-sterilization. In contrast to manual liquid handling, the system is completely closed for maximum safety.

8. User protection

The contamination prevention features also protect the user from biohazardous substances.

9. “Body & mind protection”

Enjoy peace of mind as your pipetting robot relieves you from the extreme manual handling stress. The strain of performing repetitive manual tasks relaxes your muscles and joints. As a highly qualified specialist, you can be glad that tiresome tasks belong to the past and you can devote yourself to the really ambitious things.

10. Ease of use

Read more

Read less

An automated liquid handling system (if chosen the right one) is very easy to use. The simple software can be implemented quickly from everyone. User-friendly computer interfaces with pre-optimized commands and step-by-step guidance make programming and operation intuitive, quick and easy. The small instrument footprint frees up bench space.

Pave the way for standardization with improved accuracy and reproducibility as well as increased productivity!

Pave the way for standardization with improved accuracy and reproducibility as well as increased productivity!

Read more

Read less