Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

Monoclonal Antibody Process Development

显示更少

Originally, for monoclonal antibody production mAb-producing cells (hybridomas) were generated by fusing immortal myeloma cells with antibody-producing B cells. Today, Chinese Hamster Ovary (CHO) cells are often used as an expression system. Antibody production in bacteria or yeast offers greater speed, however there are challenges associated with glycosylation. Find out more about bioprocessing methods for mAB generation in our ebook!

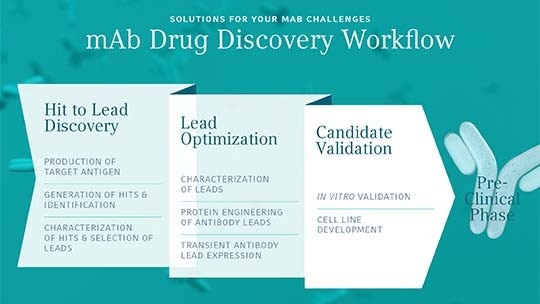

mAB discovery workflow

Antibody development is not without its challenges. Research teams are under increasing pressure to produce specific, high-quality therapeutic treatments within ever-tighter time and budget restrictions. As such, it is essential to optimize each step of the monoclonal antibody production process, from transfection, to clone selection, to process control and scale-up. From choosing candidate cell lines to scale-up, Eppendorf can help you to maintain a competitive edge by providing the tools, expertise, and knowledge needed to improve and regulate antibody yield and quality.

Choose the right bioreactor system for monoclonal antibody process development

显示更少

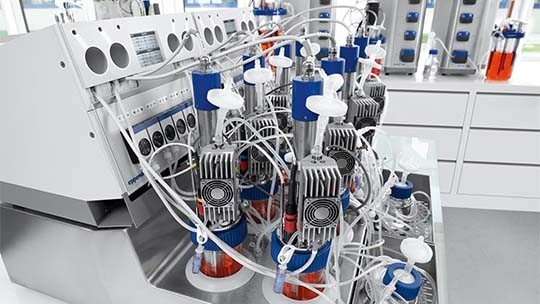

Parallel, small-scale bioprocess systems

Parallel small-scale bioreactor systems like the DASbox® Mini Bioreactor System support customers in implementing QbD principles in their development phase. These high-throughput bioreactor systems are designed for parallel cultivations, making them ideal for experimental design, parallel comparison studies and downscaling experiments.

Single-use bioreactors

Eppendorf offers a scalable portfolio of single-use bioreactors , for seamless process scale-up from R&D labs to pilot production facilities.

- The BioBLU® c Single-Use Bioreactors cover a working volume range of 100 mL to 40 L. These are rigid wall, stirred-tank bioreactors, which are compatible with various Eppendorf bioreactor control systems, including the DASbox® Mini Bioreactor System , the SciVario® twin , and the BioFlo® 320 bioreactor control system .

- For scale-up to larger volumes Eppendorf offers the BioFlo® 720 bioreactor control system , which is compatible with Thermo Scientific™ HyPerforma™ 5:1 single-use bioreactors with a working volume up to 2000 L.

From small scale to pilot production scale

Bioprocess scale-up from small development scale to pilot scale is a fundamental part of process development in the biopharmaceutical industry. Eppendorf provides upstream bioprocess solutions that make it simple to scale up your antibody production. Small and bench-scale bioreactors, including the DASbox® Mini Bioreactor System and the BioFlo® 320 bioreactor control system are compatible with glass and single-use bioreactors and can be used with a range of volumes from 0.25 - 40 L. For larger processes, the BioFlo® 720 can handle much larger working volumes of up to 2000 L.The BioFlo® 320 and 720 bioreactor control systems have an integrated Scale Up Assist software to simplify the workflow and calculations necessary for scale up.

Software

Eppendorf bioprocess software including DASware® control and BioCommand® can be implemented into bioreactor control systems for advanced process monitoring and control in monoclonal antibody production. They provide real-time insights to help improve product quality, including process automation features, intelligent recipe management, and integrated report generating capabilities. Eppendorf bioprocess software facilitates the integration of process analytical technology (PAT) .

How our customers use our products

显示更少