菜单

CN | CNY

CN | CNY

Sorry, we couldn't find anything on our website containing your search term.

Sorry, we couldn't find anything on our website containing your search term.

DASware® control

DASware control single

DASware control

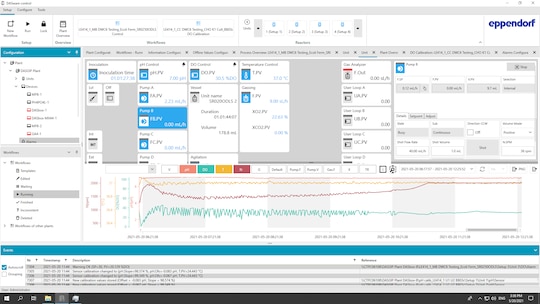

SCADA Software for advanced process monitoring, control, and data logging - for parallel cultivation with individual control of each bioreactor

SCADA Software for advanced process monitoring, control, and data logging - for parallel cultivation with individual control of each bioreactor

产品信息

DASware control is the bioprocess SCADA software at the heart of all Eppendorf small and bench-scale bioreactor systems and our large- scale single-use system. It enables individual monitoring and control of up to 24 bioreactors in parallel, process automation, and advanced data analysis, providing maximum performance from experimental design to result.您可以在以下网址找到其他下载资料本页面底部

产品 (5)

附件 (1)

5 产品

目录编号

78600189

|

|

|

显示更多产品

已添加到您的购物车

产品信息

特征

产品信息

Bioreactor Systems and Software Solutions – Orchestrated for Bioprocess Control, Automation, and Analysis

DASware control is the central bioprocess software solution from Eppendorf. Beyond bioprocess monitoring and control, it enables the seamless integration of bioprocess systems, control software, data analysis tools, and automation solutions to form a complete upstream bioprocessing solution.

Key benefits

• Parallel process monitoring and control.

• Reduced complexity due to the use of one central software solution.

• Easy integration of devices such as third-party sensors.

• Simplified data sharing and improved data analysis through seamless connection to BioNsight® cloud software.

Compatible controllers

• Bioprocess control software for the DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems.

• Optional SCADA software for SciVario® twin, BioFlo® 120, BioFlo 320, and BioFlo 720 bioprocess controllers that offers advanced features for process control, such as the integration of external sensors and scripting of feedback loops.

• Enables seamless integration of selected controllers with the Bioprocess Autosampler.

DASware control is the central bioprocess software solution from Eppendorf. Beyond bioprocess monitoring and control, it enables the seamless integration of bioprocess systems, control software, data analysis tools, and automation solutions to form a complete upstream bioprocessing solution.

Key benefits

• Parallel process monitoring and control.

• Reduced complexity due to the use of one central software solution.

• Easy integration of devices such as third-party sensors.

• Simplified data sharing and improved data analysis through seamless connection to BioNsight® cloud software.

Compatible controllers

• Bioprocess control software for the DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems.

• Optional SCADA software for SciVario® twin, BioFlo® 120, BioFlo 320, and BioFlo 720 bioprocess controllers that offers advanced features for process control, such as the integration of external sensors and scripting of feedback loops.

• Enables seamless integration of selected controllers with the Bioprocess Autosampler.

生物工艺控制系统功能强大

• 高效:传感器并行校准,智能配方管理,脚本自动化进一步提升。

• 性能:同时运行最多8/16/24个反应罐,功能强大的制图工具,以及先进的数据管理。

• 灵活:可配置视图与用户自定义功能;现场软硬件更新

• 可靠:用户管理与数据完整性,事件日志和警报功能

• 监管标准:如需符合21 CFR Part 11与EudraLex Volume 4 Annex 11规定的生物工艺控制软件,请深入了解DASware control plus

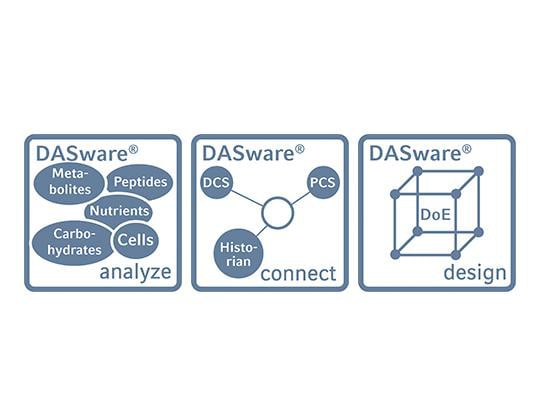

使用DASware软件套件扩展功能

DASware design、analyze和connect是DASware control SCADA软件的可选附加组件。

• 通过全因子DoE(实验设计)生成器或通过第三方DoE工具导入DoE设计,应用实验设计理念。

• 无缝集成外部实验设备至生物反应器,实现工艺自动化和反馈控制回路。

• 集成至工艺控制系统和企业历史记录,实现在全公司范围内访问所有相关生物工艺数据。

数据就在那里

生物工艺数据可以从 DASware control 无缝转移至BioNsight cloud软件。

• 实现远程监控和分析。

• 实现跨设备、跨运行和跨站点数据情境化。

• 为人工智能分析做好数据准备。

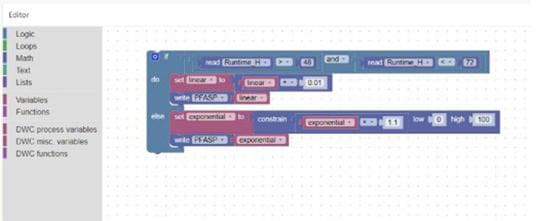

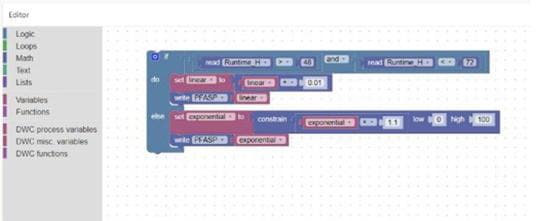

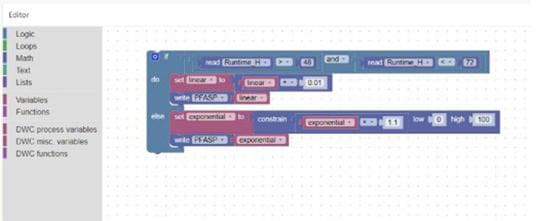

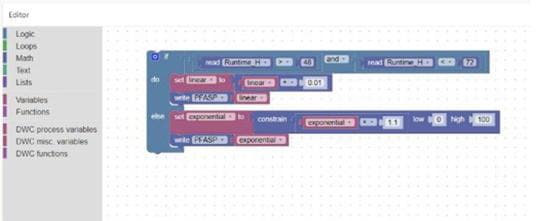

利用图形化编程轻松定制工艺控制

• 操作简单:采用拖放界面,用户可通过可视化链接功能块创建和修改工作流程,比传统的脚本撰写和编码更加简单。

• 提高准确度:可视化工作流程能够帮助用户及早发现逻辑或排序错误,最大限度减少工艺中断、提高整体准确度。

• 访问便捷:用户可快速学习和部署工作流程,提高运行效率、加快对工艺变更的响应速度。

• 透明:自动记录所有变更,促进合规,同时保存修改记录,便于后续审计。

阅读更多

阅读更少

特征

- Parallel process control with individual control of each vessel: DASbox Mini Bioreactor System: up to 24 vessels, DASGIP Parallel Bioreactor Systems: up to 16

- 无缝集成 SciVario twin与BioFlo系统(最多8个控制器)以及BioFlo 720(1个控制器)

- Integrated batch functionality for process and recipe management

- Ideally suited for Design of Experiments (DoE)

- Parallel calibration and cleaning procedures

- Customized views and user-defined functions

- Automated data export, reporting and chart creation for Microsoft® Excel®

- Professional database with managed access (Postgre SQL Server)

- OPC communication for easy integration with third party-equipment using DASware connect and DASware analyze

- Integrated analysis of offline values, online calculated values, and alarm notification

- IQ/OQ package available