메뉴

KR | KRW

KR | KRW

Regulatory info

Regarding suitability of Eppendorf bioprocess equipment for the production of food, please reach out to your Eppendorf sales representative.

Read more

Read less

Bioprocessing for Modern Food

The food industry is facing a revolutionary transformation as emerging production technologies offer more plant-based and animal-free food alternatives. In response to growing environmental and consumer concerns, there is increasing interest in food production strategies that reduce the issues related to livestock - from pollution and deforestation to antimicrobial resistance and concerns regarding poor animal welfare.

At the heart of this transformation stands the bioreactor, which enables many different ways of food production. For example, as one of the oldest processes of food production, fermentation is already utilized to produce animal products such as milk, cheese, and yoghurt using bacteria. However, an additional path towards conventional meat production alternatives is rapidly developing, with the potential to improve animal welfare and the environmental impact, while still coming from livestock muscle tissue. This new alternative is the creation of cultured meat from mammalian stem cells.

At the heart of this transformation stands the bioreactor, which enables many different ways of food production. For example, as one of the oldest processes of food production, fermentation is already utilized to produce animal products such as milk, cheese, and yoghurt using bacteria. However, an additional path towards conventional meat production alternatives is rapidly developing, with the potential to improve animal welfare and the environmental impact, while still coming from livestock muscle tissue. This new alternative is the creation of cultured meat from mammalian stem cells.

Read less

Discover the world of lab grown meat and how to produce it in bioreactors in our ebook "Bench to burger: The future of food from the lab".

What is cultured meat?

Cultured meat is genuine animal meat that is produced by cultivating animal cells directly to eliminate the need to raise and farm animals for food. Cultured meat is made of stem cells taken from an animal that differentiate into the skeletal muscle, fat, and connective tissues that make up meat products.

A general workflow from stem cell to product will involve the following steps:

A general workflow from stem cell to product will involve the following steps:

- 1. Collecting and storing animal stem cells. The cells are obtained by a harmless biopsy.

- 2. Growing stem cells in a bioreactor to achieve large-scale volumes. Bioreactors allow for maximum growth by creating and maintaining an optimal growth environment.

- 3. Using a combination of scaffolding and chemical signals to provide structural support and directed differentiation of cells into the desired meat product.

Read less

Get insights into the potential of lab grown meat through our application expert!

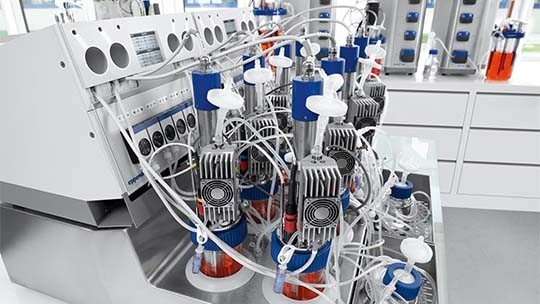

Eppendorf solutions to produce food in the lab

Efficient bioprocesses are central to the industrial production of modern food. Eppendorf offers scalable bioprocess solutions:

- Cultivation of stem cells, mammalian cell lines, and microorganisms

- Working volumes from 65 mL to 2,400 L

- Flexible hardware and intuitive software for process monitoring, control, and analytics

- Reusable and single-use bioreactors: Most Eppendorf bioprocess systems are compatible with glass or stainless-steel and single-use vessels, depending on the user’s need. Reusable vessels help reducing consumable costs, single-use vessels facilitate a faster turn-around.

Read less

Customer stories

Find out more about bioprocessing and the use of our products in the food and feed industry.

Read less