MENÚ

ES | EUR

ES | EUR

-

- Centrífugas de sobremesa

- Centrífugas de suelo

- Centrífugas refrigeradas

- Microcentrífugas

- Centrífugas multiuso

- Centrífugas de alta velocidad

- Ultracentrífugas

- Concentrador

- Productos IVD

- High-Speed and Ultracentrifuge Consumables

- Tubos de centrífuga

- Placas de centrífuga

- Gestión de dispositivos

- Gestión de muestras e información

-

- Pipeteo manual & dispensación

- Pipetas mecánicas

- Pipetas electrónicas

- Pipetas multicanal

- Pipetas de desplazamiento positivo y dispensadores

- Pipeteo automatizado

- Dispensadores de botella

- Controladores de pipeta

- Puntas de pipeta

- Consumibles de automatización

- Accesorios para dispensadores y pipetas

- Accesorios de automatización

- Servicios para dispensadores y pipetas

No se han encontrado resultados

Sugerencias de búsqueda

Grass Paper: The Green Way to Produce Paper and Cardboards

Dr. Kerstin Hermuth- Kleinschmidt

We are all asked to contribute to make the world more sustainable. A manufacturer, for example, can continuously work on new solutions, ideas, and reconsider processes and operations.

What are a manufacturer’s environmental impacts? Besides the production, transport and packaging have a relatively high environmental impact. Regarding packaging, cardboards and folding boxes are often the material of choice. But even with recycled cardboard, a certain amount of virgin wood fiber is still needed to produce it – which means that trees have to be felled. Is there a way to make these wood fibers obsolete?

Creapaper GmbH, The Grassfiber Company, situated in Germany, is creating new methods and uses grass fibers as a raw material to produce paper and cardboards [1].

Let’s take a closer look at what grass paper is and how it compares to other materials from an environmental perspective.

The most common alternative to paper made from fresh fibers is the use of recycled paper - after all, a cellulose fiber can theoretically be reused up to six times.

The additional positive aspect is that up to 60% less energy and up to 70% less water is used to produce recycled paper [3]. In 2018, waste paper was used for 76% of all paper produced in Germany. In figures, this is an impressive 17.2 million tons of recycled paper [4].

But even when using waste paper fibers to produce recycled paper, a certain amount of fresh fibers is still required, because with each recycling process the wood fibers are shortened and these shortened fibers must be replaced by longer, fresh fibers. Deforestation continues, even if at a reduced rate.

Isn’t there a way to replace these wood-based fibers and make the paper production more eco-friendly? This was the question that Uwe d'Agnone, founder of Creapaper, asked himself in 2014.

Many plants contain the basic material cellulose – just think of the Egyptians who wrote on papyrus. Newer paper developments experiment with hemp or bamboo. The idea was to replace fresh fibers from wood with grass fibers. Both materials contain pulp, the basic ingredient for paper. But grass has 75% less lignin and resin as wood, so it should be much easier to liberate the pulp. And is grass not growing everywhere?

The production process of grass paper is easy in comparison to wood-based paper production. Starting material is hay, dried grass which has been grown on regional agricultural compensation areas. The hay is being transported to the paper mill. There, it is cleaned, mechanically shredded, with the fibers being cut to a suitable length, and pressed to grass pellets. These pellets are then utilized directly in the paper production process without using any chemicals at all and resulting in the so-called “grass paper”. This final product is not 100% grass-based.

Creapaper GmbH, The Grassfiber Company, situated in Germany, is creating new methods and uses grass fibers as a raw material to produce paper and cardboards [1].

Let’s take a closer look at what grass paper is and how it compares to other materials from an environmental perspective.

How paper and cardboards are made today…

Today, the majority of our paper and cardboards are produced from either fresh fibers or recycled paper. The production process for paper and cardboard made from virgin wood fibers is very energy- and water-intensive. Cellulose fibers, which are the basis for paper products, must be separated from lignin, hemicellulose, and resins. For this purpose, the debarked wood in the form of wood chips is boiled in the sulphate process with sodium hydroxide and sodium sulphide at temperatures around 170 °C/175 °C, under high pressure for two to three hours. The paper then has to be bleached using chlorine dioxide or oxygen, hydrogen peroxide or ozone. [2] Not forgetting the transport of the raw material– often the source of high energy consumption and environmental pollution. The wood for paper production comes from all over the world and only a small part comes from Germany. This results in very long transport distances of several thousand kilometres. [3, 6]The most common alternative to paper made from fresh fibers is the use of recycled paper - after all, a cellulose fiber can theoretically be reused up to six times.

The additional positive aspect is that up to 60% less energy and up to 70% less water is used to produce recycled paper [3]. In 2018, waste paper was used for 76% of all paper produced in Germany. In figures, this is an impressive 17.2 million tons of recycled paper [4].

But even when using waste paper fibers to produce recycled paper, a certain amount of fresh fibers is still required, because with each recycling process the wood fibers are shortened and these shortened fibers must be replaced by longer, fresh fibers. Deforestation continues, even if at a reduced rate.

From wood to grass - a green idea is born: Grass paper

Isn’t there a way to replace these wood-based fibers and make the paper production more eco-friendly? This was the question that Uwe d'Agnone, founder of Creapaper, asked himself in 2014.Many plants contain the basic material cellulose – just think of the Egyptians who wrote on papyrus. Newer paper developments experiment with hemp or bamboo. The idea was to replace fresh fibers from wood with grass fibers. Both materials contain pulp, the basic ingredient for paper. But grass has 75% less lignin and resin as wood, so it should be much easier to liberate the pulp. And is grass not growing everywhere?

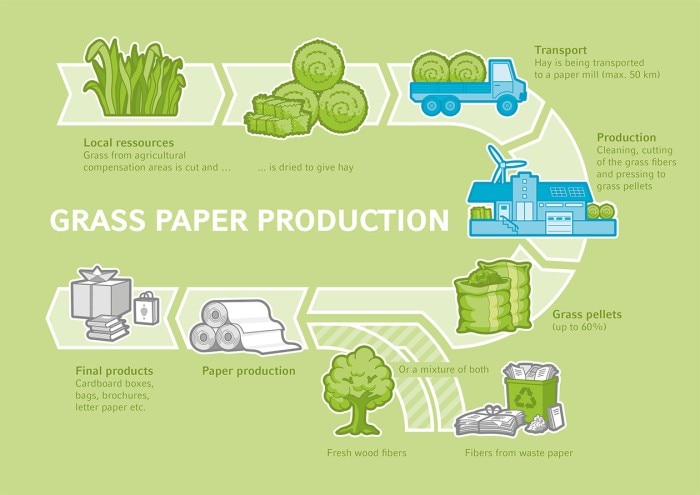

The production process of grass paper is easy in comparison to wood-based paper production. Starting material is hay, dried grass which has been grown on regional agricultural compensation areas. The hay is being transported to the paper mill. There, it is cleaned, mechanically shredded, with the fibers being cut to a suitable length, and pressed to grass pellets. These pellets are then utilized directly in the paper production process without using any chemicals at all and resulting in the so-called “grass paper”. This final product is not 100% grass-based.

Leer más

Leer menos

Grass paper is the term used to describe a pulp-based product which, apart from virgin fiber from wood or recycled paper, contains a significant proportion of grass fiber

Leer más

Leer menos

Depending on the product, the grass proportion is in the range of at least 10 % up to 60 %. Grass paper is very versatile: it can be used for folding boxes, packaging – ideal for food – brochures, or labels. It is recyclable like normal waste paper, but also compostable - and it does not hide its origin; instead, it can easily be recognized by its slightly green colour.

Leer más

Leer menos

See figure 1: Grass paper production

Grass paper on the test bench – the life cycle analysis

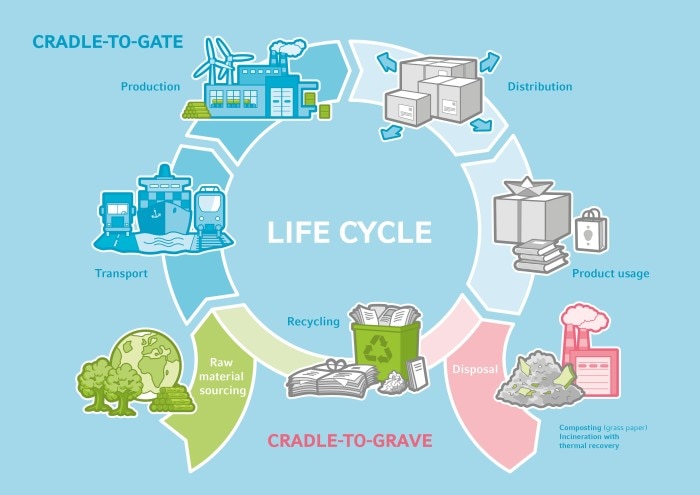

Grass paper seems to be the better alternative. Its production process without the use of chemicals and with short transport routes is environmentally friendly. Compared to paper made from primary fibers, the advantage seems obvious, but how big is the real advantage over production from virgin fibers in terms of resources saved? How does grass paper compare to recycled paper? Is it better to use meadows as a source of raw materials - after all, natural resources are being used and by mowing, aren’t we depriving insects of their food and habitat thus harming biodiversity? Grassland is also often fertilized which can lead to negative impacts like nitrate pollution, eutrophication in water bodies, or additional soil burden due to acidification. Many questions arise when approaching this topic.This is where the life cycle analysis comes into play. As the name says, this instrument traces the journey of a product from its sourcing to production, logistics, usage, and disposal, and sums up all the different environmental impacts during a products’ life. It helps to identify the biggest impacts, to uncover blind spots, to compare different scenarios, and to find the best solution.

Leer más

Leer menos

*The main steps for wood pulp production are shown here. The steps in the production of the grass-based pulp in a cradle to gate approach include the cultivation, transport and production of the grass pellets. (see figure 1)

A lot of data is gathered about the type (fossil or renewable) and amount of energy, the amount of used water, the released emissions during production and transport, or the impact of land use. And these are just some aspects out of a lot more data which are collected. In some cases, it is not possible to follow the whole grass life life cycle – grass pellets can end up in cardboards or birthday cards, they can be recycled or composted. Then it makes sense to have consider from cradle to gate and to compare only the impacts until a product leaves the factory gate.

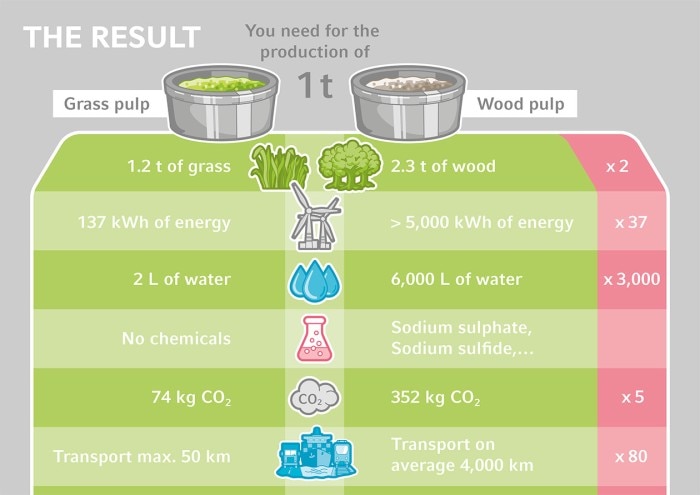

Thus, the monitoring and evaluation of the production process ensured that the "felt" advantage is backed up by data. The result of the comparison of grass pulp production against the production of wood pulp is quite impressive:

A lot of data is gathered about the type (fossil or renewable) and amount of energy, the amount of used water, the released emissions during production and transport, or the impact of land use. And these are just some aspects out of a lot more data which are collected. In some cases, it is not possible to follow the whole grass life life cycle – grass pellets can end up in cardboards or birthday cards, they can be recycled or composted. Then it makes sense to have consider from cradle to gate and to compare only the impacts until a product leaves the factory gate.

An ecological solution – right from the start

From the very beginning, all the aforementioned questions have been asked in the development of grass paper. Over the years, several life cycle assessments have been made to know the environmental impact and to make the right decisions, e.g. by using grass from regional, non-fertilized compensation areas [6,7,8]. It turned out that the cultivation method (unfertilized or “conventional”) has a significant impact on the ecological balance [9].Thus, the monitoring and evaluation of the production process ensured that the "felt" advantage is backed up by data. The result of the comparison of grass pulp production against the production of wood pulp is quite impressive:

Leer más

Leer menos

See figure 3: Comparison of the production of grass pulp and wood pulp

The question remains whether there are enough grasslands or compensation areas at all? This aspect was also considered and answered in a study initiated by Creapaper GmbH: there are sufficient compensation areas for a multiple of the currently required quantity [8, 10] and there is no competition between using grass for paper versus cattle feed. On the contrary, these meadows are wonderful and particularly diverse food sources for our bees and insects, on which they find pollen and nectar for a long time from spring to summer and into autumn. This is because these areas are only mowed twice a year and very late in the year. And once the grass is mowed, it brings farmers an additional income – a truly sustainable solution which reconciles ecological goals with economic and social aspects.

And if you send your next birthday card, you can use grass paper with incorporated flower seeds to grow a blooming meadow.

Literature:

[1] https://www.creapaper.de/

[2] https://www.spektrum.de/lexikon/chemie/zellstoff/10075

[3] https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/papier_-_wald_und_klima_schuetzen-reichart_1.pdf

[4] https://www.umweltbundesamt.de/daten/ressourcen-abfall/verwertung-entsorgung-ausgewaehlter-abfallarten/altpapier#die-deutsche-papierindustrie

[5] https://www.umweltbundesamt.de/themen/wirtschaft-konsum/produkte/oekobilanz

[6] W. Beier, „Ökologischer Vergleich des Einsatzes von Sulfat-Zellstoff, Altpapierzellstoff, grasbasiertem Zellstoff in der deutschen Papierproduktion“ Internationales Zentrum für Nachhaltige Entwicklung an der Hochschule Bonn-Rhein-Sieg im Auftrag der Creapaper GmbH, 2017 https://www.creapaper.de/wp-content/uploads/2019/03/%C3%96kobilanz_Creapaper-vers.-12.12.2017.pdf

[7] Wellenreuther, F. Vergleichende „Screening-Ökobilanz“ Primärzellstoff, Recyclingfasern und Graspellets zur Papierherstellung“, Institut für Energie – und Umweltforschung (IFEU), Heidelberg im Auftrag von Green.Projekt der C+G Papier GmbH Hennef https://www.creapaper.de/wp-content/uploads/2019/03/Zertifikat-Oekobilanz_Rohstoffe_IFEU_2013.pdf

[8] Entwicklung eines Verfahrens zur Gewinnung von Gras als Rohstoff und Verarbeitung für die Herstellung von Papierprodukten unter besonderer Berücksichtigung des Aufbaus einer nachhaltigen Wertschöpfungskette: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-30990.pdf

[9] Dunkelberg E., Bluhm H., Umweltauswirkungen einer ländlichen Bioökonomie – Lebenszyklusanalyse von drei Wertschöpfungsketten einer Koppel – und Kaskadennutzung von nachwachsenden Rohstoffen, Schriftenreihe des IÖW 216/19

[10] http://www.graspapier.de/faq/#1442834308586-3e09df3f-f8a2

Why grass paper is better than conventional paper

In a nutshell: Grass paper is a green alternative in both senses of the word to conventional paper, using significantly less raw material, being recyclable and compostable. Even if it is a bit more expensive than wood pulp, our nature should be worth it, don't you think?And if you send your next birthday card, you can use grass paper with incorporated flower seeds to grow a blooming meadow.

Literature:

[1] https://www.creapaper.de/

[2] https://www.spektrum.de/lexikon/chemie/zellstoff/10075

[3] https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/papier_-_wald_und_klima_schuetzen-reichart_1.pdf

[4] https://www.umweltbundesamt.de/daten/ressourcen-abfall/verwertung-entsorgung-ausgewaehlter-abfallarten/altpapier#die-deutsche-papierindustrie

[5] https://www.umweltbundesamt.de/themen/wirtschaft-konsum/produkte/oekobilanz

[6] W. Beier, „Ökologischer Vergleich des Einsatzes von Sulfat-Zellstoff, Altpapierzellstoff, grasbasiertem Zellstoff in der deutschen Papierproduktion“ Internationales Zentrum für Nachhaltige Entwicklung an der Hochschule Bonn-Rhein-Sieg im Auftrag der Creapaper GmbH, 2017 https://www.creapaper.de/wp-content/uploads/2019/03/%C3%96kobilanz_Creapaper-vers.-12.12.2017.pdf

[7] Wellenreuther, F. Vergleichende „Screening-Ökobilanz“ Primärzellstoff, Recyclingfasern und Graspellets zur Papierherstellung“, Institut für Energie – und Umweltforschung (IFEU), Heidelberg im Auftrag von Green.Projekt der C+G Papier GmbH Hennef https://www.creapaper.de/wp-content/uploads/2019/03/Zertifikat-Oekobilanz_Rohstoffe_IFEU_2013.pdf

[8] Entwicklung eines Verfahrens zur Gewinnung von Gras als Rohstoff und Verarbeitung für die Herstellung von Papierprodukten unter besonderer Berücksichtigung des Aufbaus einer nachhaltigen Wertschöpfungskette: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-30990.pdf

[9] Dunkelberg E., Bluhm H., Umweltauswirkungen einer ländlichen Bioökonomie – Lebenszyklusanalyse von drei Wertschöpfungsketten einer Koppel – und Kaskadennutzung von nachwachsenden Rohstoffen, Schriftenreihe des IÖW 216/19

[10] http://www.graspapier.de/faq/#1442834308586-3e09df3f-f8a2

Leer más

Leer menos