メニュー

JP | JPY

-

-

-

- Challenges and Chances: A Review of the 1st Stem Cell Community Day

- Summertime, and the Livin’ Is Easy…

- Follow-on-Biologics – More than Simple Generics

- Bacteria Versus Body Cells: A 1:1 Tie

- Behind the Crime Scene: How Biological Traces Can Help to Convict Offenders

- Every 3 Seconds Someone in the World Is Affected by Alzheimer's

- HIV – It’s Still Not Under Control…

- How Many Will Be Convicted This Time?

- Malaria – the Battle is Not Lost

- Physicians on Standby: The Annual Flu Season Can Be Serious

- At the Forefront in Fighting Cancer

- Molecular Motors: Think Small and yet Smaller Again…

- Liquid Biopsy: Novel Methods May Ease Cancer Detection and Therapy

- They Are Invisible, Sneaky and Disgusting – But Today It’s Their Special Day!

- How Many Cells Are in Your Body? Probably More Than You Think!

- What You Need to Know about Antibiotic Resistance – Findings, Facts and Good Intentions

- Why Do Old Men Have Big Ears?

- The Condemned Live Longer: A Potential Paradigm Shift in Genetics

- From Research to Commerce

- Chronobiology – How the Cold Seasons Influence Our Biorhythms

- Taskforce Microbots: Targeted Treatment from Inside the Body

- Eyes on Cancer Therapy

-

-

-

-

- Challenges and Chances: A Review of the 1st Stem Cell Community Day

- Summertime, and the Livin’ Is Easy…

- Follow-on-Biologics – More than Simple Generics

- Bacteria Versus Body Cells: A 1:1 Tie

- Behind the Crime Scene: How Biological Traces Can Help to Convict Offenders

- Every 3 Seconds Someone in the World Is Affected by Alzheimer's

- HIV – It’s Still Not Under Control…

- How Many Will Be Convicted This Time?

- Malaria – the Battle is Not Lost

- Physicians on Standby: The Annual Flu Season Can Be Serious

- At the Forefront in Fighting Cancer

- Molecular Motors: Think Small and yet Smaller Again…

- Liquid Biopsy: Novel Methods May Ease Cancer Detection and Therapy

- They Are Invisible, Sneaky and Disgusting – But Today It’s Their Special Day!

- How Many Cells Are in Your Body? Probably More Than You Think!

- What You Need to Know about Antibiotic Resistance – Findings, Facts and Good Intentions

- Why Do Old Men Have Big Ears?

- The Condemned Live Longer: A Potential Paradigm Shift in Genetics

- From Research to Commerce

- Chronobiology – How the Cold Seasons Influence Our Biorhythms

- Taskforce Microbots: Targeted Treatment from Inside the Body

- Eyes on Cancer Therapy

-

JP | JPY

Sorry, we couldn't find anything on our website containing your search term.

- ホーム

- Products

- バイオプロセス

- Bioprocess Equipment for Commercial Manufacturing

- BioBLU® f HNQ Single-Use Bioreactors

BioBLU® f HNQ Single-Use Bioreactors

製品情報

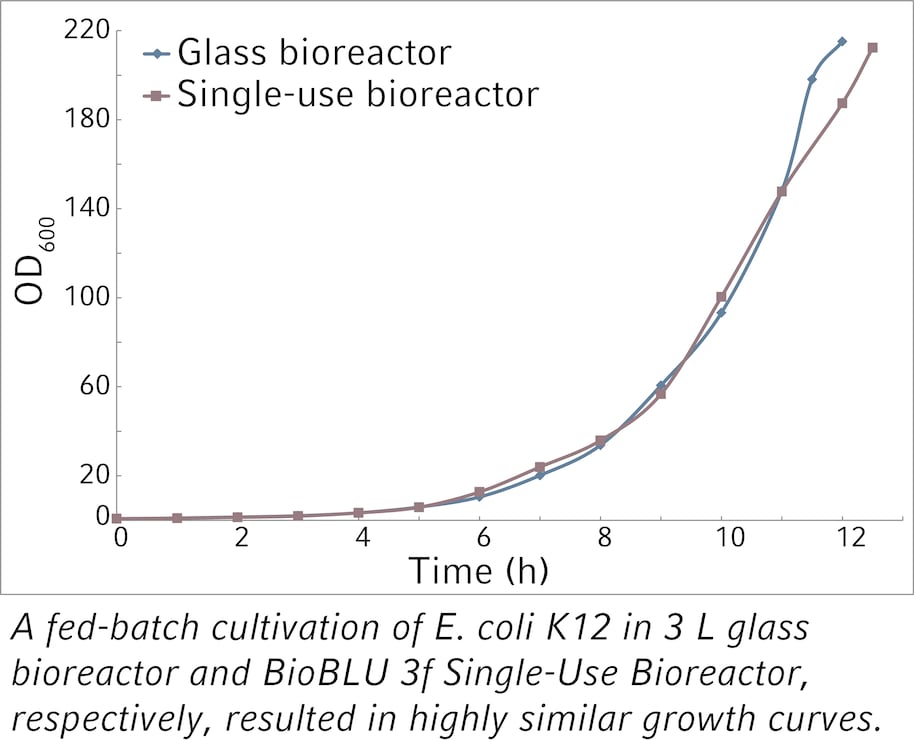

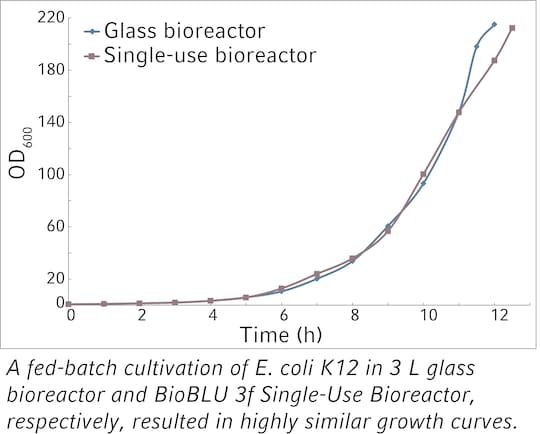

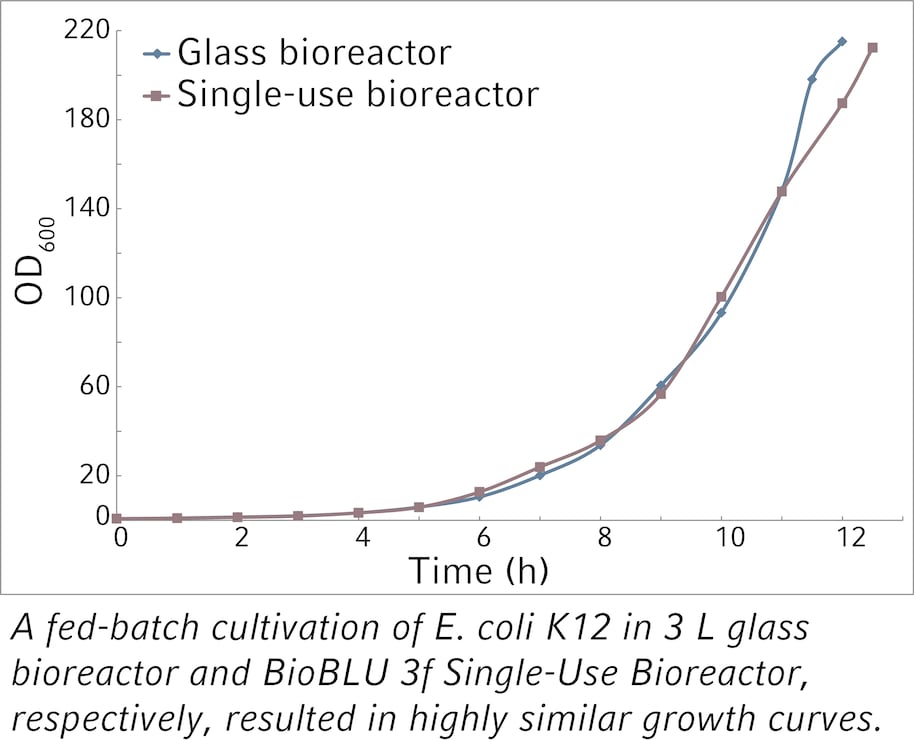

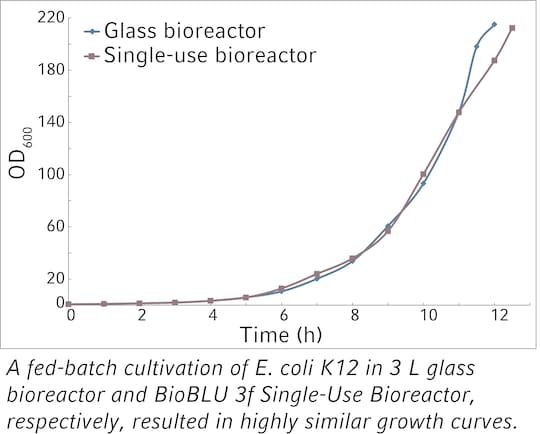

BioBLU f HNQ Single-Use Bioreactors は硬壁攪拌タンクのバイオリアクターで臨床用および商業用製造に適します。それらは、細菌、酵母菌、菌類を使用する強靭な微生物アプリケーションに専用の設計です。拡張可能な BioBLU f HNQポートフォリオは最大 3.75 Lの動作容量をカバーします。硬壁撹拌タンクは、従来のデザインを踏襲し、混合および物質移動を効率化した、高細胞密度発酵に最適のバイオリアクターです。追加でダウンロードできる材料がありますこのページの最後に

製品情報

アプリケーション

特徴

製品情報

HNQ Harmonized for Next-Generation Quality用スタンド、 統一証明書およびValidation Guideドキュメントを伴った製品を納入する弊社のコミットメントを強調しています。(動作容量 320mL – 1.25L) (動作容量 1.25L – 3.75

BioBLU HNQシリーズは顧客対応の品質ドキュメンテーションにおいて飛躍的に前進し、弊社の顧客の設備品質とプロセスバリデーションアクティビティをサポートします。

一目で分かる細胞培養アプリケーション用BioBLU f HNQ Single-Use Bioreactors:

硬壁攪拌タンク設計は従来のデザインを踏襲し、混合および物質移動を効率化した、高密度発酵に最適のバイオリアクターです。

• BioBLU 1f HNQ(動作容量320 mL – 1.25 L)

• BioBLU 3f HNQ (動作容量 1.25 L – 3.75 L)

臨床用と商業用製造での使用に適しています

• BioBLU HNQ Single-Use Bioreactorsにはロット固有のバリデーションガイド、照射認証、滅菌テストおよびエンドトキシンテストレポートがあります。

• 弊社はバイオプロセスコントローラ、バイオリアクター、バイオプロセスSCADAソフトウェア、そしてGMP要件に順じたバイオプロセスのコンプライアンスを共に支援するサービスの総合ソリューションパッケージを提供しています。

警告!医療診断または治療におけるアプリケーション用には認証されていません!シングルユーズベッセルは医療診断または治療におけるアプリケーション用には開発されていません。(EU) 2017/745規定の意味での医療設備ではありません。シングルユーズベッセルを医療または治療アプリケーションに使用しないでください。

Eppendorf Bioprocess Products – application in GMP regulated environment

Download document to find out which features you can expect at minimum from Eppendorf products that are deemed suitable or compatible for GMP.

BioBLU HNQシリーズは顧客対応の品質ドキュメンテーションにおいて飛躍的に前進し、弊社の顧客の設備品質とプロセスバリデーションアクティビティをサポートします。

一目で分かる細胞培養アプリケーション用BioBLU f HNQ Single-Use Bioreactors:

硬壁攪拌タンク設計は従来のデザインを踏襲し、混合および物質移動を効率化した、高密度発酵に最適のバイオリアクターです。

• BioBLU 1f HNQ(動作容量320 mL – 1.25 L)

• BioBLU 3f HNQ (動作容量 1.25 L – 3.75 L)

臨床用と商業用製造での使用に適しています

• BioBLU HNQ Single-Use Bioreactorsにはロット固有のバリデーションガイド、照射認証、滅菌テストおよびエンドトキシンテストレポートがあります。

• 弊社はバイオプロセスコントローラ、バイオリアクター、バイオプロセスSCADAソフトウェア、そしてGMP要件に順じたバイオプロセスのコンプライアンスを共に支援するサービスの総合ソリューションパッケージを提供しています。

警告!医療診断または治療におけるアプリケーション用には認証されていません!シングルユーズベッセルは医療診断または治療におけるアプリケーション用には開発されていません。(EU) 2017/745規定の意味での医療設備ではありません。シングルユーズベッセルを医療または治療アプリケーションに使用しないでください。

Eppendorf Bioprocess Products – application in GMP regulated environment

Download document to find out which features you can expect at minimum from Eppendorf products that are deemed suitable or compatible for GMP.

バイオリアクター本体およびヘッドプレート

• 攪拌タンク構造:攪拌タンク構造は信頼性と拡張性を持ち、伝統的なグラスバイオリアクターの交換を容易にします。

• 設備:BioBLU Single-Use Bioreactors バイオリアクターは、スパージャー、オーバーレイ、出入り口のガスフィルター、および、pH、DO、温度、液体添加、サンプリング、採取用挿入パーツで構成されています。すべてのヘッドプレートは使いやすくするために明確にマーキングされています。スペアのPg13.5ポートにはシングルユーズ隔壁、トリオ隔壁、よりフレキシビルにするためのクランプ締め付けアダプターを装備することができます。ホース:スペアの Pg 13.5 ポートにはシングルユーズ隔壁、トリオ隔壁、よりフレキシビルにするためのクランプ締め付けアダプターを装備することができます。

• 滅菌: BioBLU 1f HNQ Single-Use Bioreactorsは滅菌状態で納品されます。> 25 kGy (X-ray)によって照射済み。SALレベル 10-6、X線照射BioBLU Single-Use Bioreactors用。The BioBLU 3f HNQ Single-Use Bioreactorは前滅菌されておらず、オートクレーブ可能です。

高い細胞密度に適しています。

BioBLU f HNQ Single-Use Bioreactors は高いマストランスファーおよび発酵プロセスのヒートリムーバル要件をサポートします。

• モーター:パワフルないオーバーヘッド駆動によって高い攪拌速度が可能です。完全閉じ込みベアリングによる密封磁力ドライブにより、容器の滅菌性が維持されます。

• バッフル: インテリアバッフルは混合と物質移動を助けます。さらにBioBLU 1f HNQのバッフルはアクティブクーリングによる効率的なヒートリムーバルを供給します。

• インペラ: 複数のラシュトンタイプインペラによる効率的な混合および物質移動。

• 冷却: ク-リングバッフルまたはクーリングフィンガーを使う場合のスマートな解決法

• 排気処理:効果的な液体フリーの排気結露(ペルチェ)または電子加熱テープまたは水冷排気処理。

もっと読む

読む量をもっと少なくする

アプリケーション

- バクテリア、酵母、菌類の発酵

- 高細胞密度発酵に最適

- ヒトと動物の細胞の培養のために、弊社は BioBLU c HNQ Single-Use Bioreactor製品ラインを提供しています。

特徴

- 最大3.75 Lの動作容量のシングルユーズ、攪拌タンク、硬壁バイオリアクター

- 高密度発酵プロセス用設計

- 複数のラシュトンタイプインペラによる卓越した混合および物質移動

- 完全閉じ込みベアリングによる密封磁力ドライブにより、容器の滅菌性が維持されます。

- バッフルによる卓越した混合および物質移動

- バイオリアクターは、スパージャー、出入り口用ガスフィルター、および、pH、DO、温度、液体添加、サンプリング、採取用挿入パーツで構成されています。

- Eppendorfバイオリアクターシステムと併用